Method for preparing fish scale gelatin plasma substitute injection

A fish scale gelatin and injection technology, which is applied in blood diseases, pharmaceutical formulations, extracellular fluid diseases, etc., can solve the problem of high cost of raw materials, and achieve the effects of high cross-linking degree, accurate control of reaction conditions, and improved filtration speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

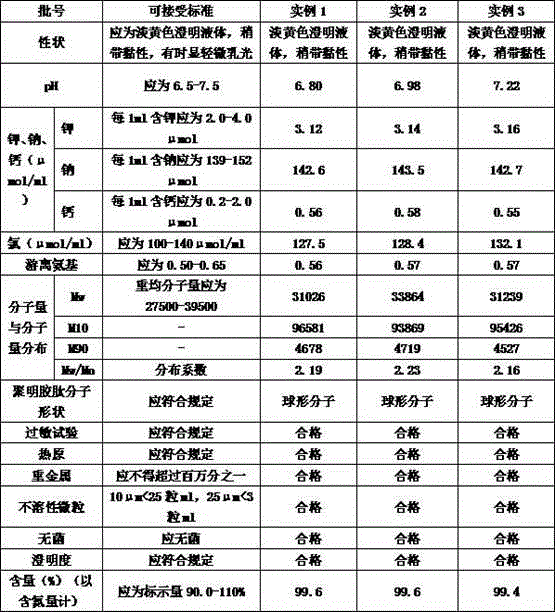

Examples

example 1

[0034] 1. Degradation of fish scale gelatin: Dissolve 210g of fish scale gelatin (32g based on nitrogen content) with 1500ml of water for injection heated to 90°C, adjust the pH value of the fish scale gelatin solution to 5.5 with hydrochloric acid or sodium hydroxide solution, and dissolve the fish scale gelatin Heat the gelatin solution to 115°C, keep warm and monitor the relative viscosity of the fish scale gelatin solution, when the relative viscosity reaches 1.7, stop heating immediately, and cool to 40°C to obtain a fish scale gelatin degradation solution;

[0035] 2. Cross-linking modification: adjust the fish scale gelatin degradation solution with hydrochloric acid or sodium hydroxide solution to make the pH value to 8.5, keep the temperature at 40°C, add 1.6g of succinic anhydride, stir continuously, and cross-link for 2 hours;

[0036] 3. Add electrolyte: add 2500ml of water for injection to the fish scale gelatin cross-linking solution, add 1.1g of potassium chlorid...

example 2

[0041] 1. Degradation of fish scale gelatin: Dissolve 220g of fish scale gelatin (32g in terms of nitrogen content) in 2000ml of water for injection heated to 80°C, adjust the pH value of the fish scale gelatin solution to 6 with hydrochloric acid or sodium hydroxide solution, and dissolve the fish scale gelatin Heat the gelatin solution to 120°C, keep warm and monitor the relative viscosity of the fish scale gelatin solution, when the relative viscosity reaches 1.8, stop heating immediately, and cool to 35°C to obtain a fish scale gelatin degradation solution;

[0042] 2. Cross-linking modification: adjust the fish scale gelatin degradation solution with hydrochloric acid or sodium hydroxide solution to make the pH value to 9, keep the temperature at 35°C, add 2.52g of succinic anhydride, stir continuously, and cross-link for 2 hours;

[0043] 3. Add electrolyte: Add 2500ml of water for injection to the fish scale gelatin cross-linking solution, add 1.1g of potassium chloride,...

example 3

[0048] 1. Degradation of fish scale gelatin: Dissolve 205g of fish scale gelatin (32g in terms of nitrogen content) in 2500ml of water for injection heated to 70°C, adjust the pH value of the fish scale gelatin solution to 6.5 with hydrochloric acid or sodium hydroxide solution, and dissolve the fish scale gelatin Heat the gelatin solution to 125°C, keep warm and monitor the relative viscosity of the fish scale gelatin solution, when the relative viscosity reaches 1.9, stop heating immediately, and cool to 30°C to obtain a fish scale gelatin degradation solution;

[0049] 2. Cross-linking modification: adjust the fish scale gelatin degradation solution with hydrochloric acid or sodium hydroxide solution to make the pH value to 9.5, keep the temperature at 30°C, add 1.95g of succinic anhydride, stir continuously, and cross-link for 2 hours;

[0050] 3. Add electrolyte: Add 2000ml of water for injection to the fish scale gelatin cross-linking solution, add 1.1g of potassium chlor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com