Process for recovering aluminium, iron and scandium from Bayer-process red mud powder

A Bayer red mud and aluminum recycling technology, applied in the direction of improving process efficiency, can solve the problems of polluting soil, air and groundwater, seriously endangering the natural environment, and affecting people's health, so as to achieve recycling, less wastewater discharge, and solution Handle simple effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

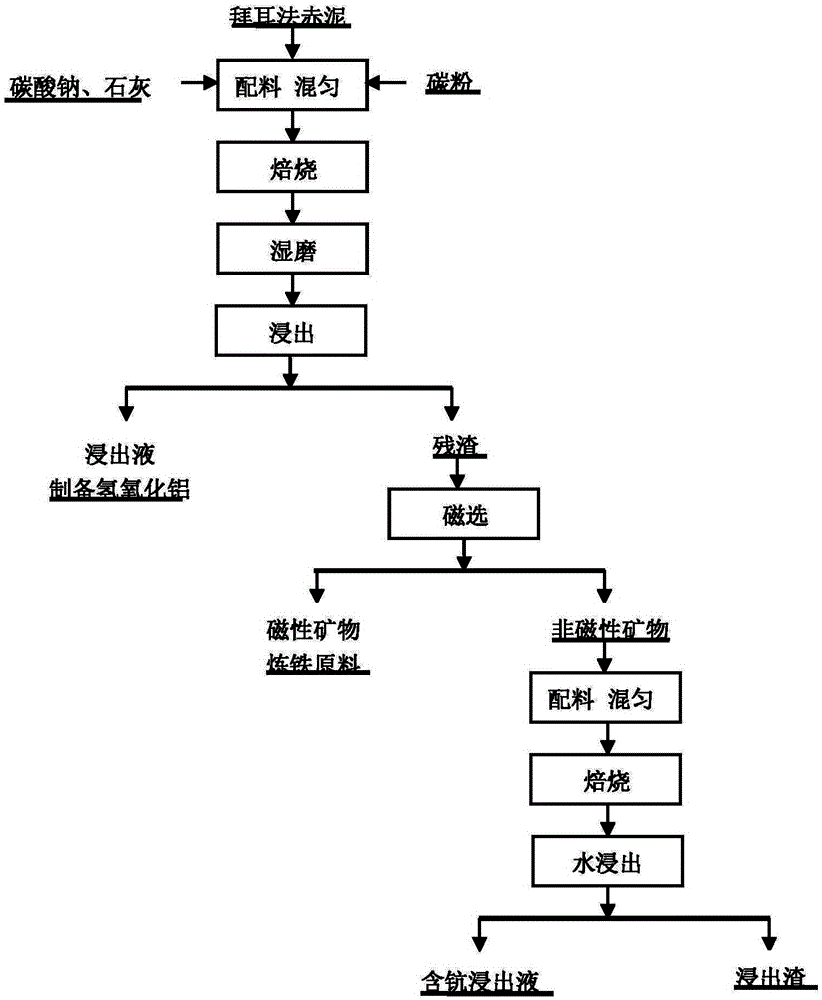

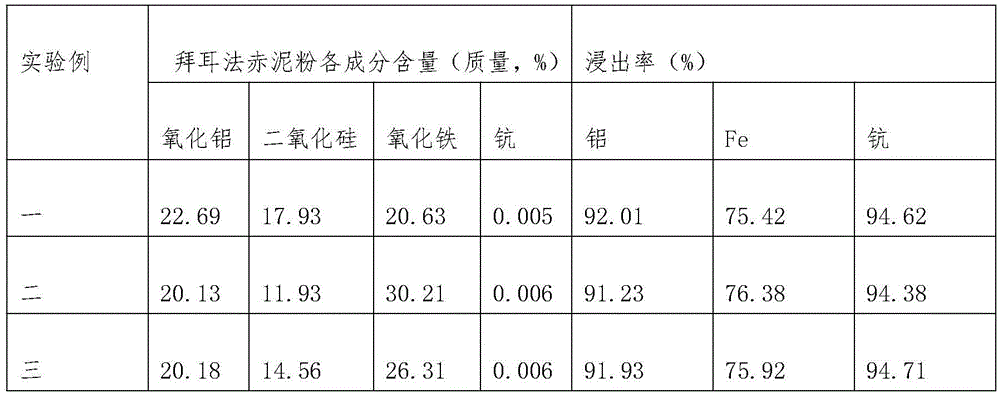

[0028] This embodiment provides a process for recovering aluminum, iron and scandium from red mud powder by Bayer method, such as figure 1 As shown, the specific steps are:

[0029] 1) Analyze the composition of the Bayer process red mud powder, and measure the content of Al2O3, iron oxide and silicon dioxide in the Bayer process red mud powder;

[0030] 2) Mix the Bayer process red mud powder with sodium carbonate, lime and carbon powder, place the mixed material in a ceramic crucible, and cover with a layer of 3-5mm thick reduced carbon powder (the main function is to isolate and prevent the reactant It will be oxidized again in contact with air), cover the lid and seal it tightly, and the mixing ratio of red mud powder, sodium carbonate, lime and reducing carbon powder should meet: the amount of sodium carbonate added (molar ratio) [Na 2 CO 3 ] / [Al 2 o 3 ]=1~1.1, the amount of lime added (molar ratio) [CaO] / [SiO 2 ] = 1.8 ~ 2, the amount of carbon powder added (mass ra...

Embodiment 2

[0043] This embodiment provides a process for recovering aluminum, iron and scandium from red mud powder by Bayer method, such as figure 1 As shown, the specific steps are:

[0044] 1) Analyze the composition of the Bayer process red mud powder, and measure the content of Al2O3, iron oxide and silicon dioxide in the Bayer process red mud powder;

[0045] 2) Mix the Bayer process red mud powder with sodium carbonate, lime and carbon powder, place the mixed material in a ceramic crucible, and cover with a layer of 3-5mm thick reduced carbon powder (the main function is to isolate and prevent the reactant It will be oxidized again in contact with air), cover the lid and seal it tightly, and the mixing ratio of red mud powder, sodium carbonate, lime and reducing carbon powder should meet: the amount of sodium carbonate added (molar ratio) [Na 2 CO 3 ] / [Al 2 o 3 ]=1~1.1, the amount of lime added (molar ratio) [CaO] / [SiO 2 ] = 1.8 ~ 2, the amount of carbon powder added (mass rati...

Embodiment 3

[0051] This embodiment provides a process for recovering aluminum, iron and scandium from red mud powder by Bayer method, such as figure 1 As shown, the specific steps are:

[0052] 1) Analyze the composition of the Bayer process red mud powder, and measure the content of Al2O3, iron oxide and silicon dioxide in the Bayer process red mud powder;

[0053] 2) Mix the Bayer process red mud powder with sodium carbonate, lime and carbon powder, place the mixed material in a ceramic crucible, and cover with a layer of 3-5mm thick reduced carbon powder (the main function is to isolate and prevent the reactant It will be oxidized again in contact with air), cover the lid and seal it tightly, and the mixing ratio of red mud powder, sodium carbonate, lime and reducing carbon powder should meet: the amount of sodium carbonate added (molar ratio) [Na 2 CO 3 ] / [Al 2 o 3 ]=1~1.1, the amount of lime added (molar ratio) [CaO] / [SiO 2 ] = 1.8 ~ 2, the amount of carbon powder added (mass ra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com