ABS material with imitation marble decoration effect and preparation method thereof

An ABS material and decorative effect technology, applied in the field of ABS material and its preparation, can solve the problems of low impact resistance, insufficient weather resistance, poor wear resistance, etc., and achieve increased fluidity, good color and texture, and improved mechanical properties. and impact strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0023] In the above method for preparing the filled resin, the drying temperature of the polycarbonate resin in step 1) is 120-150° C., and the drying time is 3-6 hours.

[0024] In the preparation method of the above-mentioned filling resin, in parts by mass, the polycarbonate resin described in step 1) is 100 parts, the high temperature resistant colored pigment is 0.5 to 1 part, and the amount of silicone oil is 0.2 to 1 part; the high temperature resistant Coloring pigments are inorganic pigments, such as carbon black, titanium dioxide, iron oxide, etc. According to actual needs, inorganic pigments of different colors can be added to adjust the color of the filling resin.

[0025] In the above preparation method of filled resin, the conditions for extruding and granulating in step 2) are as follows: the twin-screw temperature of the twin-screw extruder is set in sections according to 250-280°C, and the head temperature is 230-250°C; The screw speed of the main machine is ...

Embodiment 1

[0043] Embodiment 1 Preparation of imitation marble decorative effect ABS material

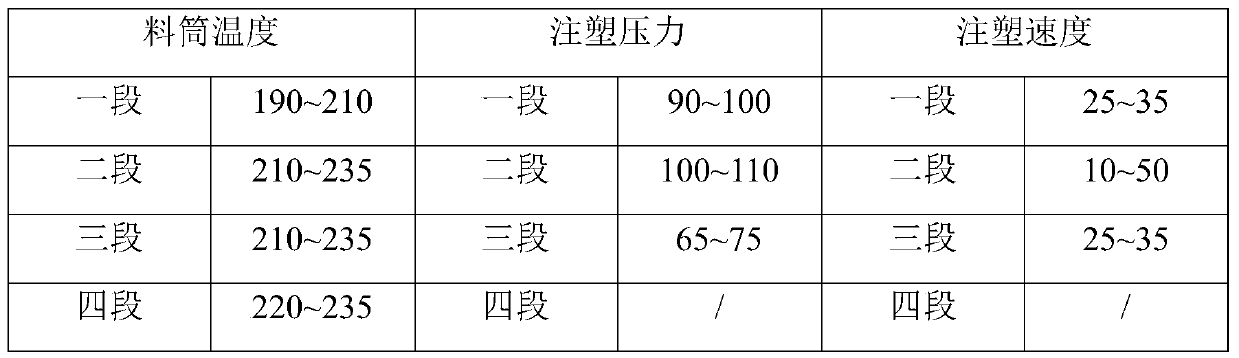

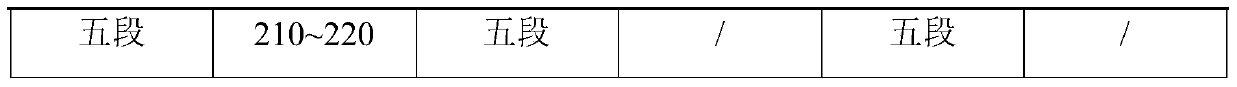

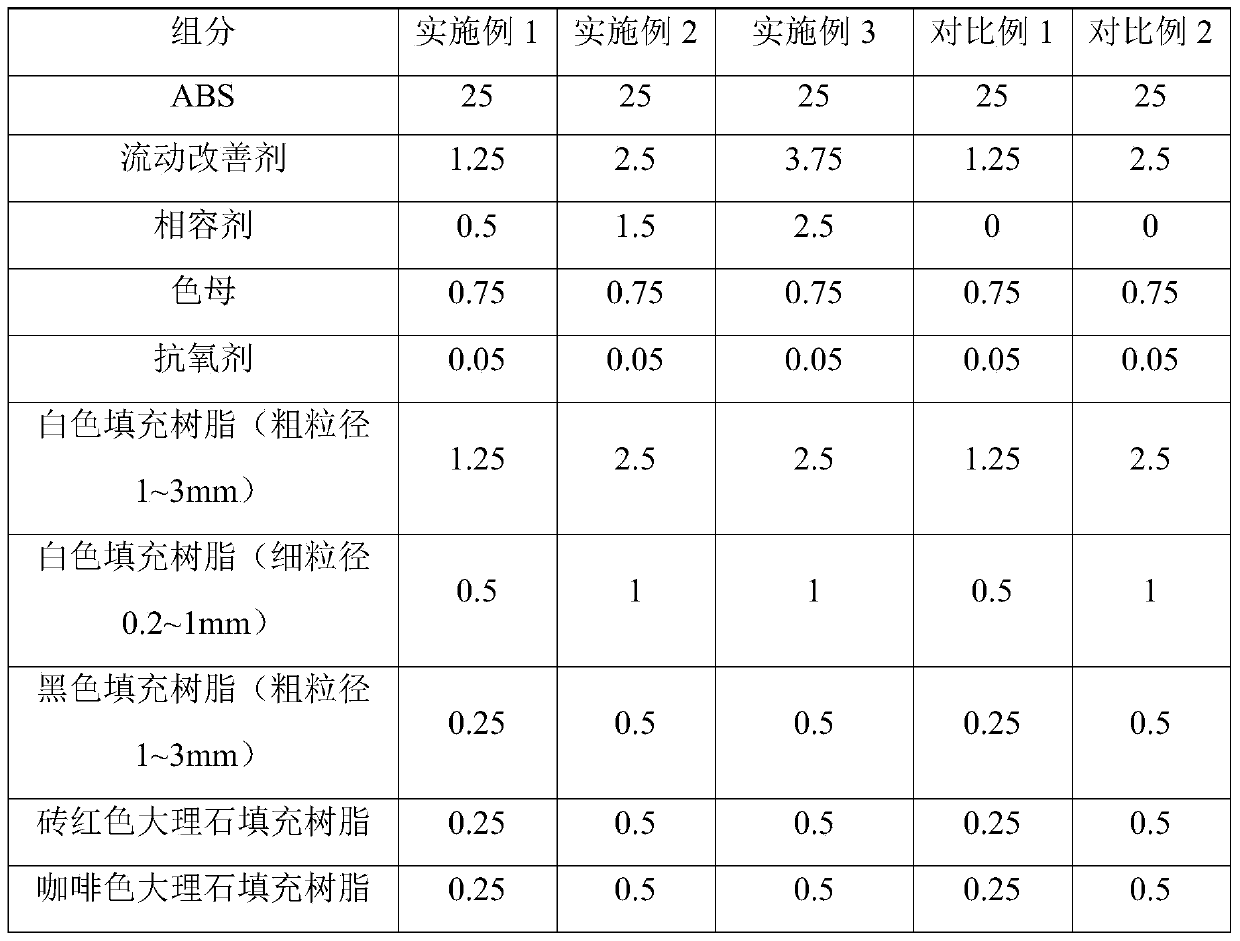

[0044] Various raw materials were weighed according to the raw material formula in Table 1.

[0045]a. Preparation of filled resin: 1) First dry polycarbonate resin at 120°C for 4 hours; mix 100 parts of dry polycarbonate resin and 1 part of silicone oil and stir for 2-10 minutes, then add high-temperature-resistant coloring pigment and stir for 3 minutes, and mix evenly to obtain Mixture. 2) Set the twin-screw temperature of the twin-screw extruder in sections according to 250-280°C, the head temperature is 230-250°C; the screw speed of the main engine is 30-35r / s, and the feeding speed is 25-30r / s; The underwater cutting and pulling method is adopted to make the diameter of the pellets be 0.5-3mm, and the resin is extruded and pelletized to obtain the filled resin. Wherein, the high-temperature-resistant coloring pigment added when preparing the white filling resin is titanium dioxide, 0.8...

Embodiment 2-5

[0048] Embodiment 2-5 Preparation of imitation marble decorative effect ABS material

[0049] The preparation method of Examples 2-5 is the same as that of Example 1, and the specific raw material ratio is shown in Table 1; the products of Examples 2-5 are tested according to the national standard, and the product performance data are shown in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| heat deflection temperature | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| heat deflection temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com