A kind of preparation method of semi-flexible polyethersulfone/ketone anion exchange membrane

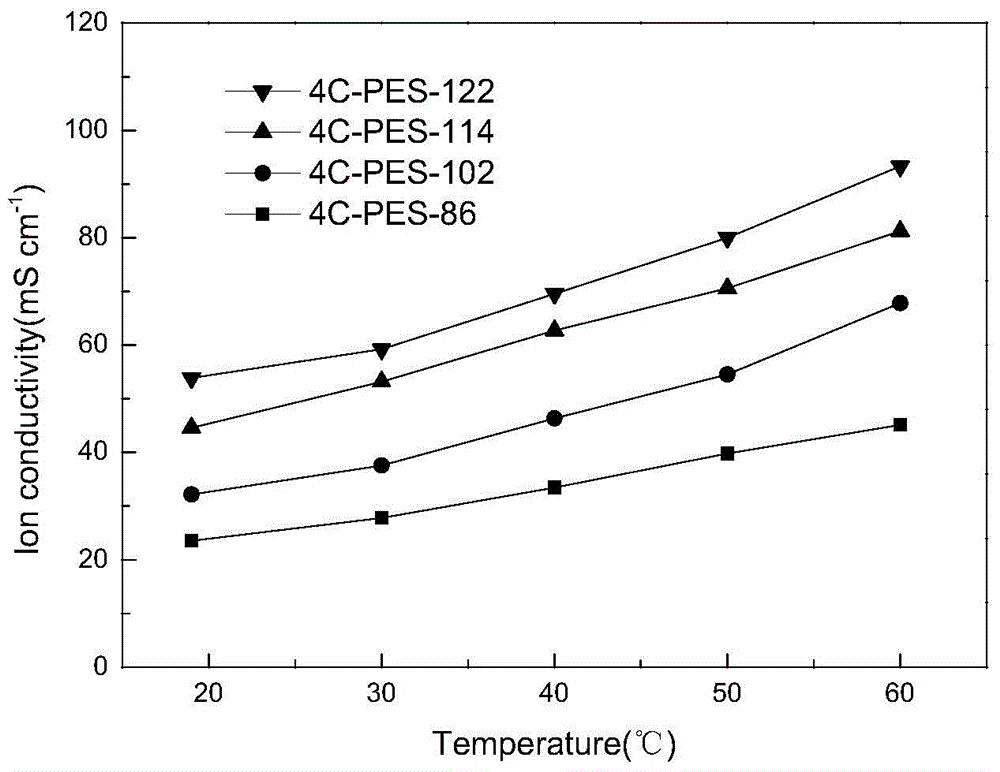

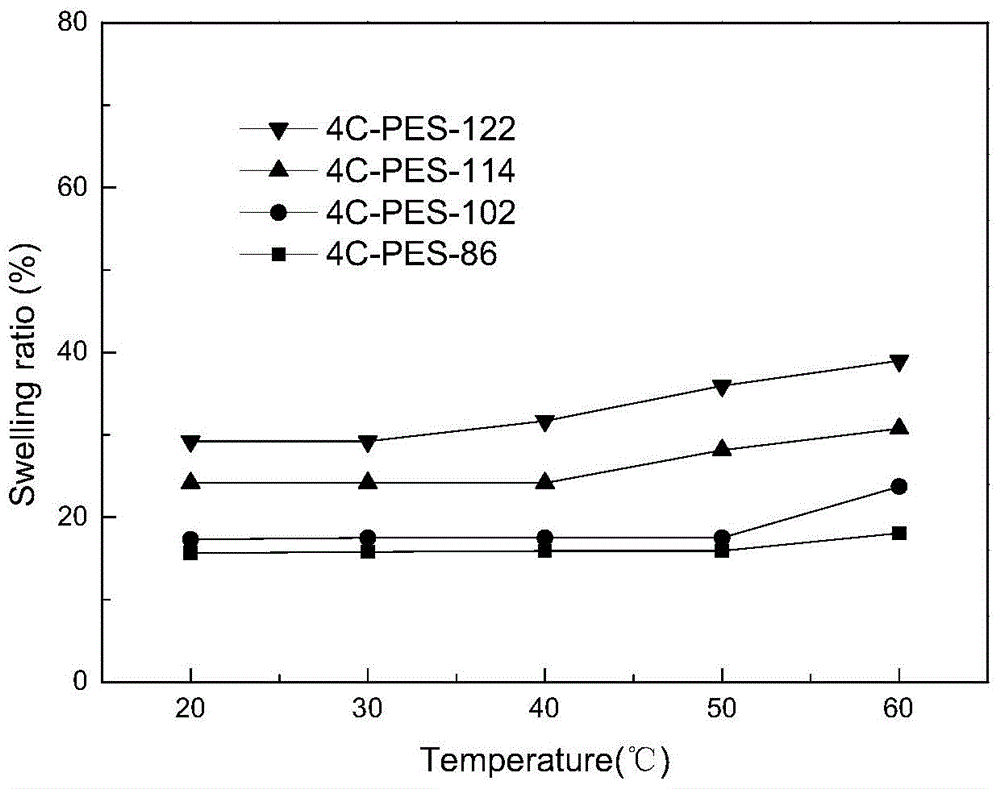

An anion exchange membrane and polyethersulfone technology, applied in electrical components, circuits, battery electrodes, etc., can solve the problems of inability to form ion channels, low ion conductivity, poor mechanical strength, etc., and achieve cheap and abundant raw materials and high ion conductivity The effect of simple steps and simple steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

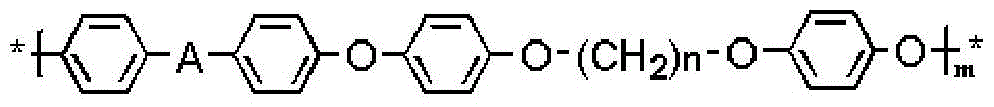

[0026] Preparation of 4C-PES polymer: Dissolve 0.05 mol of 1,4 dibromobutane and 0.5 mol of hydroquinone in 95% ethanol, heat to reflux, add 0.15 mol of KOH ethanol solution dropwise, react for 5 hours, and synthesize 4C flexible diphenol monomer, recrystallized to obtain pure material. In a three-neck flask equipped with a nitrogen inlet and outlet device and a Dean-Stark separator, add 2.5425g of 4,4-difluorodiphenylsulfone (10mmol), 2.7432g of 4C flexible diphenol monomer (10mmol), 30mL of DMSO, 2.7624 g of potassium carbonate (20 mmol) and 15 mL of toluene. Gradually raise the temperature to 140°C and reflux for 5 hours until the water is completely removed in the form of toluene / water azeotrope, then the temperature rises slowly to 165°C, and the temperature is kept constant for 15 hours. The reaction was complete and cooled to room temperature. The product was slowly poured into ice water, and a white fibrous polymer product was precipitated. Wash and soak the product...

Embodiment 2

[0032] Preparation of 6C-PES polymer:

[0033] Similar to the preparation method of 4C-PES in Example 1, the difference is that -CH 2 The number of - is 6. Dissolve 0.05 mol of 1,6-dibromohexane and 0.5 mol of hydroquinone in 95% ethanol, heat to reflux, drop 0.15 mol of KOH in ethanol solution, and react for 5 hours to synthesize 6C flexible diphenol mono body, recrystallized to obtain pure monomer. In a three-necked flask equipped with a nitrogen inlet and outlet device and a Dean-Stark separator, 2.5425g of 4,4-difluorodiphenylsulfone (10mmol), 3.0232g of 6C diphenol monomer (10mmol), 30mL of DMSO, 2. 7624 g of potassium carbonate (20 mmol) and 15 mL of toluene. Gradually raise the temperature to 140°C and reflux for 5 hours until the water is completely removed in the form of toluene / water azeotrope, then the temperature rises slowly to 165°C, and the temperature is kept constant for 15 hours. The reaction was complete and cooled to room temperature. The product was s...

Embodiment 3

[0035] Preparation of 8C-PES polymer:

[0036] Similar to the preparation method of 4C-PES in Example 1, the difference is that -CH 2 The number of - is 8. Dissolve 0.05 mol of 1,8-dibromooctane and 0.5 mol of hydroquinone in 95% ethanol, heat to reflux, add 0.15 mol of KOH in ethanol solution dropwise, and react for 5 hours to synthesize 8C flexible diphenol mono body, recrystallized to obtain pure monomer. In a three-neck flask equipped with a nitrogen inlet and outlet device and a Dean-Stark separator, 2.5425g of 4,4-difluorodiphenylsulfone (10mmol), 3.3232g of 8C diphenol monomer (10mmol), 30mL of DMSO, 2. 7624 g of potassium carbonate (20 mmol) and 15 mL of toluene. Gradually raise the temperature to 140°C and reflux for 5h until the water is completely removed in the form of toluene / water azeotrope, then the temperature rises slowly to 165°C, and the temperature is kept constant for 18h. The reaction was complete and cooled to room temperature. The product was slowl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com