Method for preparing fish and pork composite sausages through microorganism mixed fermenting agent

A technology of mixing fermentation agents and microorganisms, which is applied in the field of fermented food, can solve the problems of inferior texture to pork sausage, poor development, single color, etc., and achieve improved nutritional value and edibility, easy storage and carrying, and high nutritional value Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

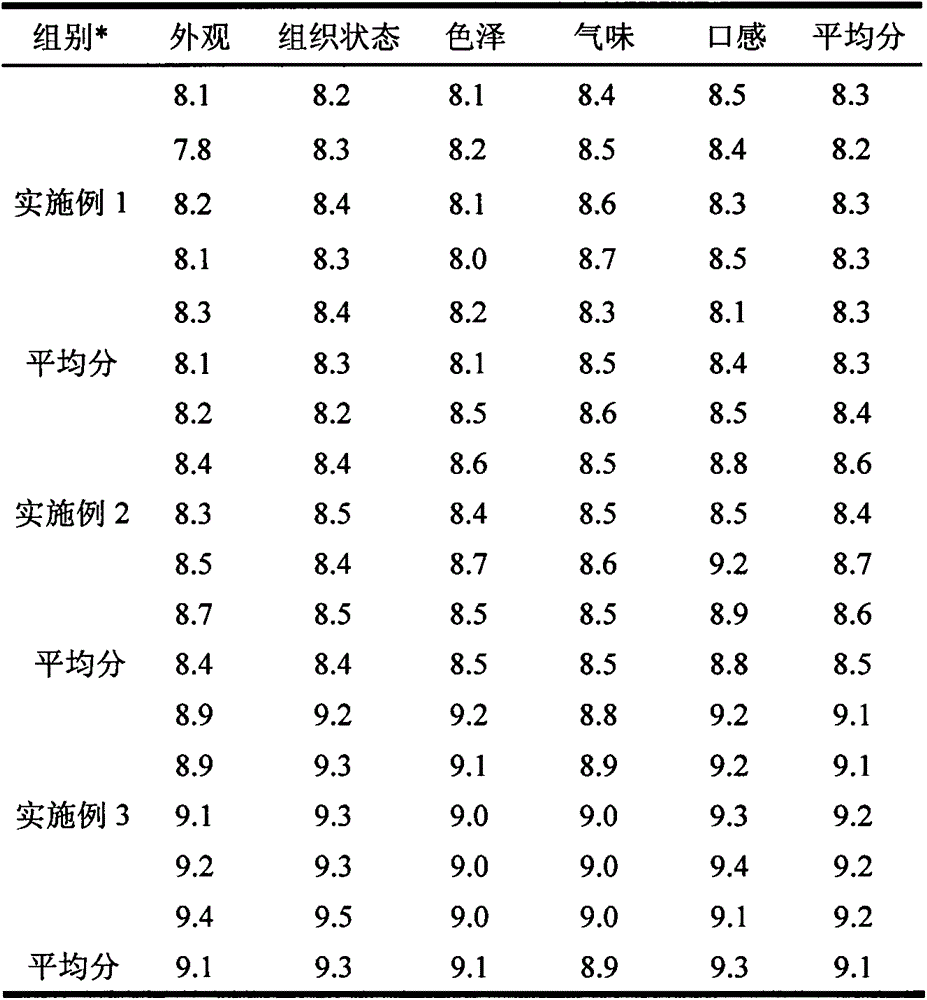

Examples

Embodiment 1

[0020] Take 20kg of fresh pork and cut it into 1.8-2.3cm 3 Add 0.6kg of salt and 0.4kg of glucose, and marinate at 0-4°C for 24 hours; add 30kg of thawed surimi to the marinated pork, then add 0.05kg of monosodium glutamate, 1kg of rice wine, and ginger juice 0.5kg, chili powder 0.25kg, Chinese prickly ash powder 0.2kg and polyphosphate 0.15kg, cut and mix into minced meat, the temperature of chopping and mixing is controlled below 15°C; put the chopped and mixed minced meat in a vacuum mixer, and then Add 0.5 kg of mixed starter (Lactobacillus plantarum: Staphylococcus xylosus=1:2), stir while vacuuming, and stir for 5 minutes; pour the mixed minced meat into pig casings, and the temperature of the meat filling should be at 5 Between ~10°C, the sausage is tied at 100-150g per root; the filled sausage is fermented in a fermentation room at a temperature of 30°C and a RH of 85%. After 24 hours of fermentation, the pH of the sausage is 4.5-4.9. The fermented sausages were dried...

Embodiment 2

[0022] Take 20kg of fresh pork and cut it into 1.8-2.3cm 3 Add 0.6kg of salt and 0.4kg of glucose, and marinate at 0-4°C for 24 hours; add 30kg of thawed surimi to the marinated pork, then add 0.075kg of monosodium glutamate, 1.25kg of rice wine, and ginger Juice 0.75kg, chili powder 0.35kg, Chinese prickly ash powder 0.3kg and polyphosphate 0.2kg, chop and mix into mince, the temperature of chopping and mixing is controlled below 15°C; put the chopped and mixed minced meat in a vacuum mixer, Add 0.5 kg of mixed starter (Pediococcus pentosaceae: Staphylococcus xylosus = 1:2), stir while vacuuming, and stir for 5 minutes; pour the mixed minced meat into pig casings, and the temperature of the meat filling should be Between 5-10°C, the sausage is tied at 100-150g per root; put the stuffed sausage in the fermentation room for fermentation, the temperature is 30°C, the RH is 85%, after 24 hours of fermentation, the pH of the sausage is 4.5- 4.9. The fermented sausages were dried...

Embodiment 3

[0024] Take 20kg of fresh pork and cut it into 1.8-2.3cm 3 Add 0.6kg of salt and 0.4kg of glucose, and marinate at 0-4°C for 24 hours; add 30kg of thawed surimi to the marinated pork, then add 0.06kg of monosodium glutamate, 1.1kg of rice wine, and ginger Juice 0.6kg, chili powder 0.3kg, Chinese prickly ash powder 0.25kg and polyphosphate 0.18kg, insert 0.5kg mixed fermentation agent (lactobacillus plantarum: staphylococcus xylosus=1: 2) then, chop and mix evenly, chop The mixing temperature is controlled below 15°C; pour the chopped fish and pork into pig casings, the temperature of the meat filling should be between 5 and 10°C during filling, and the sausage should be tied at 100-150g per piece; The sausages were fermented in a fermentation room at a temperature of 30° C. and a RH of 85%. After 24 hours of fermentation, the pH of the sausages was 4.5-4.9. The mature fermented sausages were dried at 55°C for 20 minutes, cooled to room temperature naturally, vacuum-packed, st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com