Method for separating oil and sands by adopting mixed solvent

A technology for mixing solvent and oil sand, applied in the field of separating bitumen in oil sand, can solve the problems of inability to implement industrialized implementation, difficult to obtain solvent, and high economic cost, and achieve the effect of saving intermediate operation cost, convenient operation and continuous operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

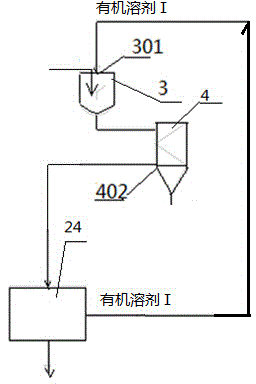

[0037] use figure 1 The process uses solvents to separate oil sands, and the weight content of bitumen in oil sands is 20%

[0038] 5 kg of oil sand particles crushed to a size of 20mm by the high-temperature water crushing and desander of the spiral drum are sent to the primary stirring tank 3 and mixed with the organic solvent I at 25°C, stirred for 10 minutes, and then sent to the primary suspension separator 4. liquid-solid separation;

[0039] The organic solvent I is a mixture of n-octane and isobutyraldehyde, and the volume ratio is n-octane:isobutyraldehyde=1:5;

[0040] The mass ratio of organic solvent I to oil sand is 2:1;

[0041] The separated extraction phase is sent to the subsequent refining process 24, and the asphalt and organic solvent I are separated, and the organic solvent I is recycled;

[0042] The extraction rate of the obtained oil sand bitumen is 100%, and the solvent recovery rate is 100%.

Embodiment 2

[0044] use figure 1 The device uses a solvent to separate oil sands, and the weight content of asphalt in oil sands is 30%

[0045] 5kg of oil sand particles crushed to a size of 20mm by the high-temperature water crushing and desander of the spiral drum are sent to the primary stirring tank 3 and mixed with the organic solvent I at 20°C, stirred and extracted for 15 minutes, and then sent to the primary suspension separator 4 , for liquid-solid separation;

[0046] The organic solvent I is a mixture of n-octane and isobutyraldehyde, and the volume ratio is n-octane:isobutyraldehyde=1:8;

[0047] The mass ratio of organic solvent I to oil sand is 3:1;

[0048] The separated extraction phase is sent to the subsequent refining process 24, and the asphalt and organic solvent I are separated, and the organic solvent I is recycled;

[0049] The separated residual coarse particle solid is sent to the spiral dryer 7 for desolvation treatment;

[0050] The extraction rate of the o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com