Catalytic cracking method of naphtha feedstock

A catalytic cracking and naphtha technology, which is applied in the field of catalytic cracking of naphtha raw materials, can solve the problems of constant or reduced yield, and achieve the effect of increasing yield and improving economy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0077] According to an embodiment of the present invention, the olefin-rich C4 separated during the product separation process may be injected into the first reaction zone and / or the second reaction zone to participate in the reaction again. The olefin-rich C4 that can be recycled by injecting into the first reaction zone and / or the second reaction zone can account for more than 20% by weight, preferably 50% by weight, of the total amount of olefin-rich C4 separated during the product separation process above.

[0078] In the method provided by the present invention, the temperature of the first catalytic cracking catalyst may be 560-650°C, the temperature of the second catalytic cracking catalyst may be 660-760°C, and the second catalytic cracking catalyst The temperature may be 10-150°C higher than the temperature of the first catalytic cracking catalyst. In the present invention, each of the first catalytic cracking catalyst and the second catalytic cracking catalyst may b...

Embodiment 1

[0101]This example is to illustrate the catalytic cracking effect of the method provided by the present invention after the raw material naphtha 1 is sequentially entered into two reaction zones and under respective reaction conditions.

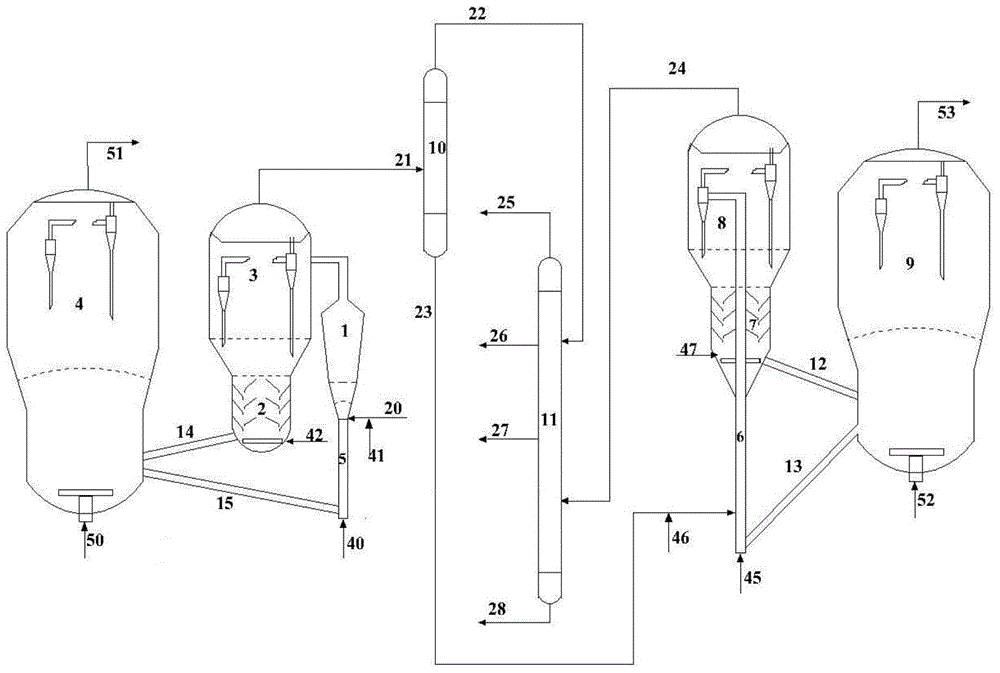

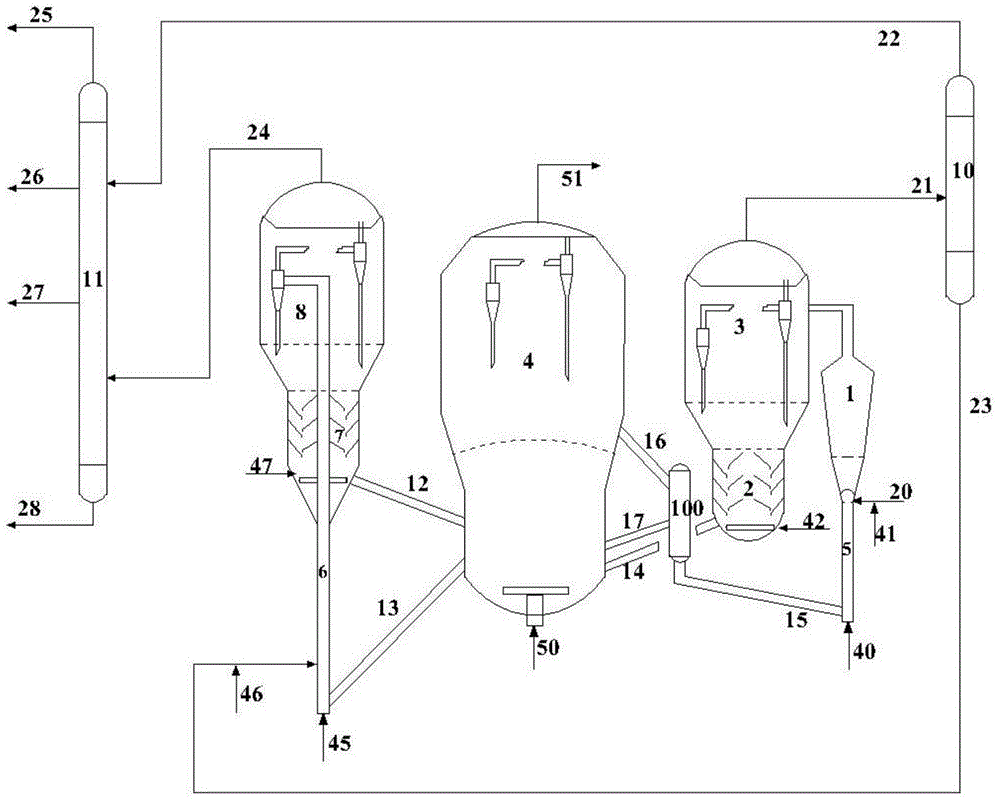

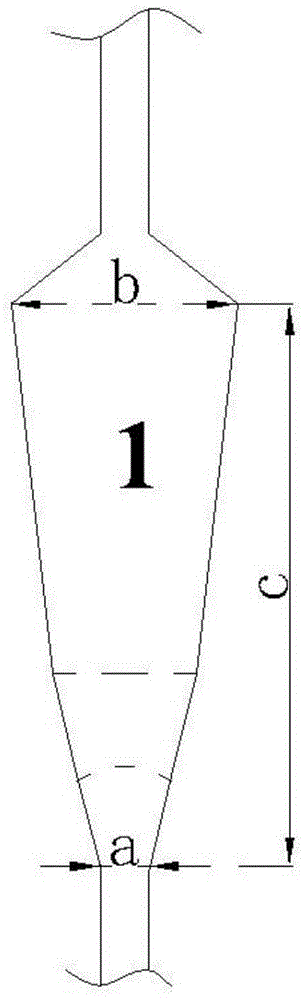

[0102] The experiment was carried out on a catalytic cracking unit with a medium-sized fluidized bed and a riser. Such as figure 1 Shown, the internal diameter of catalyst delivery pipe 5 in this medium-sized device is 16 millimeters, and length is 160 millimeters, and catalyst delivery pipe 5 outlets connect the fluidized bed reactor 1 of gradually expanding diameter, and the lower end internal diameter of fluidized bed reactor 1 is 16 millimeters. mm, the inner diameter of the upper end is 104 mm, and the height is 392 mm. The inner diameter of the riser reactor 6 is 16 mm, and the length is 3800 mm. The test is operated in a single pass mode.

[0103] The first catalytic cracking catalyst at 640°C is introduced into the bottom of the cata...

Embodiment 2

[0107] Catalytic cracking of naphtha 1 is carried out according to the method of embodiment 1, and the experimental device adopted is the same as embodiment 1, and the difference is that the reaction temperature of the riser reactor is increased to 645 ° C, and the regeneration of the second regenerator is carried out simultaneously The temperature was raised to 710°C. The operating parameters and product analysis results in the experiment are shown in Table 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average pore size | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com