Preparation method of acrylic emulsion for construction sealant

A technology of acrylic emulsion and sealing paste, which is applied in the direction of chemical instruments and methods, adhesive types, and other chemical processes, and can solve problems such as unsuitability, aging performance, water resistance, and alkali resistance, etc., to achieve water resistance And the effect of strong toughness, strong adhesion and excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

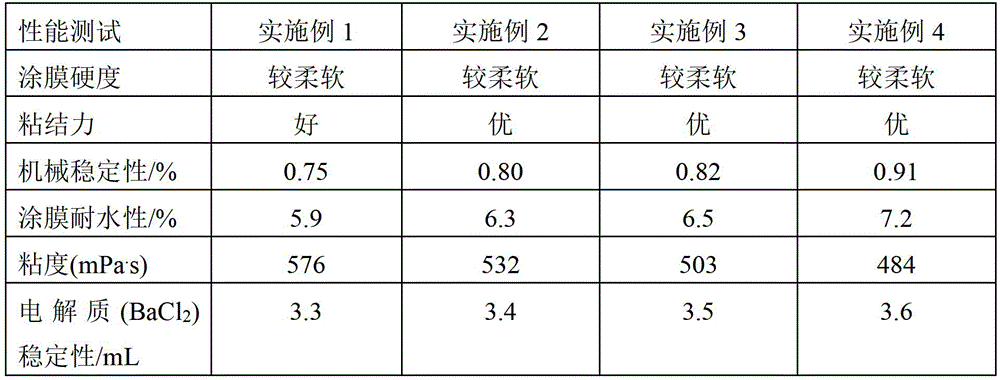

Examples

Embodiment 1

[0018] (1) Preparation of pre-emulsion: the composite emulsifier made of 2g sodium dodecylbenzene sulfonate and 1g nonylphenol polyoxyethylene ether is added to 40g butyl acrylate, 33g methyl methacrylate, 2g acrylic acid In the prepared mixed solution, adjust its pH to 6 with sodium hydroxide, raise the temperature to 60°C in the reactor for emulsification, and add 150g of deionized water dropwise, emulsify for 30min after the dropwise addition, cool down, and pour it into into the beaker;

[0019] (2) Preparation of seed emulsion: Weigh 2g potassium persulfate and 0.2g sodium bicarbonate to make 20mL solution, add to the pre-emulsion and mix evenly, and add 60mL of the emulsion into the reactor, stir at a medium speed, and heat up to 75°C, react for 1 hour to obtain seed emulsion;

[0020] (3) Emulsion polymerization: Add the remaining emulsion liquid dropwise into the seed emulsion within 2 hours to carry out emulsion polymerization reaction, add 0.1 g of potassium persulf...

Embodiment 2

[0022] (1) Preparation of pre-emulsion: the compound emulsifier that 2.4g sodium dodecylbenzene sulfonate and 1.2g nonylphenol polyoxyethylene ether is made into joins by 46g butyl acrylate, 38g methyl methacrylate, In the mixture made of 2.2g of acrylic acid, adjust the pH to 6.5 with sodium hydroxide, raise the temperature in the reactor to 65°C and stir for emulsification, and add 155g of deionized water dropwise, emulsify for 35min after the dropwise addition, and cool down. Pour it into a beaker;

[0023] (2) Preparation of seed emulsion: Weigh 2.3g of potassium persulfate and 0.23g of sodium bicarbonate to make 23mL solution, add it to the pre-emulsion and mix evenly, and add 60mL of the emulsion into the reactor, stir at a medium speed, and heat up to 76°C, react for 1 hour to obtain seed emulsion;

[0024] (3) Emulsion polymerization: drop the remaining emulsion into the seed emulsion within 2 hours for emulsion polymerization, add 0.1g of potassium persulfate / 10mL of...

Embodiment 3

[0026] (1) Preparation of pre-emulsion: the compound emulsifier that 2.6g sodium dodecylbenzene sulfonate and 1.3g nonylphenol polyoxyethylene ether is made into joins by 50g butyl acrylate, 41g methyl methacrylate, In the mixture made of 2.4g of acrylic acid, adjust the pH to 6.2 with sodium hydroxide, raise the temperature in the reactor to 62°C and stir for emulsification, and add 160g of deionized water dropwise, emulsify for 40min after the dropwise addition, and cool down Pour it into a beaker;

[0027] (2) Preparation of seed emulsion: Weigh 2.5g of potassium persulfate and 0.25g of sodium bicarbonate to make 25mL solution, add it to the pre-emulsion and mix evenly, and add 60mL of the emulsion into the reactor, stir at a medium speed, and heat up to 78°C, and react for 1 hour to obtain a seed emulsion;

[0028] (3) Emulsion polymerization: drop the remaining emulsion into the seed emulsion within 2 hours for emulsion polymerization, add 0.1 g of potassium persulfate / 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com