Environment-friendly PVC (polyvinyl chloride) decorative film and preparation method thereof

A decorative film, an environmentally friendly technology, applied in the field of environmentally friendly PVC decorative film and its preparation, can solve the problems of low thermal stability, poor adhesion of water-based ink, etc., achieve good thermal stability, good coloring power, and be conducive to industrial production Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

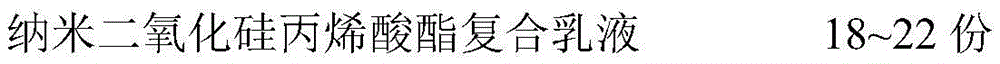

[0038] Water-based ink raw material components and preparation method thereof: the water-based ink is an inorganic nano-modified acrylate composite coating, and the raw material components are as follows in parts by weight:

[0039]

[0040] Water-based ink is prepared according to the following preparation method:

[0041] 1) Dispersion: Add the high solid content pigment filter cake directly to the mixed emulsion of nano-silica acrylate composite emulsion and self-crosslinking styrene-acrylic emulsion in parts by weight, then add defoamer, wetting and leveling agent, transfer Additives, industrial alcohol, and water are mixed evenly and then dispersed, the dispersion speed is controlled at 1100r / min, and the dispersion time is 20min;

[0042] 2) Preparation: Add an anionic surfactant in parts by weight of raw material components to the mixture obtained in step 1), then add a thickener to adjust the viscosity, control the dispersion speed to 700r / min, and the dispersion ti...

Embodiment 2

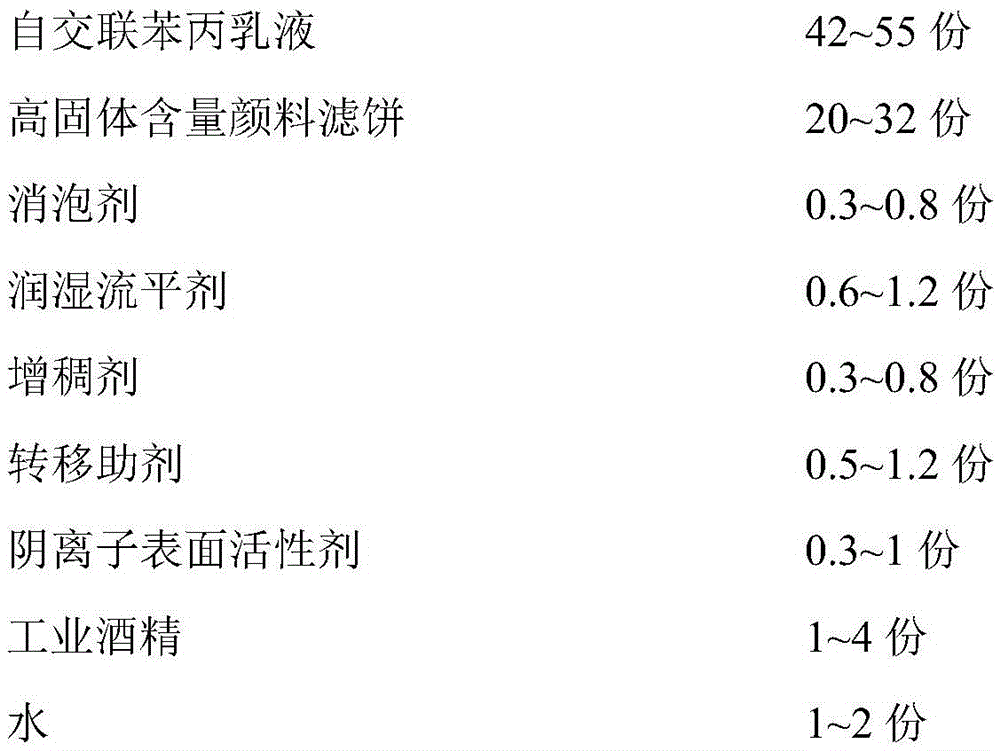

[0048] Water-based ink raw material components and preparation method thereof: the water-based ink is an inorganic nano-modified acrylate composite coating, and the raw material components are as follows in parts by weight:

[0049]

[0050] Water-based ink is prepared according to the following preparation method:

[0051]1) Dispersion: Add the high solid content pigment filter cake directly to the mixed emulsion of nano-silica acrylate composite emulsion and self-crosslinking styrene-acrylic emulsion in parts by weight, then add defoamer, wetting and leveling agent, transfer Additives, industrial alcohol, and water are mixed evenly and then dispersed, the dispersion speed is controlled at 1100r / min, and the dispersion time is 20min;

[0052] 2) Preparation: Add an anionic surfactant in parts by weight of raw material components to the mixture obtained in step 1), then add a thickener to adjust the viscosity, control the dispersion speed to 700r / min, and the dispersion tim...

Embodiment 3

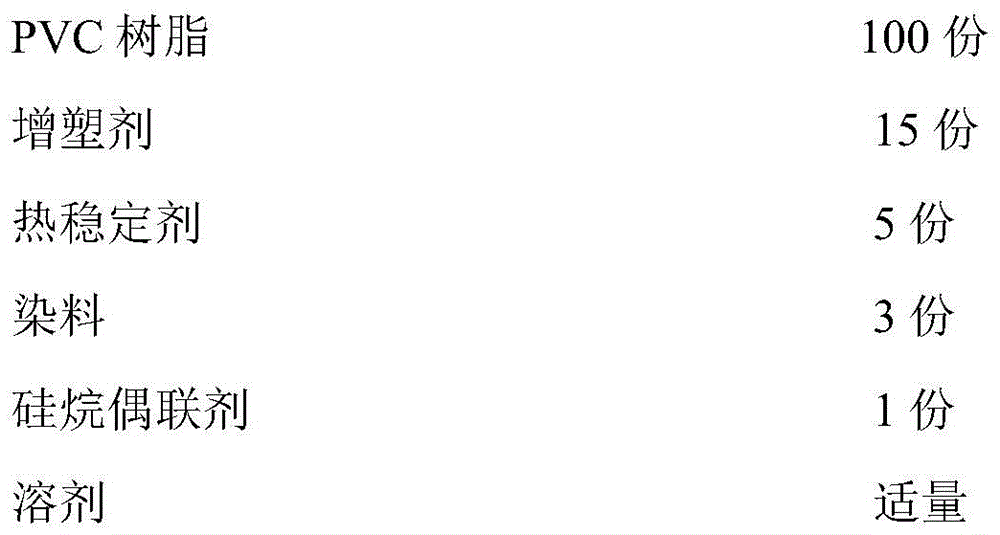

[0058] Water-based ink raw material components and preparation method thereof: the water-based ink is an inorganic nano-modified acrylate composite coating, and the raw material components are as follows in parts by weight:

[0059]

[0060] Water-based ink is prepared according to the following preparation method:

[0061] 1) Dispersion: Add the high solid content pigment filter cake directly to the mixed emulsion of nano-silica acrylate composite emulsion and self-crosslinking styrene-acrylic emulsion in parts by weight, then add defoamer, wetting and leveling agent, transfer Additives, industrial alcohol, and water are mixed evenly and then dispersed, the dispersion speed is controlled at 1100r / min, and the dispersion time is 20min;

[0062] 2) Preparation: Add an anionic surfactant in parts by weight of raw material components to the mixture obtained in step 1), then add a thickener to adjust the viscosity, control the dispersion speed to 700r / min, and the dispersion ti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com