A method and device for manufacturing artificial bone based on ultrasonic processing

A technology of ultrasonic processing and manufacturing method, which is applied in the direction of manufacturing tools, metal processing equipment, bone implants, etc., which can solve the problems of limited product size, low porosity of porous titanium, and long processing time, so as to reduce the preparation of masks link, favorable for regrowth, and less material restriction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

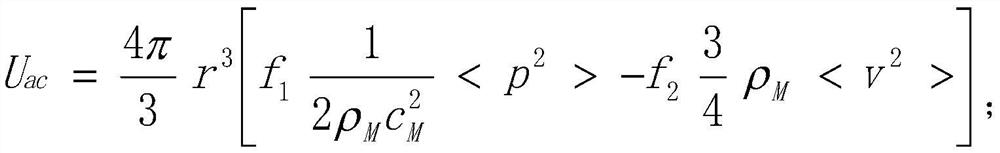

Method used

Image

Examples

Embodiment 1

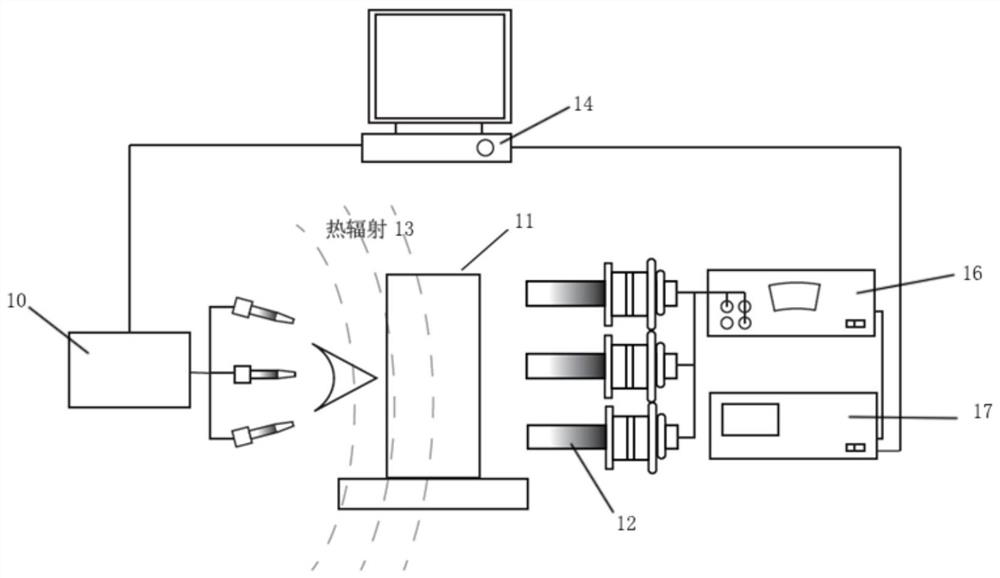

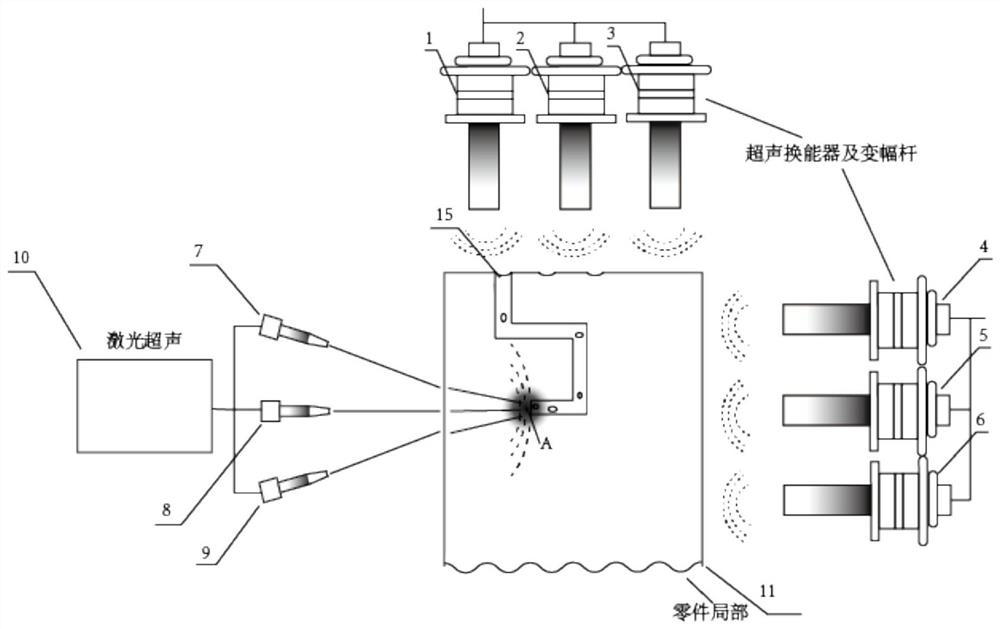

[0046] Embodiment one, adopt alloy Zr 0.75 Nb 0.25 As a bone substitute material, the alloy has good corrosion resistance, excellent strength and toughness, and its Young's modulus is about 29GPa, which is very similar to the Young's modulus of human bones (about 30GPa). Biocompatibility facilitates tissue growth in the bone void. Such as figure 2 Shown, is the processing material Zr 0.75 Nb 0.25 Alloy 11, labels 1 to 6 are horns whose frequency and power are controlled by a computer 14 . The laser ultrasonic device 10 receives the control signal from the computer 14 and converts it into an electrical signal and transmits it to the laser emitting probe 7 , the laser emitting probe 8 , and the laser emitting probe 9 .

[0047] In the early stage of processing, the computer 14 performs temperature control operation on the metal material through infrared thermal radiation or electromagnetic induction, and raises the material to the specified processing temperature C, which ...

Embodiment 2

[0051] Embodiment 2: Ti alloy with the same good performance is used, processed in the manner in Example 1, and the material-removed manufacturing of artificial bone is realized.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com