High-stain-resistance elastic and round-shaped broom-finish emulsion paint and preparation method thereof

A round shape, latex paint technology, applied in latex paint, biocide-containing paint, anti-fouling/underwater paint, etc., can solve the problems of complicated preparation methods and difficult defoaming, and achieve excellent color development and pinhole The effect of less and easy mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

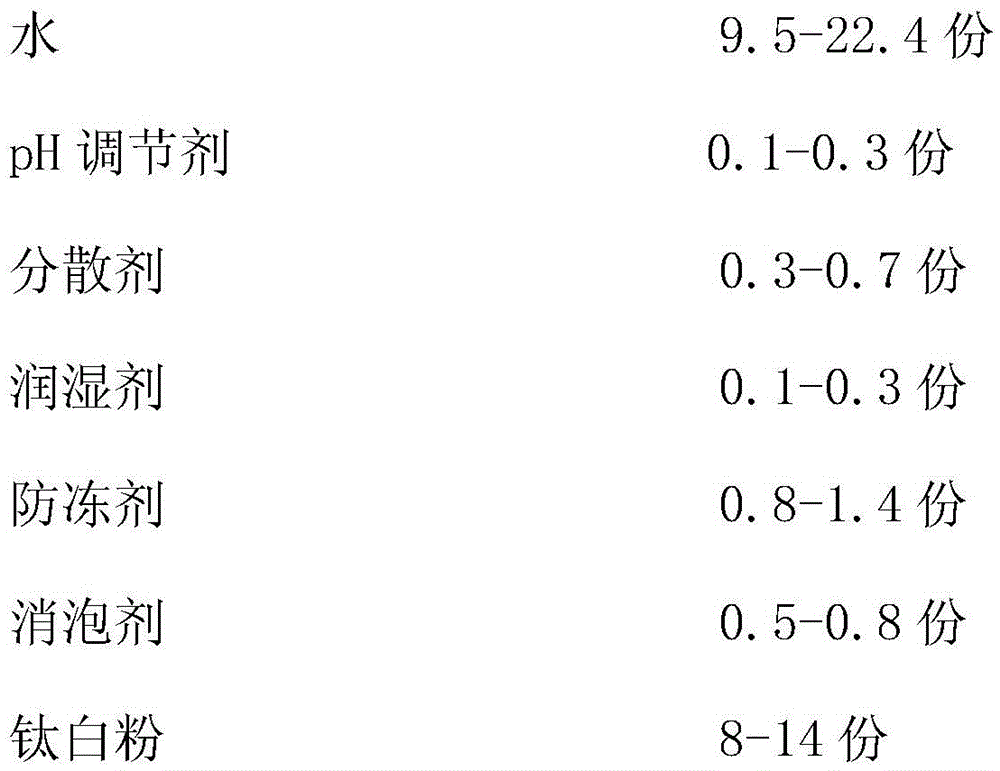

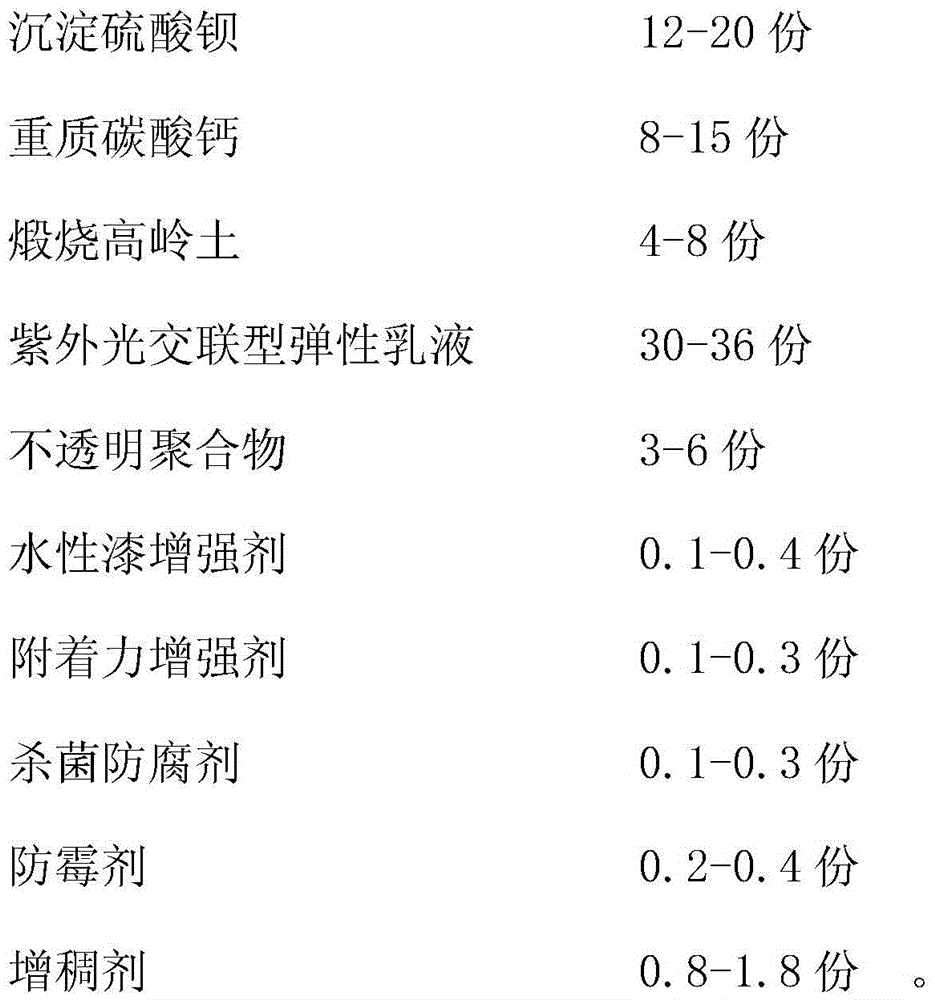

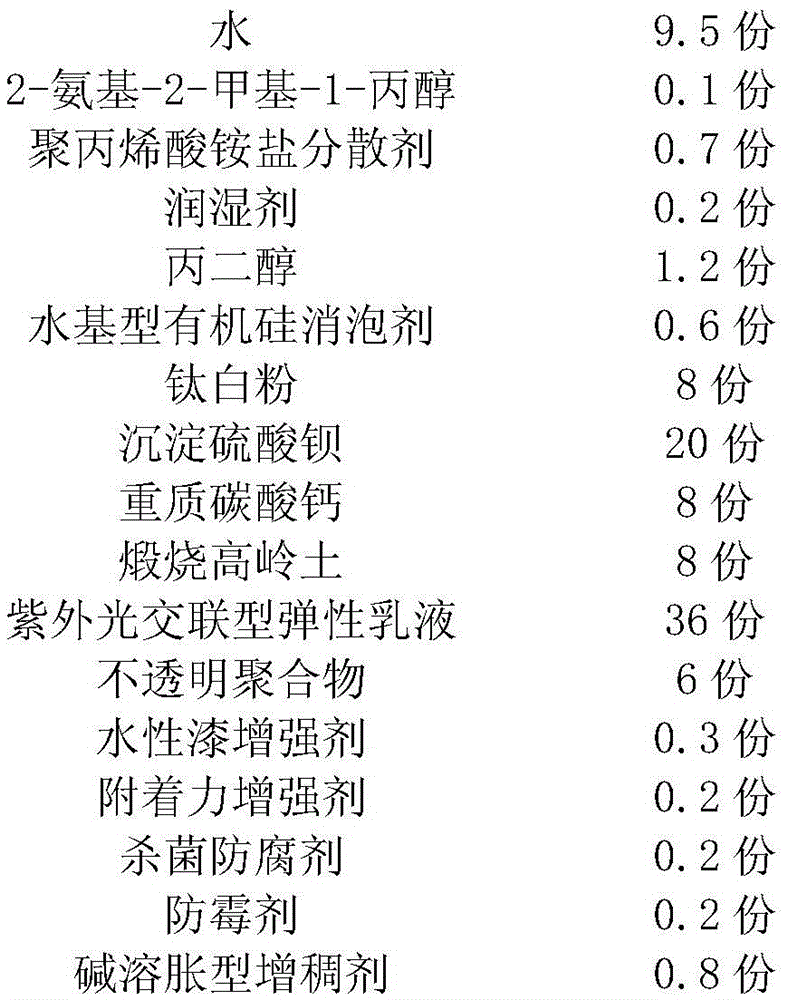

[0048] A highly stain-resistant elastic round-shaped brushed latex paint, which is formulated from the following components in parts by weight:

[0049]

[0050] The preparation method of the highly stain-resistant elastic circular brushed latex paint comprises the following steps in sequence:

[0051] ①At the speed of 700rpm, add 2-amino-2-methyl-1-propanol, polyacrylate ammonium salt dispersant, wetting agent, propylene glycol, water-based silicone defoamer, titanium dioxide, precipitation Barium sulfate, heavy calcium carbonate and calcined kaolin were mixed and dispersed for 18 minutes, wherein the amount of the water-based silicone defoamer was 1 / 2 of its own total weight;

[0052] ②At the speed of 750rpm, add UV cross-linked elastic emulsion, opaque polymer, remaining water-based silicone defoamer, water-based paint enhancer, adhesion enhancer, Bactericidal preservatives, antifungal agents, and disperse for 6 minutes;

[0053] ③At the speed of 1100rpm, slowly add th...

Embodiment 2

[0055] A highly stain-resistant elastic round-shaped brushed latex paint, which is formulated from the following components in parts by weight:

[0056]

[0057]The preparation method of the highly stain-resistant elastic circular brushed latex paint comprises the following steps in sequence:

[0058] ①At the speed of 600rpm, add 2-amino-2-methyl-1-propanol, ammonium polyacrylate dispersant, wetting agent, propylene glycol, mineral oil defoamer, titanium dioxide, precipitated barium sulfate to the water in sequence , heavy calcium carbonate and calcined kaolin were mixed and dispersed for 20 minutes, wherein the amount of the mineral oil defoamer was 50% of its own total weight;

[0059] ②At a speed of 600rpm, add UV cross-linked elastic emulsion, opaque polymer, remaining mineral oil defoamer, water-based paint enhancer, adhesion enhancer, bactericidal and antiseptic to the mixture prepared in step ① in sequence agent, antifungal agent, and disperse for 8 minutes;

[006...

Embodiment 3

[0062] A highly stain-resistant elastic round-shaped brushed latex paint, which is formulated from the following components in parts by weight:

[0063]

[0064] The preparation method of the highly stain-resistant elastic circular brushed latex paint comprises the following steps in sequence:

[0065] ①At the speed of 800rpm, add 2-amino-2-methyl-1-propanol, polycarboxylate sodium salt dispersant, wetting agent, ethylene glycol, water-based silicone defoamer, titanium White powder, precipitated barium sulfate, heavy calcium carbonate and calcined kaolin were mixed and dispersed for 15 minutes, wherein the amount of the water-based silicone defoamer was 60% of its total weight;

[0066] ②At the speed of 800rpm, add UV-crosslinked elastic emulsion, opaque polymer, remaining water-based silicone defoamer, water-based paint enhancer, adhesion enhancer, Bactericidal preservatives, antifungal agents, and disperse for 5 minutes;

[0067] ③At the speed of 1200rpm, slowly add the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com