Integrated membrane treatment and recovery technology and apparatus for waste acid in production process of titanium dioxide

A production process and recovery device technology, applied in the direction of filtration treatment, multi-stage water treatment, water/sewage treatment, etc., can solve the problems that cannot be achieved and cannot be made into high-concentration pure sulfuric acid, so as to reduce the concentration, save costs, Reduces clogging and damage effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

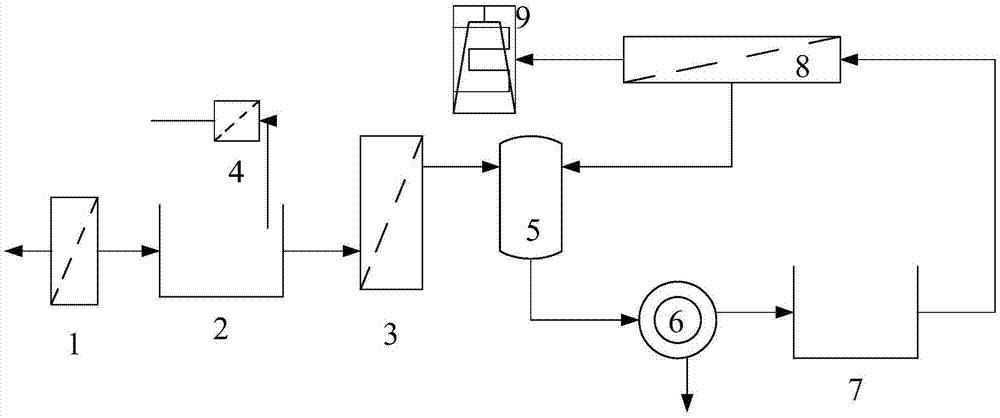

[0053] After the waste acid passes through the pre-filter 1, it enters the waste acid storage tank 2, and then is sent to the first filter 3 for solid-liquid separation, which uses a ceramic membrane with a pore size of 0.2 μm. When the content of titanic acid reaches 200g / L, the metatitanic acid is recovered by the third filter 4 (using a plate and frame filter press), and the filtrate of the plate and frame filter press is returned to the waste acid storage tank 2 and the ceramic membrane is used to recover the metatitanic acid again. Waste acid.

[0054] The waste acid clear liquid filtered by the ceramic membrane enters the crystallization device 5, and the freezing and crystallization temperatures are controlled at -6°C, -2°C, and 2°C, respectively. The frozen and crystallized crystal mixed slurry is vacuum filtered by the second filter (disc filter) 6, and the vacuum degree is controlled at 0.07MPa to obtain ferrous sulfate crystals and crystallization mother liquor. Af...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com