Fabric fluffing composition and application thereof to cellulose fiber fabric fluffing process

A cellulose fiber and composition technology, which is applied to a fabric raising composition and its application field in the raising process of cellulose fiber fabrics, can solve the problems of affecting the home environment, respiratory diseases, abrasion and the like, and solves the problem of easy hair loss. , Soft hand feeling, good skin-friendly effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

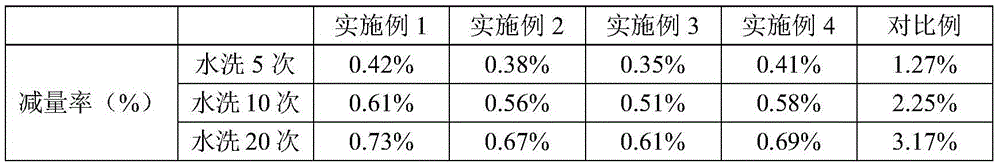

Examples

Embodiment 1

[0022] Fabric fluffing composition comprises in concentration: cellulose endoglucanase 10g / L, the consumption of nonionic surfactant alkylphenol polyoxyethylene ether 4g / L, fatty alcohol polyoxyethylene ether is 8g / L L, salt 0.1g / L, preservative 1g / L, acetic acid 6g / L, citric acid 5g / L, solvent is water, free chlorine is not contained in water.

[0023] The application method of the above-mentioned fabric raising composition in the raising process of cellulose fiber fabrics:

[0024] Specifications: 106” / Tencel 32s*Cotton 21s / 133*603 / 1 Twill

[0025] (1) Pretreatment

[0026] One front and one reverse singeing, rolling and desizing enzyme working solution and stacking for 8 hours; the desizing semi-finished product is subjected to water washing and oxygen bleaching process, in which the amount of hydrogen peroxide is 2g / L, and the oxygen bleaching time is 30-40min; tenter whitening;

[0027] (2) Sanding

[0028] The number of sand skins is 320 mesh, the speed of the sand sk...

Embodiment 2

[0033] Fabric fluffing composition comprises in concentration: cellulose endoglucanase 20g / L, the consumption of nonionic surfactant alkylphenol polyoxyethylene ether 8g / L, fatty alcohol polyoxyethylene ether is 12g / L L, salt 1.2g / L, preservative 1.5g / L, formic acid 6g / L, oxalic acid 5g / L, the solvent is water, and the water does not contain free chlorine.

[0034] The application method of the above-mentioned fabric raising composition in the raising process of cellulose fiber fabrics:

[0035] Specifications: 106” / cotton 32s*tencel 21s / 133*604 / 1 herringbone twill

[0036] (1) Pretreatment

[0037] One front and one reverse singeing, rolling desizing enzyme working solution and stacking for 8 hours; the desizing semi-finished products are washed and oxygen bleached, in which the amount of hydrogen peroxide is 2g / L, and the oxygen bleaching time is 30-40min; tenter whitening;

[0038](2) Sanding

[0039] The number of sand skins is 320 mesh, the speed of the sand skin rolle...

Embodiment 3

[0044] Fabric fluffing composition comprises in concentration: cellulose endoglucanase 30g / L, the consumption of nonionic surfactant alkylphenol polyoxyethylene ether 10g / L, fatty alcohol polyoxyethylene ether is 15g / L L, salt 3g / L, preservative 2g / L, acetic acid 4g / L, citric acid 7g / L, the solvent is water, and the water does not contain free chlorine.

[0045] The application method of the above-mentioned fabric raising composition in the raising process of cellulose fiber fabrics:

[0046] Specifications: 106” / Tencel 21s* Cotton 21s / 108*583 / 1 Twill

[0047] (1) Pretreatment

[0048] One front and one reverse singeing, rolling and desizing enzyme working solution and stacking for 8 hours; the desizing semi-finished product is subjected to water washing and oxygen bleaching process, in which the amount of hydrogen peroxide is 2g / L, and the oxygen bleaching time is 30-40min; tenter whitening;

[0049] (2) Sanding

[0050] The mesh number of the sand surface is 320 mesh, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com