Method for treating polyether polyol process wastewater

A polyether polyol and waste water technology, which is applied in multi-stage water treatment, aerobic process treatment, natural water body treatment, etc., can solve the problems of complex process flow and increased sewage treatment cost, and achieve the effect of reducing the content of organic matter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

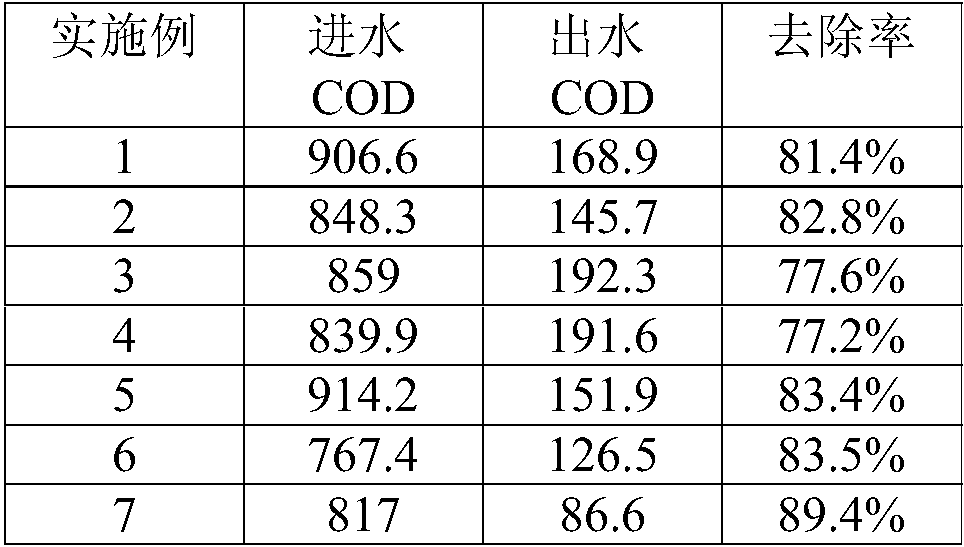

Examples

Embodiment 1

[0022] 1. Drug preparation:

[0023] Preparation of 15% polyaluminum chloride (PAC): first put 100Kg of polyaluminum chloride into the drug-dissolving tank, stir and fill up with tap water, and stir for 0.5h.

[0024] Prepare 0.1% polyaluminum chloride (PAM): first fill the medicine dissolving tank with tap water, slowly add 1Kg of polyacrylamide under stirring condition, and stir for at least 1 hour.

[0025] 2. Steps:

[0026] (1) Regulate polyether polyol waste water pH value with hydrochloric acid solution and be 3, adopt catalyzer to carry out pretreatment then, make the B / C ratio of waste water be 0.51; Described catalyzer is the alumina, magnesia that mass ratio is 95:5 The composition of the catalyst accounts for 0.1% of the total amount of polyether polyol wastewater;

[0027] (2) Use sodium hydroxide solution to adjust the pH value of the wastewater treated in step (1) to 7.8, enter the sludge biochemical tank, and control the dissolved oxygen concentration of 0.71...

Embodiment 2

[0030] 1. Drug preparation as in Example 1.

[0031] 2. Steps:

[0032] (1) Regulate polyether polyol waste water pH value with hydrochloric acid solution and be 3.5, adopt catalyzer to carry out pretreatment then, make the B / C ratio of waste water be 0.53; Described catalyzer is the alumina, magnesia that mass ratio is 95:5 The composition, the catalyst accounts for 0.23% of the total amount of polyether polyol wastewater;

[0033] (2) Use sodium hydroxide solution to adjust the pH value of the wastewater treated in step (1) to 7.6, enter the sludge biochemical tank, and control the dissolved oxygen concentration of 0.78mg / L, pH value of 7.3, ORP value of 85mV and hydraulic retention Time 21h, and add polyaluminum chloride, polyacrylamide, ammonium chloride to stir, finally add catalyst; Among them, the mass ratio of polyaluminum chloride, polyacrylamide, ammonium chloride is 1:1:1, polychloride The sum of the mass of aluminum chloride, polyacrylamide and ammonium chloride ...

Embodiment 3

[0036] 1. Drug preparation as in Example 1.

[0037] 2. Steps:

[0038] (1) regulate polyether polyol waste water pH value with hydrochloric acid solution and be 5, adopt catalyst to carry out pretreatment then, make the B / C ratio of waste water be 0.55; Described catalyzer is the alumina, magnesia that mass ratio is 95:5 The composition, the catalyst accounts for 0.28% of the total amount of polyether polyol wastewater;

[0039] (2) Use sodium hydroxide solution to adjust the pH value of the wastewater treated in step (1) to 7.4, and then enter the sludge biochemical tank to control the dissolved oxygen concentration of 0.79mg / L, pH value of 7.5, ORP value of 80mV and hydraulic retention Time 25h, and add polyaluminum chloride, polyacrylamide, ammonium chloride to stir, finally add catalyst; Among them, the mass ratio of polyaluminum chloride, polyacrylamide, ammonium chloride is 2:1:1, polychloride The sum of the mass of aluminum chloride, polyacrylamide and ammonium chlor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| chemical oxygen demand (mass) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com