Method for preparing alginic acid pore-sealing type sustained release ecological fertilizer

A technology of alginic acid and ecological fertilizer, which is applied in the direction of ammonium orthophosphate fertilizer, alkaline orthophosphate fertilizer, nitrogen fertilizer, etc., can solve the problems of residual pollutants and high cost of slow-release chemical fertilizers, and achieve optimized soil structure and natural pollution-free soil Micro-ecological, active effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

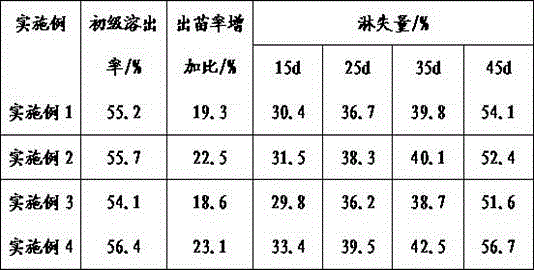

Examples

example 1

[0024] (1) Take 3 parts by weight of fly ash and 7 parts by weight of diatomaceous earth, together with the dispersant sodium silicate solution, add them to a low-speed mixer, stir and disperse for 1 hour at a temperature not higher than 30°C, and then add 50 Parts by weight of urea, 15 parts by weight of monoammonium phosphate and ethyl orthosilicate, continue to stir for 0.5h; the stirring speed is not greater than 40r / min;

[0025] (2) Dissolve 15 parts by weight of alginic acid in sodium hydroxide solution to prepare a sodium alginate solution, add 5 parts by weight of calcium carbonate powder, stir and mix at high speed for 10 minutes, and then add it to the mineral-adsorbed fertilizer solution obtained in step (1) , continue to stir for 5 to 10 minutes, and after standing for 60 minutes, obtain a fertilizer slurry sealed with gelled calcium alginate; the concentration of the prepared sodium alginate solution is 10 g / L, and the stirring speed is 300 r / min;

[0026] (3) Su...

example 2

[0028] (1) Take 5 parts of fly ash and 3 parts of attapulgite, add them to a low-speed mixer together with a dispersant, stir and disperse for 2 hours at a temperature not higher than 30°C, and then add 30 parts of urea and 20 parts of calcium phosphate parts, 15 parts of potassium sulfate and ethyl orthosilicate, continue to stir for 0.5h; wherein, the dispersant is sodium tripolyphosphate, the mass concentration is 15-25%, and the amount of dispersant added is 5 times of the mass of porous mineral powder ; The amount of tetraethyl orthosilicate is 1% of the fertilizer mass; the stirring speed is not greater than 40r / min;

[0029] (2) Dissolve the alginic acid in sodium hydroxide solution to prepare sodium alginate solution, add calcium carbonate powder, stir and mix at high speed for 20 minutes, then add the mineral fertilizer obtained in step (1), and continue stirring for 10 minutes , after standing for 30min, obtain the fertilizer slurry sealed by gelled calcium alginate;...

example 3

[0032] (1) Take 5 parts of bentonite and 5 parts of diatomaceous earth, add them to a low-speed mixer together with a dispersant, stir and disperse for 1.5 hours at a temperature not higher than 30°C, and then add 40 parts of monoammonium phosphate, disulfuric acid 35 parts of potassium hydrogen and ethyl orthosilicate, continue stirring for 0.5h; wherein, the dispersant is sodium hexametaphosphate, the mass concentration is 25%, and the amount of dispersant added is 10 times of the quality of porous mineral powder; The amount of ethyl ester added is 1% of the fertilizer mass; the stirring speed is not greater than 40r / min;

[0033] (2) Dissolve the alginic acid in a sodium hydroxide solution to prepare a sodium alginate solution, add calcium carbonate powder, stir and mix at a high speed for 15 minutes, then add the fertilizer solution obtained in step (1) by mineral adsorption, and continue stirring for 10 minutes , after standing for 60min, obtain the fertilizer slurry seal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com