Degradable microstructure body and preparation method thereof

A technology of microstructures and microneedles, which is applied in the fields of biomedicine and medical cosmetology, can solve the problems of rapid degradation of microstructures, poor user experience, and inability to achieve long-term sustained release, and achieve easy preparation and excellent experience Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

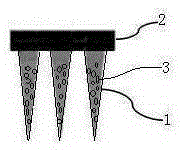

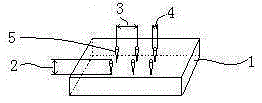

Image

Examples

Embodiment 1

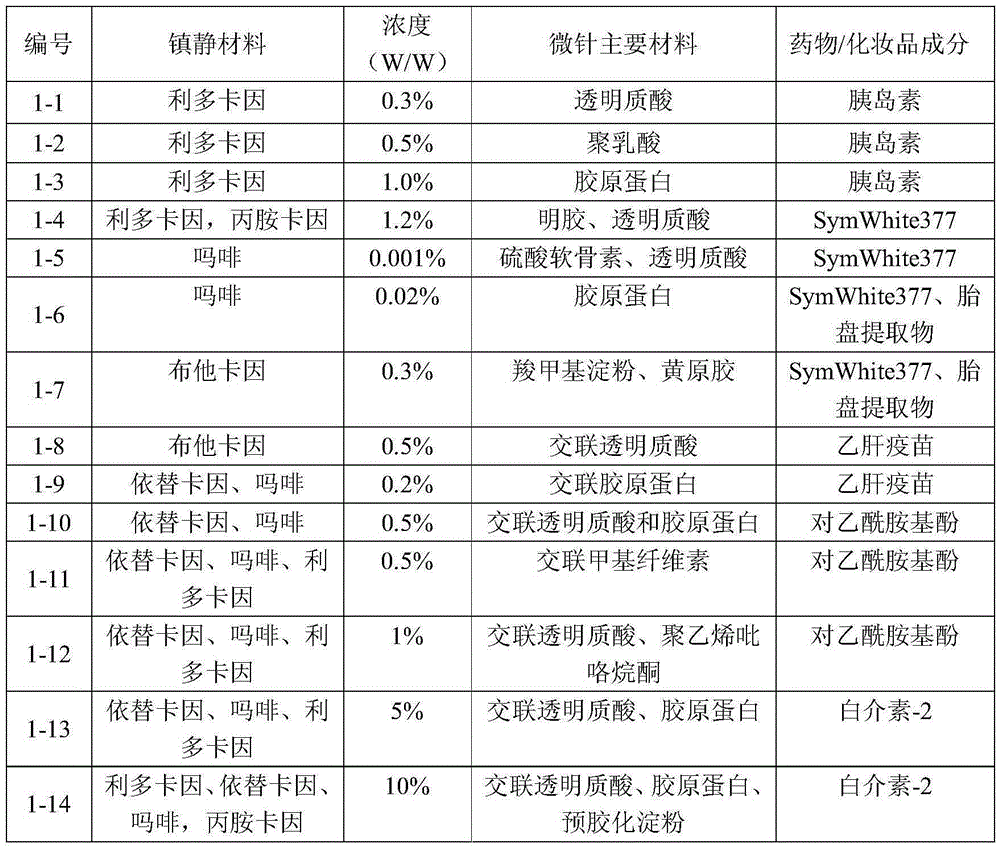

[0023] Example 1: Properties of Microstructures

[0024] In this experiment, the main components of the base of the microstructure are chitosan and dextrin, the diameter of the microneedle, the length of the microneedle and the center distance of the microneedle are 150 μm, 0.5 mm and 0.1 mm, respectively, the pH of the microstructure is 7.1, and the Other parameters of the structure are shown in Table 1.

[0025] Table 1.

[0026]

Embodiment 2

[0027] Example 2: Sensitivity of Microstructures

[0028] In this experiment, the main components of the base of the microstructures are ethyl hydroxyethyl cellulose, polylactic acid and hydroxymethyl cellulose, without drug or cosmetic ingredients. The diameter, length and center distance of microneedles are respectively are 120 μm, 0.5 mm and 0.1 mm, the pH of the microstructure is 7.3, and other performance parameters of the microstructure are shown in Table 2. Note: The microstructures feel the intensity when they are inserted into the skin and the duration after insertion. The feeling is divided into: poor, poor, general, better, good, and good.

[0029] Table 2

[0030]

[0031]

Embodiment 3

[0032] Example 3: Degradation performance of microstructures

[0033] In this experiment, the degradation performance of several microstructures was compared. The substrate was polylactic acid-glycolic acid, the diameter of the microneedles, the length of the microneedles and the distance between the centers of the microneedles were 100 μm, 0.6 mm and 0.15 mm, respectively, and the pH of the microstructures was 7.5, other performance parameters are shown in Table 3.

[0034] 0.5 g of microstructured microneedles were put into 1 ml centrifuge tubes, and 200 μl of hyaluronidase and / or collagenase solution was added to each tube so that the concentration of the enzyme was 30 IU / ml. The sample without enzyme addition and other operations kept the same as the control. 37°C constant temperature for 16 hours. After the reaction, each tube was centrifuged, the supernatant was discarded, and the weight of the sample remaining at the bottom of the tube was determined. The weight meas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com