Industrial dangerous waste treating system and method

The technology of a treatment system and a treatment method is applied in the field of industrial hazardous waste treatment system, which can solve the problems of sludge industrial hazardous waste not being properly disposed of, and achieve the effects of reduced treatment cost, stable working state and large treatment capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

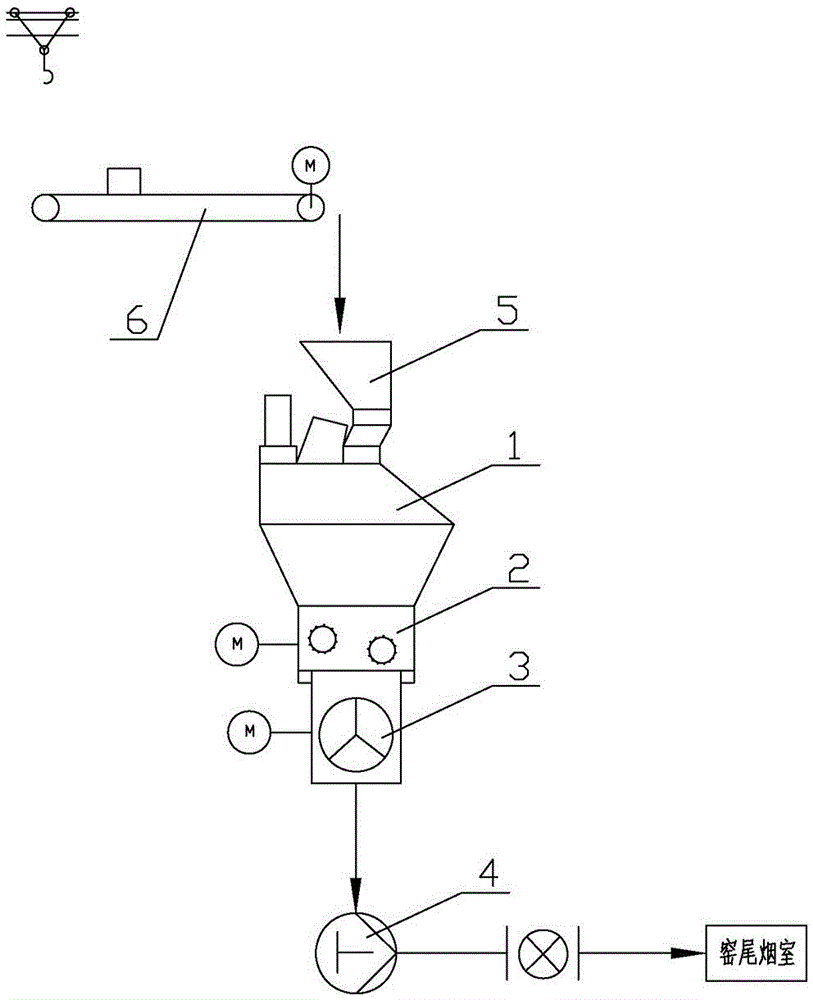

[0029] like figure 1 As shown, an industrial hazardous waste treatment system in this embodiment includes a feeder 1, a hazardous waste crushing device 2, a mixer 3 and a plunger pump 4 connected in sequence, wherein the output end of the plunger pump 4 is connected to an external cement kiln Tail smoke room.

[0030] The hazardous waste shredding device 2 is a rotary shearing shredder, which is filled with an inert gas (nitrogen in this example).

[0031] The input end of the feeder 1 is connected with a feeding hopper 5, and the input end of the feeding hopper 5 is provided with a hazardous waste conveyor belt 6.

[0032] A method for treating hazardous industrial waste, characterized in that it comprises the following steps:

[0033] A. Industrial hazardous waste is transported into the factory after being sealed and packaged by car, and first passes through the ground scale (using the original one) for preliminary measurement;

[0034] B. Transported to the hazardous wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com