A stepped Magnus type wind blade and wind turbine

A technology for wind turbines and blades, which is applied to wind turbines, wind turbines, and control of wind turbines that are consistent with the wind direction, can solve problems such as low power generation efficiency, and achieve the effect of simplifying the structure, improving the efficiency of the unit, and meeting the strength requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

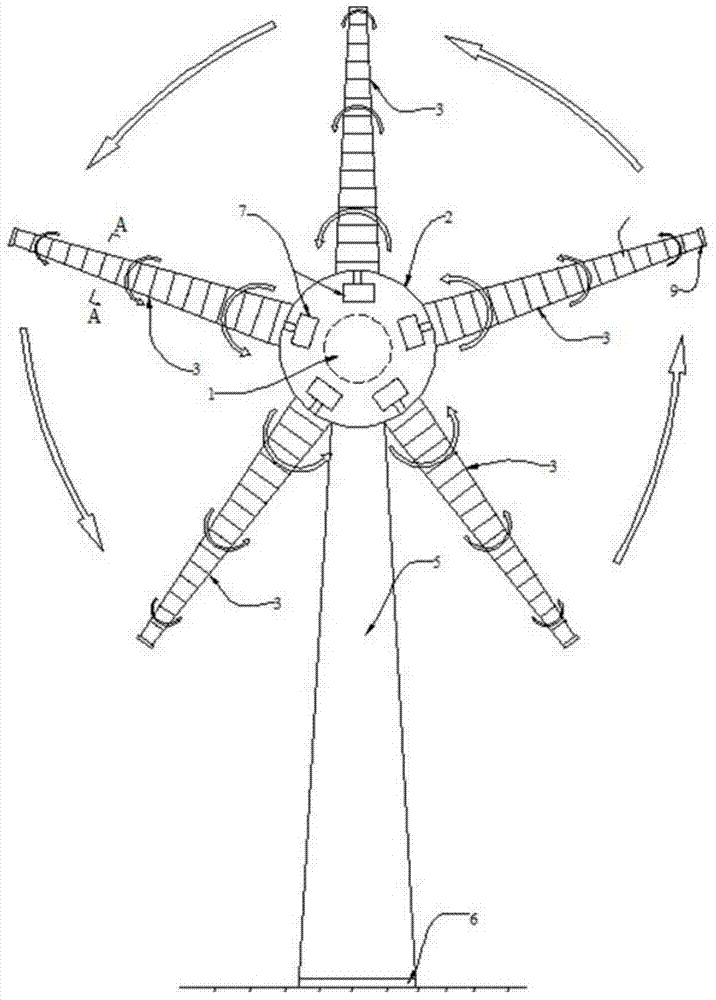

[0027] Such as figure 1 As shown, the Magnus-type wind turbine with stepped self-rotating cylindrical blades includes power generation device (1), hub (2), blades (3), tower (5), foundation (6) and other related facility. The wind wheel consists of blades (3) and a hub (2). The blades (3) have an aerodynamic shape, generate torque to drive the wind wheel to rotate under the action of the airflow, and input the torque to the power generation device (1) through the hub (2). The power generating device (1) converts mechanical energy into kinetic energy and transmits it to the grid. For the convenience of reinforcement, the foundation (6) is square in shape. The tower (5) is connected with the foundation (6), supports the wind power generation system in the air, bears various loads caused by the operation of the wind power generation system, and transmits these loads to the foundation at the same time, so that the whole wind power unit can operate stably and reliably.

[0028]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com