Cabin of conical rotary body structure and manufacturing method of cabin

The technology of a rotary body and a cone body is applied to the cabin body of the conical rotary body structure and its production field, which can solve the problems of less use of the cabin body, poor shape and dimension accuracy, out-of-tolerance, etc., so as to improve the quality and quality consistency, The effect of reducing structural weight and reducing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0034] The fibers used in the cabin body include glass fiber, carbon fiber, aramid fiber, ultra-high molecular weight polyethylene fiber, basalt fiber, etc., and the resin includes epoxy, polyester, and the like.

[0035] Implementation steps:

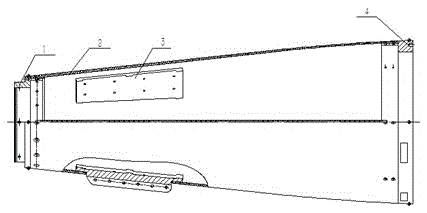

[0036] (1) Carry out composite material cabin design according to the finished product dimensions, and determine the structural dimensions of the two-end joint frame and the fiber-wound composite material cone.

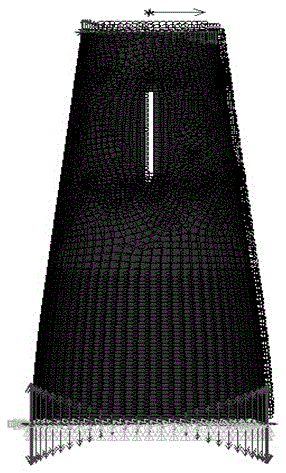

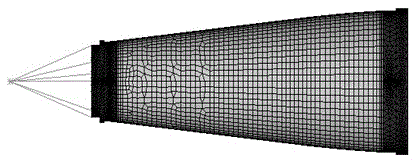

[0037] (2) Carry out the finite element analysis and calculation of the composite material cone to determine the structure of the cone

[0038] The composite material cone is the key to the load-bearing design of the cabin body. Due to the large difference in the size of the two ports, the winding molding process is adopted, and the result must be a structure with variable section (that is, variable thickness) and variable winding angle, which is different from ordinary composite materials. The structure adopts the single-lay...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com