Lithium titanate negative electrode plate and preparation method thereof

A technology of negative pole piece and lithium titanate, which is applied to battery electrodes, electrode carriers/current collectors, structural parts, etc., can solve the problems of limited improvement of battery performance and poor coating performance of lithium titanate negative pole piece, etc. Coating uniformity, improved bonding effect, overall performance improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

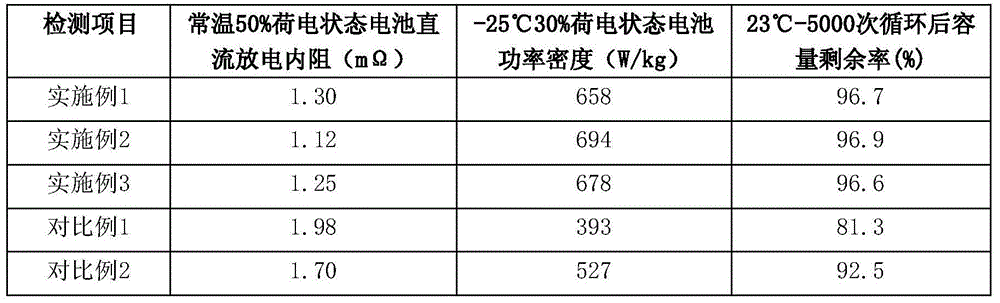

Examples

Embodiment 1

[0024] A lithium titanate negative electrode sheet, comprising a negative electrode current collector and a negative electrode material coated on the surface of the negative electrode current collector, the negative electrode current collector is a carbon-coated aluminum foil with double-sided carbon-coated layers, and the thickness of one side of the carbon-coated aluminum foil is carbon-coated is 1.5 μm, the negative electrode material is composed of the following components by mass percentage: 2% conductive agent, 8% binder, 90% lithium titanate, and the compacted density of the negative electrode material is 2g / cm 3 , wherein the conductive agent is one or more of conductive carbon black, carbon nanotubes, graphite flakes, and vapor-phase grown carbon fibers, and the binder is polyvinylidene fluoride, polyamide or polyacrylic acid.

[0025] The lithium titanate negative electrode sheet is prepared by the following method:

[0026] (1) After weighing lithium titanate, condu...

Embodiment 2

[0030] A lithium titanate negative electrode sheet, comprising a negative electrode current collector and a negative electrode material coated on the surface of the negative electrode current collector, the negative electrode current collector is a carbon-coated aluminum foil with double-sided carbon-coated layers, and the thickness of one side of the carbon-coated aluminum foil is carbon-coated The negative electrode material is composed of the following components in mass percentage: 7% conductive agent, 6% binder, 87% lithium titanate, and the compacted density of the negative electrode material is 2.1g / cm 3 , wherein the conductive agent is one or more of conductive carbon black, carbon nanotubes, graphite flakes, and vapor-phase grown carbon fibers, and the binder is polyvinylidene fluoride, polyamide or polyacrylic acid.

[0031] The lithium titanate negative electrode sheet is prepared by the following method:

[0032] (1) After weighing lithium titanate, conductive age...

Embodiment 3

[0036] A lithium titanate negative electrode sheet, comprising a negative electrode current collector and a negative electrode material coated on the surface of the negative electrode current collector, the negative electrode current collector is a carbon-coated aluminum foil with double-sided carbon-coated layers, and the thickness of one side of the carbon-coated aluminum foil is carbon-coated The negative electrode material is composed of the following components in mass percentage: 3% conductive agent, 3% binder, 94% lithium titanate, and the compacted density of the negative electrode material is 2.3g / cm 3 , wherein the conductive agent is one or more of conductive carbon black, carbon nanotubes, graphite flakes, and vapor-phase grown carbon fibers, and the binder is polyvinylidene fluoride, polyamide or polyacrylic acid.

[0037] The lithium titanate negative electrode sheet is prepared by the following method:

[0038] (1) After weighing lithium titanate, conductive age...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com