Copper chloride corrosion device and method for printing roller

A corrosion device, copper chloride technology, applied in the preparation of printing surface, printing, etc., can solve the problems of serious side corrosion, difficult to control corrosion, uneven corrosion, etc., to reduce wastewater discharge, ensure stability, and solve uneven corrosion Uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

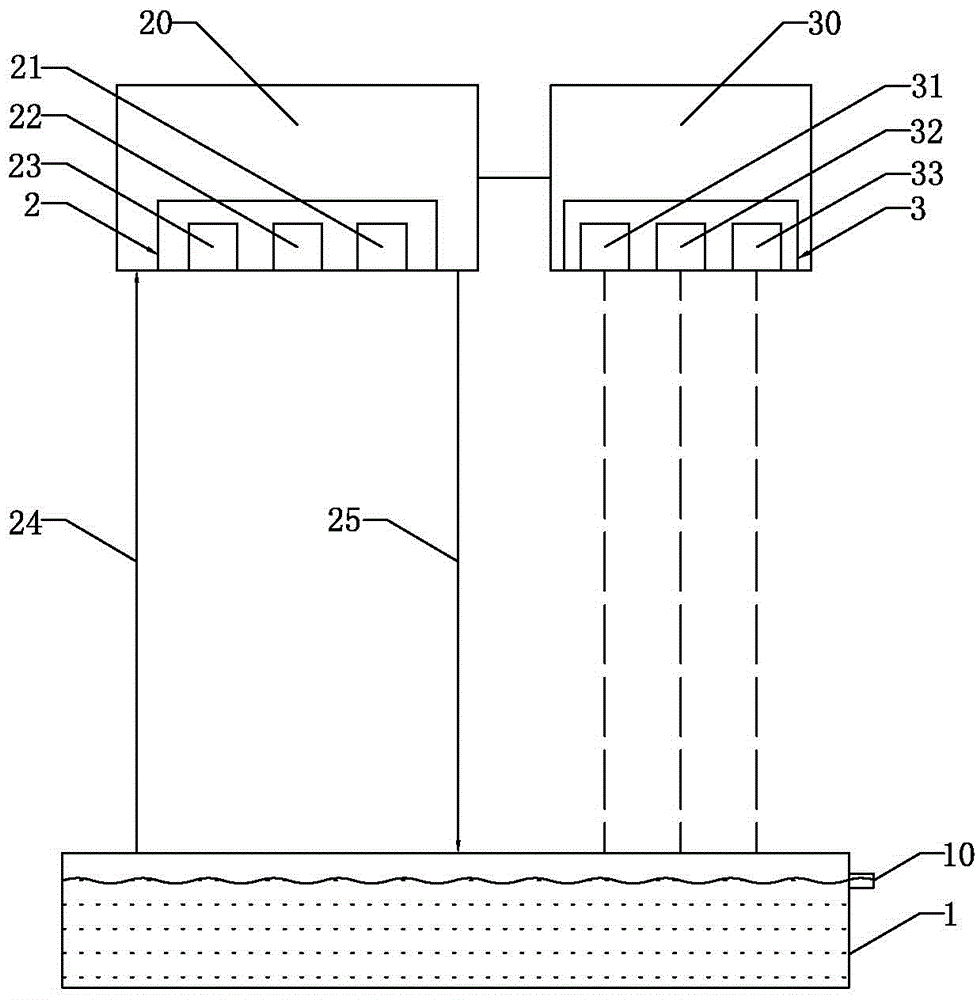

[0025] See figure 1 , a copper chloride corrosion device for plate rolls, comprising a corrosion solution tank 1 for containing the corrosion solution, a detection sensor 2 for detecting the concentration of each raw material in the corrosion solution, and an automatic sampling device for automatically adding each raw material 3. The detection sensor 2 is electrically connected to the automatic sample loading device 3 .

[0026] The detection sensor 2 includes a specific gravity sensor 21 for detecting the concentration of copper chloride in the corrosion solution, a hydrochloric acid sensor 22 for detecting the concentration of hydrochloric acid in the corrosion solution, and a hydrogen peroxide sensor for detecting the concentration of hydrogen peroxide in the corrosion solution twenty three.

[0027] The automatic sample adding device 3 includes an automatic water adding device 31 for adjusting the concentration of copper chloride, an automatic hydrochloric acid adding dev...

Embodiment 2

[0040] The difference between this embodiment and the above-mentioned embodiment 1 is:

[0041] In the step (2), the content of each raw material is respectively: copper ion 60g / L, hydrochloric acid 35g / L, hydrogen peroxide 28g / L.

[0042] When the volume of the corrosion solution tank 1 in the step (1) is 1000L, the amount of copper chloride in the step (2) is 162.2Kg, the amount of hydrochloric acid is 106.1L, and the amount of hydrogen peroxide is 93.3L.

[0043]The step (3) further includes: putting the engraved version roller into the corrosion solution tank 1, and corroding the visible copper layer on the version roller, the corrosion temperature is 25°C, and the corrosion time is 15s.

Embodiment 3

[0045] The difference between this embodiment and the above-mentioned embodiment 1 is:

[0046] In the step (2), the contents of each raw material are respectively: copper ion 62.5g / L, hydrochloric acid 38.3g / L, hydrogen peroxide 36g / L.

[0047] When the volume of the corrosion solution tank 1 in the step (1) is 1000L, the amount of copper chloride in the step (2) is 168.9Kg, the amount of hydrochloric acid is 116.1L, and the amount of hydrogen peroxide is 108.0L.

[0048] The step (3) further includes: putting the engraved version roller into the corrosion solution tank 1, and corroding the visible copper layer on the version roller, the corrosion temperature is 30°C, and the corrosion time is 12s.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com