Preparation method for high-strength artificial turf polyurethane gum

A technology of artificial turf and polyurethane, applied in the direction of polyurea/polyurethane adhesives, adhesives, adhesive types, etc., can solve the problems of low pull-out force and hinder the application of high-end sports grass, and achieve long service life and brightness Good appearance, flexibility and toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] This embodiment 1 provides a preparation method of high-strength polyurethane artificial turf adhesive, and prepares an artificial turf adhesive suitable for high-end sports grass, which meets the high pull-out force requirement of sports grass, reaching more than 70N. The preparation method specifically includes:

[0051] Preparation of hydroxyl-terminated polyurethane prepolymer:

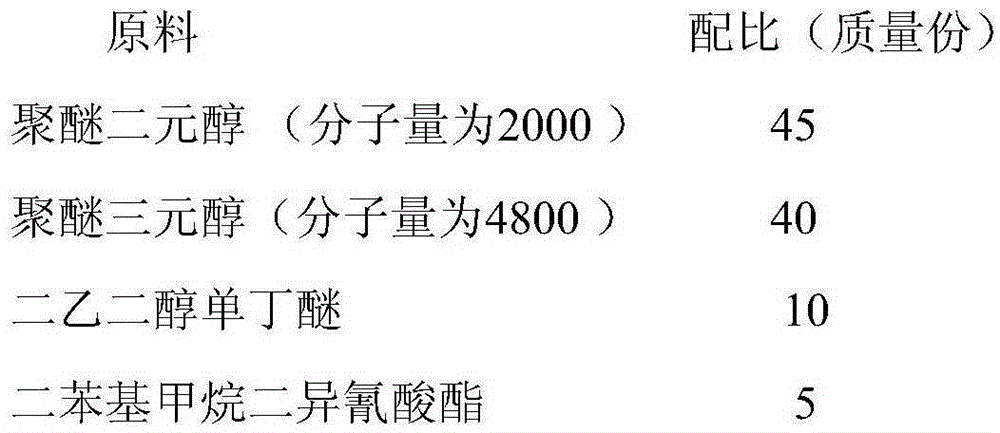

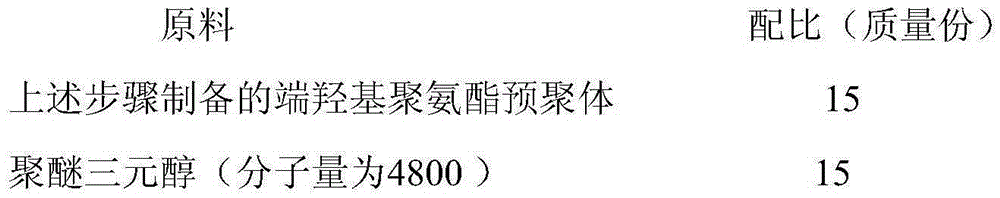

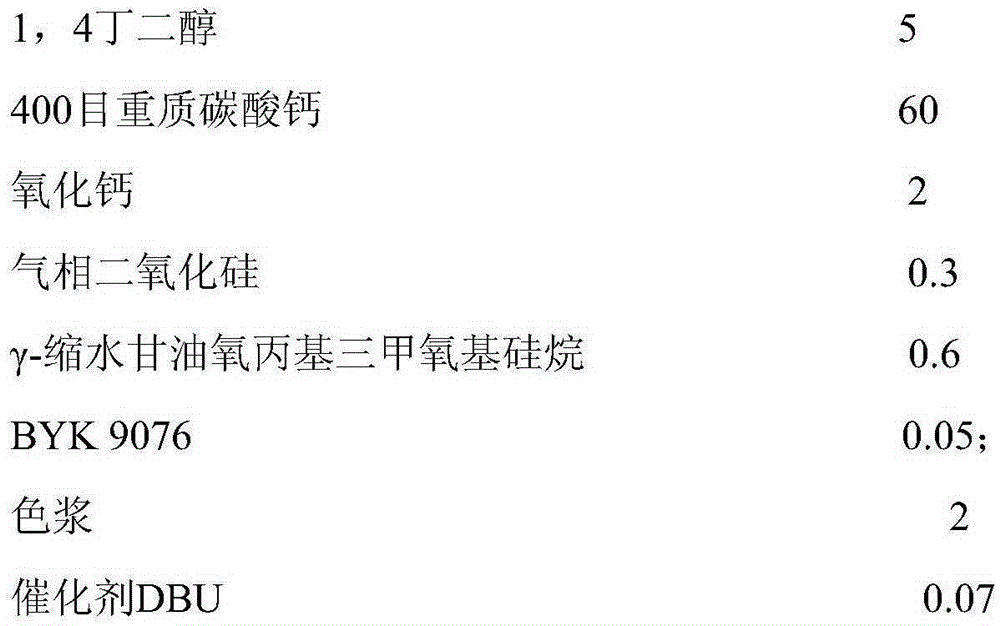

[0052] Get raw materials according to the following ratio:

[0053]

[0054] Add 10 parts by mass of diethylene glycol monobutyl ether, 45 parts by mass of polyether diol and 40 parts by mass of polyether triol into the synthesis reactor, raise the temperature to 50°C, turn off the heating, and put 5 parts by mass of Parts of diphenylmethane diisocyanate was quickly added to the synthesis reactor, kept at 80°C, condensed and refluxed for 5 hours, and the viscosity of the reaction product was measured to be 2500mPa·s (at 25°C), and the hydroxyl value was 18. The synthesis reaction is co...

Embodiment 2

[0064] This embodiment 2 provides a preparation method of high-strength polyurethane artificial turf adhesive, and prepares an artificial turf adhesive suitable for high-end sports grass, which meets the high pull-out force requirement of sports grass, reaching more than 70N. The preparation method specifically includes:

[0065] Preparation of hydroxyl-terminated polyurethane prepolymer:

[0066] Get raw materials according to the following ratio:

[0067]

[0068] Add 12 parts by mass of propylene glycol monobutyl ether, 40 parts by mass of polyether diol and 40 parts by mass of polyether triol into a synthesis reactor, raise the temperature to 50°C, turn off the heating, and put 8 parts by mass of diol Phenylmethane diisocyanate was quickly added to the synthesis reaction kettle, and the temperature was kept at 80°C, condensed and refluxed for 5 hours. The measured viscosity of the reaction product was 2300mPa·s (at 25°C), and the hydroxyl value was 25. The synthesis re...

Embodiment 3

[0077] The third embodiment provides a preparation method of high-strength polyurethane artificial turf adhesive, and prepares an artificial turf adhesive suitable for high-end sports grass, which meets the high pull-out force requirement of sports grass and reaches more than 70N. The preparation method specifically includes:

[0078] Preparation of hydroxyl-terminated polyurethane prepolymer:

[0079] Get raw materials according to the following ratio:

[0080]

[0081] Add 15 parts by mass of dipropylene glycol monobutyl ether, 40 parts by mass of polyether diol and 35 parts by mass of polyether triol into the synthesis reactor, raise the temperature to 50°C, turn off the heating, and add 10 parts by mass of Diphenylmethane diisocyanate was quickly added to the synthesis reaction kettle, and the temperature was kept at 80°C, and condensed and refluxed for 5 hours. Completion, obtained hydroxyl-terminated polyurethane prepolymer;

[0082] To prepare the first component,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Pulling force | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com