Photocuring abrasion-resistant coating having antibacterial performance and preparation method thereof

A wear-resistant coating and light-curing technology, applied in the field of coatings, can solve the problems of mildew on the surface of the coating, reduce the wear resistance of the coating, and easily breed bacteria, achieve excellent anti-corrosion and antibacterial properties, and increase the wear resistance of the coating film. The effect of improving surface scratch resistance and abrasion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

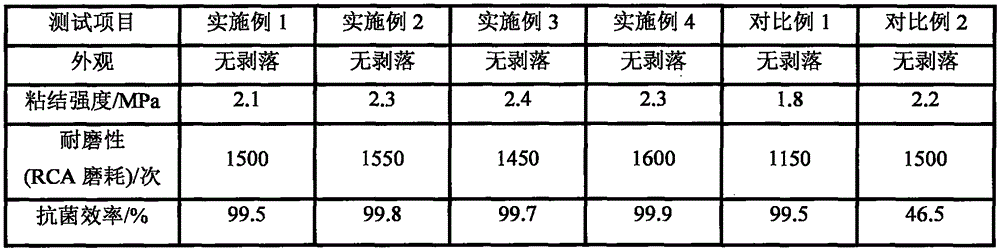

Examples

Embodiment 1

[0023] (1), Weigh 40 parts of epoxy acrylate, 10 parts of aminoethyl vinyl silicone emulsion, 5 parts of bisphenol-A-polyoxyethylene-polyoxypropylene ether, 10 parts of reactive diluent, 10 parts of solvent and 0.5 parts of cellulose are put into a stirring tank, and stirred at a rotating speed of 1000r / min for 20min to obtain a mixture; (2), then take by weighing 6 parts of photoinitiators, 1.2 parts of defoamers, 1.5 parts of fluid Leveling agent, 1.1 parts of matting agent, 0.8 parts of slip agent, 1.1 parts of wetting agent, 0.8 parts of preservative are added to the mixture of step (1) under stirring, and stirred at a speed of 1000r / min for 30min; (3) , Finally, measure 3.0 parts of wear-resistant additives and 4.0 parts of antibacterial agents and add them to the mixture in step (2), and stir in a stirring tank for 30 minutes at 1200 r / min to obtain a light-cured hybrid wear-resistant coating.

Embodiment 2

[0025] (1), Weigh 44 parts of epoxy acrylate, 11 parts of aminoethyl vinyl silicone emulsion, 5 parts of bisphenol-A-polyoxyethylene-polyoxypropylene ether, 15 parts of reactive diluent, 12 parts of solvent and 0.7 parts of cellulose are put into a stirring tank, stirred at a rotating speed of 1000r / min for 20min to obtain a mixture; (2), then take by weighing 6.5 parts of photoinitiator, 1.0 part of defoamer, 1.3 parts of fluid Leveling agent, 1.0 part of matting agent, 0.6 part of slippery agent, 1.0 part of wetting agent, 0.9 part of preservative are added to the mixture of step (1) under stirring, and stirred at a speed of 1000r / min for 30min; (3) , Finally, measure 4.0 parts of wear-resistant additives and 3.5 parts of antibacterial agents and add them to the mixture in step (2), and stir in a stirring tank for 30 minutes at 1200 r / min to obtain a light-cured hybrid wear-resistant coating.

Embodiment 3

[0027] (1), Weigh 48 parts of epoxy acrylate, 12 parts of aminoethyl vinyl silicone emulsion, 5 parts of bisphenol-A-polyoxyethylene-polyoxypropylene ether, 10 parts of reactive diluent, 15 parts of solvent and 1.0 parts of cellulose are put into a stirring tank, and stirred at a rotating speed of 1000r / min for 20min to obtain a mixture; (2), then take by weighing 7.0 parts of photoinitiator, 1.5 parts of defoamer, 1.4 parts of fluid Leveling agent, 1.2 parts of matting agent, 1.0 part of slip agent, 1.2 parts of wetting agent, 0.9 part of preservative are added to the mixture of step (1) under stirring, and stirred for 30 minutes at a speed of 1000r / min; (3) , Finally, measure 2.5 parts of wear-resistant additives and 3.0 parts of antibacterial agents and add them to the mixture in step (2), and stir in a stirring tank for 30 minutes at 1200 r / min to obtain a light-cured hybrid wear-resistant coating.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com