Petroleum-degrading bactericide and preparation method thereof

A technology of oil-degrading bacteria and bacillus, applied in biochemical equipment and methods, methods based on microorganisms, bacteria, etc., can solve problems such as pollution, achieve environmental safety, convenient transportation and storage, and strong environmental adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

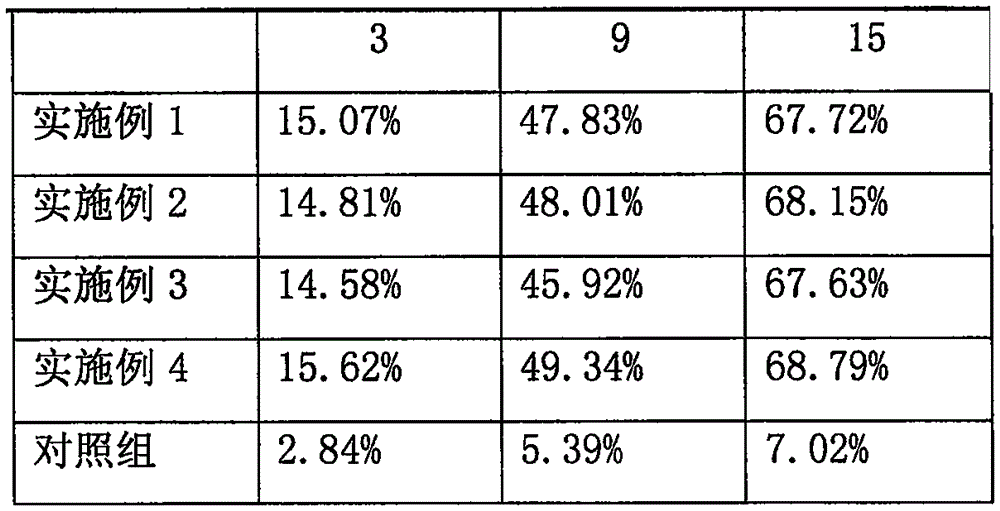

Examples

Embodiment 1

[0034] A preparation method of a petroleum degrading bacterial agent, comprising the following steps:

[0035] (1) The strains of Caulobacter ineruis, Candida parapsilosis, Brevibacterium phenol-resistant, Arthrobacter globosa, and Septoria salinii were expanded to a cell concentration of 10 9 ~10 10 cfu / g, mix Caulus ineruis, Candida parapsilosis, Brevibacterium phenol-resistant, Arthrobacter globosa and Septoria salinii according to the mass ratio of 3:2:2:1:1 to obtain the mixed bacteria kind;

[0036] (2) Autoclaving the liquid fermentation medium for 15-30min, in the aseptic operating table, inoculate the mixed strains obtained in step (1) into the sterilized liquid fermentation medium, the mixed strains and the liquid fermentation medium The weight ratio is 1:12, and the liquid fermentation medium inoculated with the mixed strains is placed in a constant temperature water bath shaker, and fermented continuously for 60 hours at 140rpm and 27°C;

[0037] (3) Centrifuge ...

Embodiment 2

[0044] A preparation method of a petroleum degrading bacterial agent, comprising the following steps:

[0045] (1) The strains of Caulobacter ineruis, Candida parapsilosis, Brevibacterium phenol-resistant, Arthrobacter globosa, and Septoria salinii were expanded to a cell concentration of 10 9 ~10 10 cfu / g, mix Caulus ineruis, Candida parapsilosis, Brevibacterium phenol-resistant, Arthrobacter globosa and Septoria salinii according to the mass ratio of 3:2:2:1:1 to obtain the mixed bacteria kind;

[0046] (2) Autoclaving the liquid fermentation medium for 15-30min, in the aseptic operating table, inoculate the mixed strains obtained in step (1) into the sterilized liquid fermentation medium, the mixed strains and the liquid fermentation medium The weight ratio of the mixture is 1:10, and the liquid fermentation medium inoculated with the mixed strains is placed in a constant temperature water bath shaker, and fermented continuously for 55 hours at 140rpm and 28°C;

[0047] ...

Embodiment 3

[0054] A preparation method of a petroleum degrading bacterial agent, comprising the following steps:

[0055] (1) The strains of Caulobacter ineruis, Candida parapsilosis, Brevibacterium phenol-resistant, Arthrobacter globosa, and Septoria salinii were expanded to a cell concentration of 10 9 ~10 10 cfu / g, mix Caulus ineruis, Candida parapsilosis, Brevibacterium phenol-resistant, Arthrobacter globosa and Septoria salinii according to the mass ratio of 3:2:2:1:1 to obtain the mixed bacteria kind;

[0056] (2) Autoclaving the liquid fermentation medium for 15-30min, in the aseptic operating table, inoculate the mixed strains obtained in step (1) into the sterilized liquid fermentation medium, the mixed strains and the liquid fermentation medium The weight ratio is 1:15, and the liquid fermentation medium inoculated with the mixed strains is placed in a constant temperature water bath shaker, and fermented continuously for 48 hours at 140rpm and 30°C;

[0057] (3) Centrifuge ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com