Angle broadband extreme ultraviolet multi-layer film having spectrum purification function

A spectral purification, multi-layer film technology, applied in the field of angle broadband extreme ultraviolet multi-layer film, can solve the problems of high cost, limited processing method of microstructure spectral purification technology, low success rate, etc., to reduce reflectivity and suppress spectrum. Purification function, simple structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

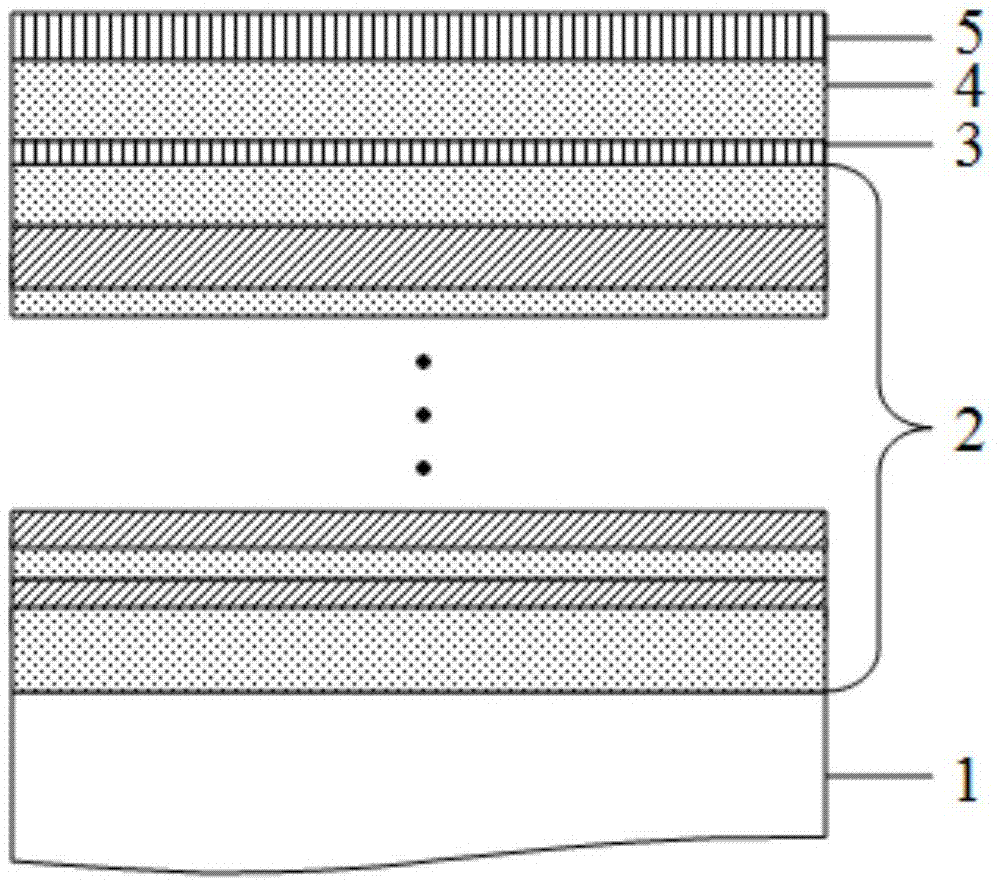

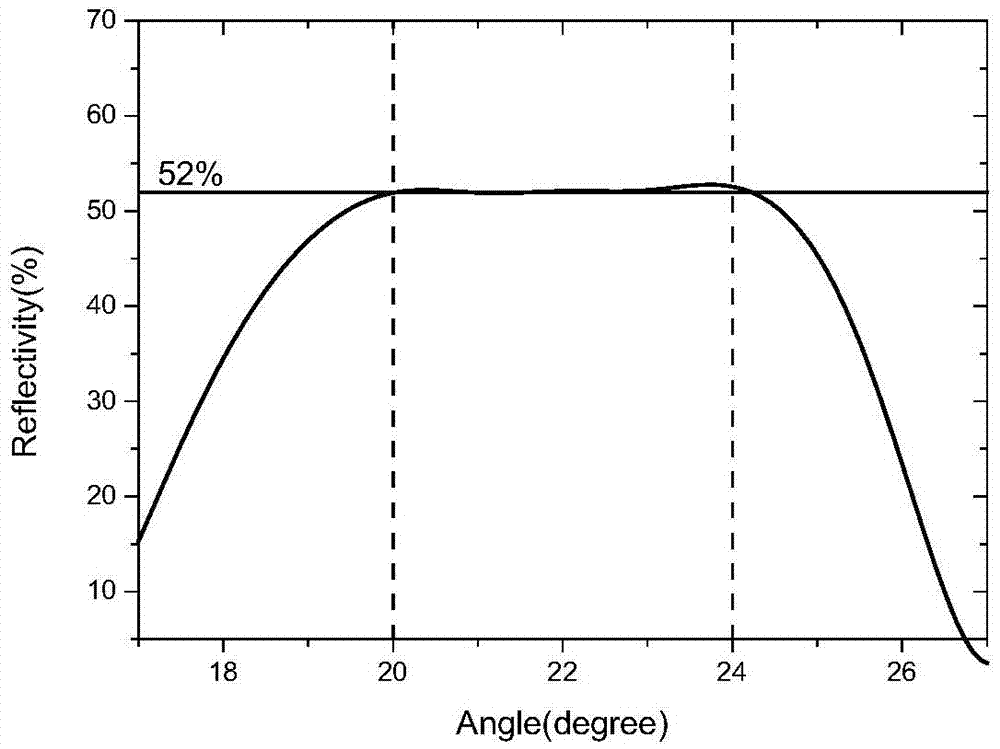

[0026] A non-periodic angular broadband EUV multilayer film 6 is designed by using film system design software. The substrate 1 is made of Si, and the optimization goal is to have as high a reflectivity as possible for a wavelength of 13.5nm in the range of 20° to 24°. A set of film structure is obtained, and its reflectivity is as follows figure 2 shown.

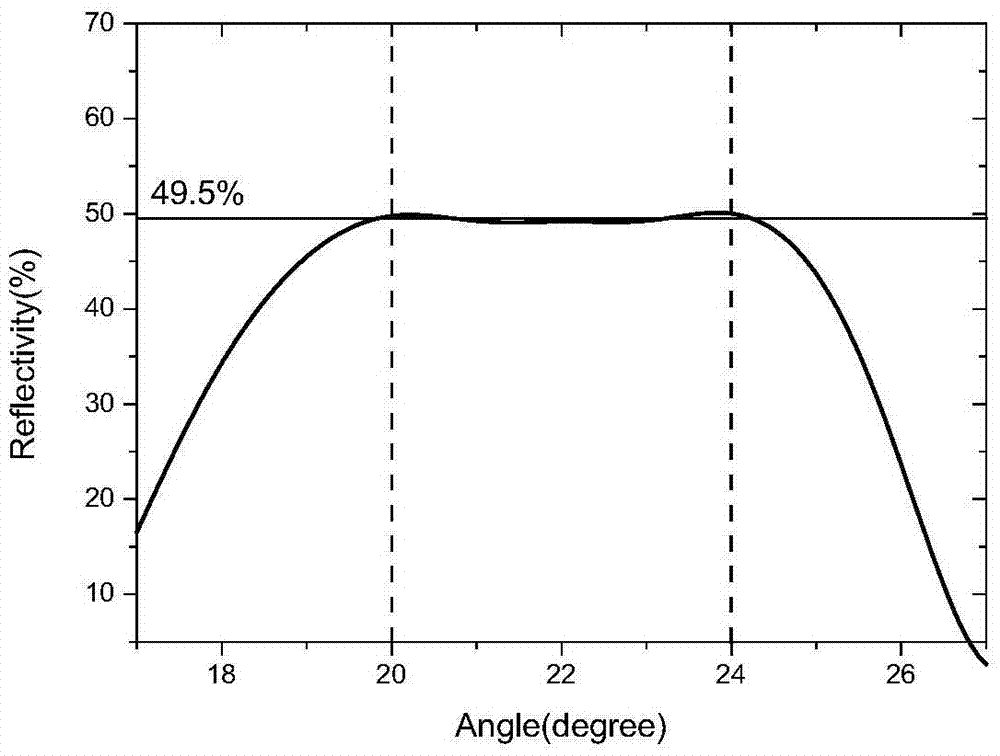

[0027] The thickness of the three surface layers (from top to bottom) of the film structure is 3.035nmMo, 4.438nmSi, and 3.156nmMo, and then the surface three layers are replaced by C, Si, C three-layer structure in turn, and the three-layer structure The thickness is optimized to obtain the thickness of the second spectral absorption layer C5 is 2.359nm, the thickness of the spacer layer Si4 is 4.751nm, the thickness of the spectral absorption layer C3 is a film structure of 2.404nm, and its reflectivity is as follows image 3 shown.

[0028] In order to specifically illustrate that the film structure has the function o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| reflectance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com