Three-dimensional heat-insulating reinforced concrete liner for mines

A technology of reinforced concrete and concrete, which is applied in shaft lining, tunnel lining, mining equipment, etc., can solve problems such as mine roadway temperature, insufficient heat insulation effect, and uneven spraying, so as to achieve full utilization of compressive strength and meet Roadway heat insulation and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

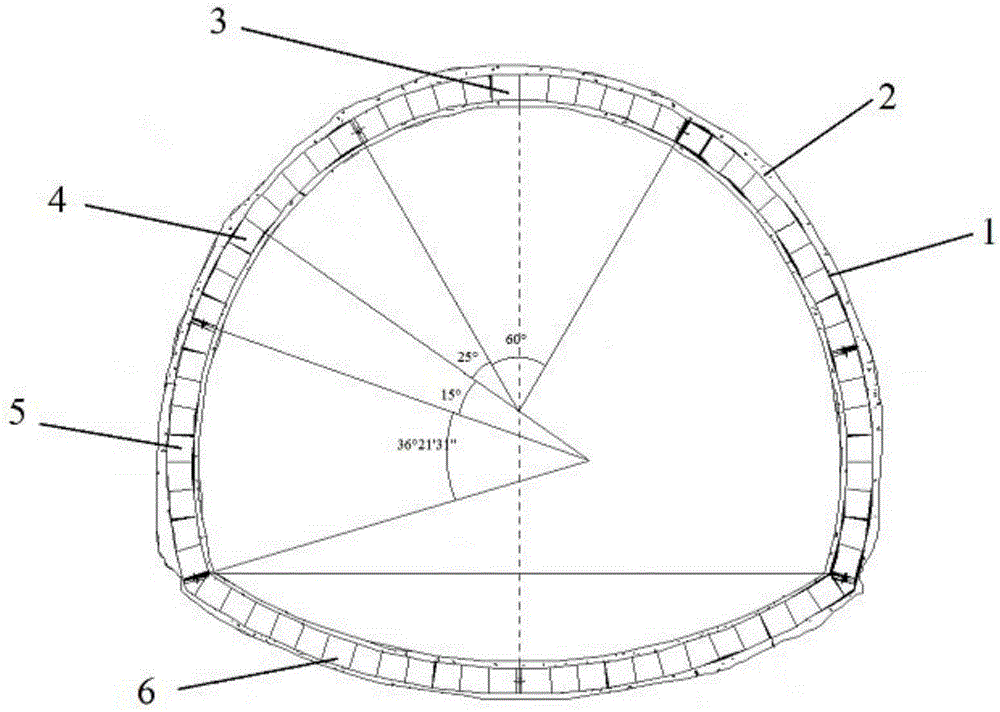

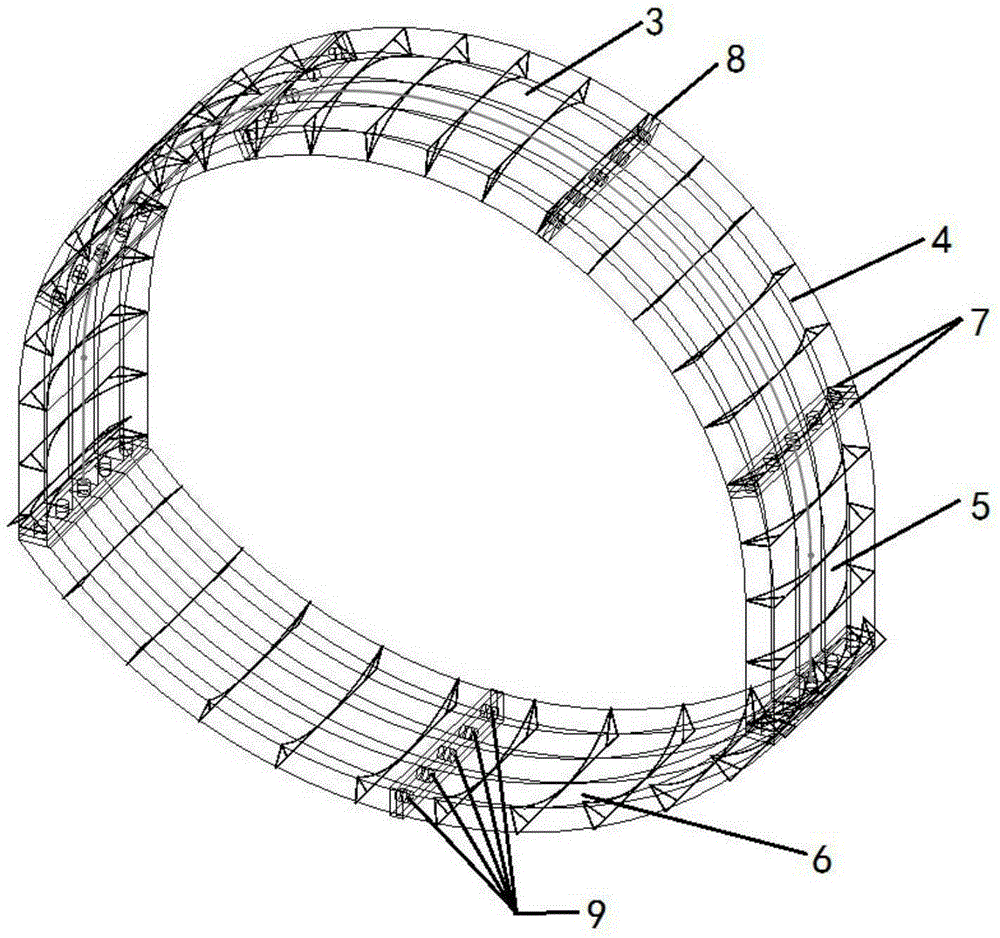

[0033] A heat-insulating three-dimensional reinforced concrete lining for a mine is composed of two parts: a three-dimensional reinforced reticulated shell support (1) and a heat-insulating support concrete sprayed layer (2).

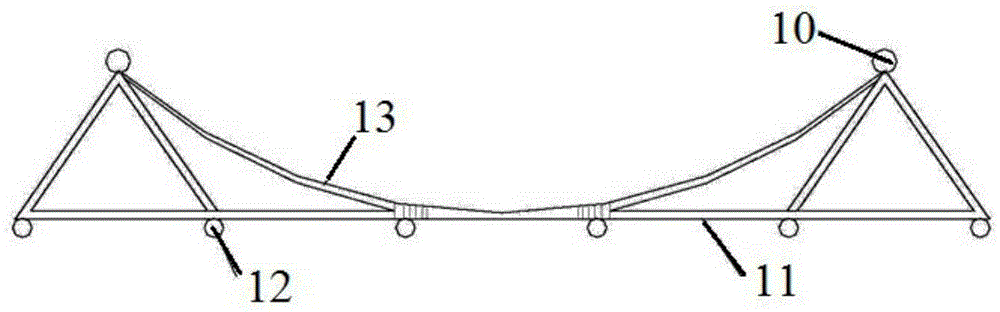

[0034] The three-dimensional reinforced reticulated shell support (1) is a fully enclosed three-core arch, which is divided into 7 reticulated shell members according to the section of the roadway, including 1 top reticulated shell (3), 2 mirrored upper reticulated shells (4), 2 The lower reticulated shell (5) and two bottom reticulated shells (6) are assembled, wherein the central angle of the top reticulated shell (3) is 60°, and the central angle of the upper reticulated shell (4) at 4 / 7 of the arc surface is 25° °, the central angle at 3 / 7 of the arc surface is 15°, the central angle of the lower reticulated shell (5) is 36°21'31", the grid width is 700mm, and each piece is composed of 2 Φ22 main arc ribs (10), 6 Φ20 secondary arc ribs (12), several...

Embodiment 2

[0041] The thermal insulation support concrete spraying layer (2) includes the following raw materials: cementitious material, gravel, sand, water, ceramsite, vitrified microbeads, polypropylene fiber, early strength agent, quick setting agent and water reducing agent. Cementitious material: gravel: sand: water weight ratio is 1:0.78:0.78:0.45. Cementitious materials include cement and fly ash, fly ash accounts for 5% of the total mass of cementitious materials, ceramsite is fly ash ceramsite, particle size is 10-15mm, mass is 10% of stone mass, vitrified micro The beads are hydrophobic vitrified microbeads, the mass is 5% of the mass of the sand, the polypropylene fiber is bundled monofilament polypropylene fiber, the length is 14-18mm, the diameter or equivalent diameter is 3-60μm, and the dosage is 0.95Kg / m3, early strength agent, quick-setting agent, and water reducer are 3.5%, 4%, and 0.6% of the cement mass, respectively.

[0042] Other conditions are identical with em...

Embodiment 3

[0044] The thermal insulation support concrete spraying layer (2) includes the following raw materials: cementitious material, gravel, sand, water, ceramsite, vitrified microbeads, polypropylene fiber, early strength agent, quick setting agent and water reducing agent. Cementitious material: gravel: sand: water weight ratio is 1:0.78:0.78:0.45. Cementitious materials include cement and fly ash. Fly ash accounts for 20% of the total mass of the cementitious material. Hydrophobic vitrified microbeads, the mass is 20% of the mass of the sand, the polypropylene fiber is bundled monofilament polypropylene fiber, the length is 14-18mm, the diameter or equivalent diameter is 3-60μm, and the dosage is 1.5Kg / m3 , Early strength agent, quick-setting agent, and water reducer are 5%, 3%, and 1.1% of the cement mass, respectively.

[0045] Other conditions are identical with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com