C/zrc composite material based on liquid phase melt impregnation and its preparation method

A composite material and melt impregnation technology, which is applied in the field of preparation of ultra-high temperature thermal protection structural materials, can solve the problems of reducing the preparation cycle of composite materials, expensive precursors, and difficult preservation of precursors, etc., so as to shorten the preparation cycle and improve densification. Efficiency, the effect of improving the introduction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

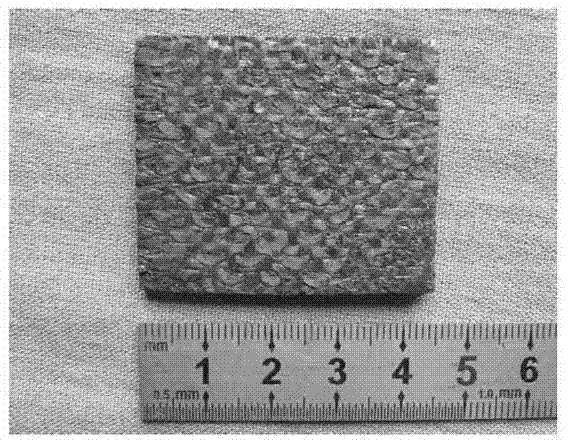

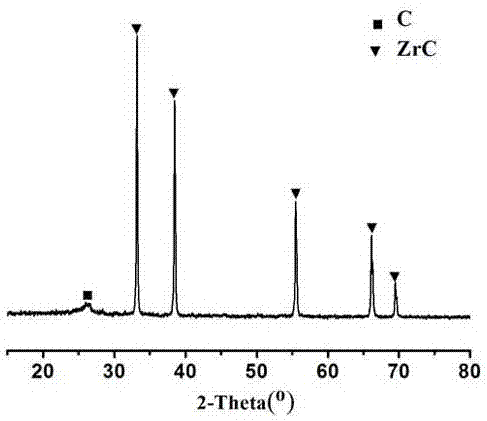

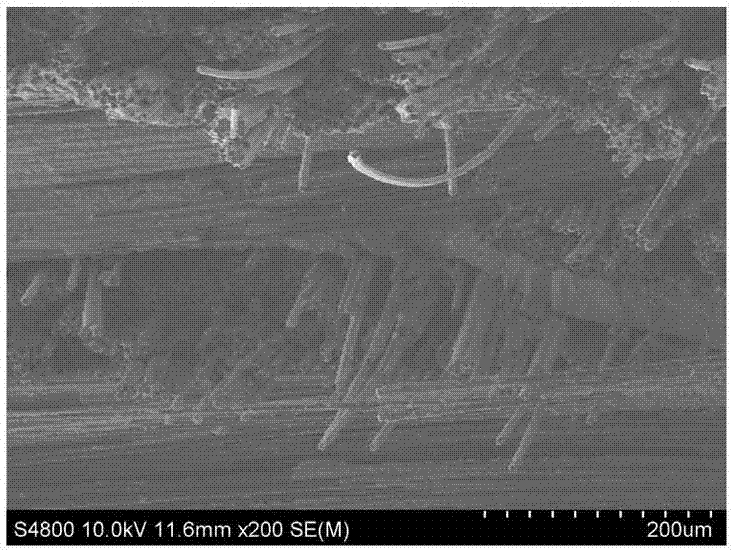

[0043] A C / ZrC composite material based on liquid phase melt impregnation of the present invention, the C / ZrC composite material uses three-dimensional punctured carbon fiber cloth as a reinforcement, uses zirconium carbide as a matrix, and zirconium carbide is impregnated on a carbon fiber preform through liquid phase melt impregnation . In the C / ZrC composite material, the volume fraction of three-dimensional punctured carbon fiber cloth is 40%, and the volume fraction of zirconium carbide is 33%. The density of the C / ZrC composite is 2.23g / cm 3 , The porosity is 9%.

[0044] A kind of preparation method of the C / ZrC composite material of above-mentioned present embodiment, comprises the following steps:

[0045] (1) Precursor preparation: Add zirconium acetylacetonate powder into a three-necked flask, feed nitrogen, heat to 200°C, and react with mechanical stirring for 0.5 hours. The white powder of zirconium acetylacetonate is melted into a brown liquid, and the brown li...

Embodiment 2

[0060] A C / ZrC composite material based on liquid phase melt impregnation of the present invention, the C / ZrC composite material uses three-dimensional punctured carbon fiber cloth as a reinforcement, uses zirconium carbide as a matrix, and zirconium carbide is impregnated on a carbon fiber preform through liquid phase melt impregnation . In the C / ZrC composite material, the volume fraction of three-dimensional punctured carbon fiber cloth is 40%, and the volume fraction of zirconium carbide is 36.7%. The density of the C / ZrC composite is 2.40g / cm 3 , The porosity is 8%.

[0061] A kind of preparation method of the C / ZrC composite material of above-mentioned present embodiment, comprises the following steps:

[0062] (1) Precursor preparation: Add zirconium acetylacetonate powder into a three-necked flask, feed nitrogen, heat to 200°C, and react with mechanical stirring for 0.5 hours. The white powder of zirconium acetylacetonate is melted into a brown liquid, and the brown ...

Embodiment 3

[0072] A C / ZrC composite material based on liquid phase melt impregnation of the present invention, the C / ZrC composite material uses three-dimensional punctured carbon fiber cloth as a reinforcement, uses zirconium carbide as a matrix, and zirconium carbide is impregnated on a carbon fiber preform through liquid phase melt impregnation . In the C / ZrC composite material, the volume fraction of three-dimensional punctured carbon fiber cloth is 40%, and the volume fraction of zirconium carbide is 44.4%. The density of the C / ZrC composite is 2.45g / cm 3 , The porosity is 8%.

[0073] A kind of preparation method of the C / ZrC composite material of above-mentioned present embodiment, comprises the following steps:

[0074] (1) Precursor preparation: Add zirconium acetylacetonate powder into a three-necked flask, feed nitrogen, heat to 190°C, and react with mechanical stirring for 0.5 hours. The white powder of zirconium acetylacetonate melts into a brown liquid. Pour out the brown...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com