Quantum dot electroluminescent device, display apparatus comprising the deivce and illumination apparatus comprising the device

An electroluminescent device and quantum dot light-emitting technology, which is applied in the direction of electric solid-state devices, electrical components, semiconductor devices, etc., can solve problems such as charge injection imbalance, and achieve improved luminous efficiency, high recombination efficiency, and extended brightness half-life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

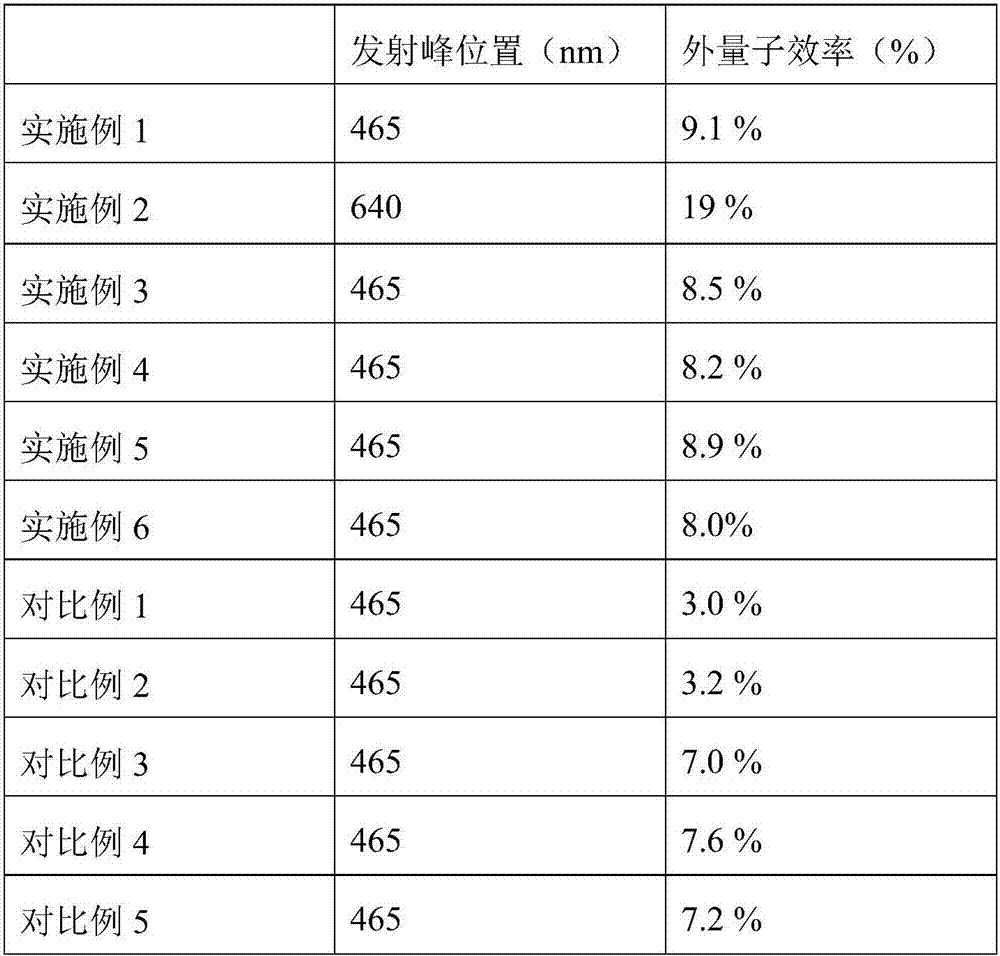

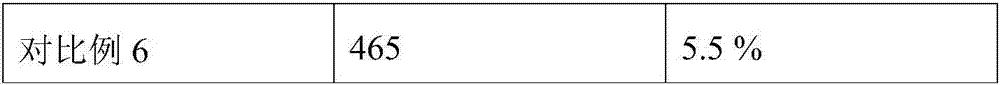

Examples

Embodiment 1

[0042] 1) Clean the anode ITO (indium tin oxide) with a thickness of 200nm.

[0043] Ultrasonic cleaning with ethanol, deionized water and acetone for 10 min, followed by N 2 Dry the liquid adhering to the surface of the glass, and undergo ozone-ultraviolet treatment for 10 minutes to remove impurities on the surface of the ITO.

[0044] 2) Making the first functional layer.

[0045] In an air environment, spin-coat PEDOT:PSS (polystyrene sulfonic acid solution) on a clean ITO transparent conductive glass at a speed of 3000 rpm for 45 seconds. After the spin coating is completed, it is annealed at 140° C. for 30 minutes in the air. Then transfer it to a glove box in a nitrogen atmosphere, anneal at 100°C for 40 minutes, and finally form a layer of PEDOT:PSS on the surface of ITO, that is, form a hole injection layer. Then spin-coat UGH-1 (diphenyl-p-di-o-tolylsilane) chlorobenzene solution (concentration: 8 mg / ml) on the PEDOT:PSS layer at a speed of 2000 rpm for 45 seconds...

Embodiment 2

[0056] The difference with embodiment 1 is: the concentration of PMMA acetone solution is 0.125mg / ml in the making process of the first charge adjustment layer, and the thickness of the first charge adjustment layer formed is 1nm; Quantum dot is red light quantum dot, and emission wavelength is 640nm. Spin-coat a layer of Zn on the second charge regulation layer during the fabrication of the second functional layer 0.95 Mg 0.05 O ethanol solution (concentration is 60mg / ml), the rotating speed is 2000 rpm, and the spin coating time is 45 seconds.

Embodiment 3

[0058] The difference from Example 1 is that the concentration of the PMMA ethyl benzoate solution is 2 mg / ml during the preparation process of the first charge adjustment layer, and the formed thickness is 16 nm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com