Waste-heat utilization method and device for indirect heating type sintering system

A heating and indirect technology, applied in the field of alumina production, can solve the problems of increasing energy consumption and production cost of the production system, difficulty in meeting emission standards, and low heat exchange efficiency, so as to facilitate dust collection and emission treatment, and reduce equipment investment , Reduce the effect of heating temperature difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

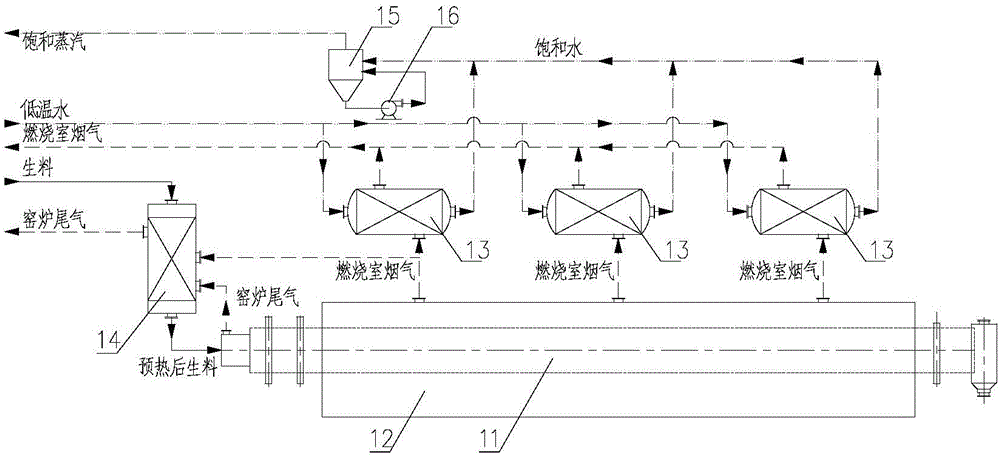

[0045] Such as figure 1 As shown, the waste heat utilization device of the indirect heating sintering system in this embodiment mainly includes: kiln 11, combustion chamber 12, air-water heat exchanger 13, raw meal preheater 14, flash evaporator 15, saturated water circulation pump 16, etc. The specific structure is as follows:

[0046] The combustion chamber 12 is located on the outside of the kiln 11, and indirectly heats the materials in the kiln (rotary kiln or vertical furnace), and the outlet of the combustion flue gas is connected to the air-water heat exchanger 13 through a pipeline; the air-water heat exchanger 13 is set There are low-temperature water inlet and saturated water outlet, and the saturated water outlet is connected to the flash evaporator 15 through pipelines, and the saturated steam generated then goes to other processes through the saturated steam outlet of the flash evaporator 15 through pipelines; the inlet port of the saturated water circulation pum...

Embodiment 2

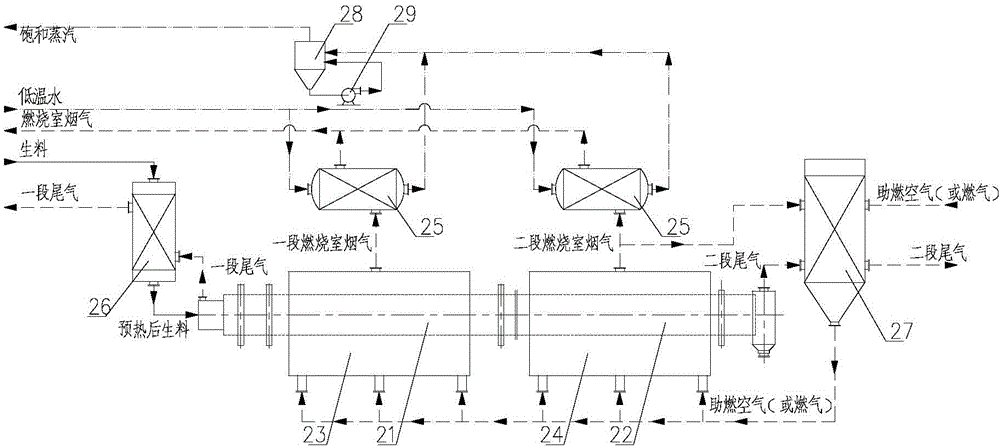

[0050] Such as figure 2 As shown, the waste heat utilization device of the indirect heating sintering system in this embodiment mainly includes a first-stage kiln 21, a second-stage kiln 22, a first-stage combustion chamber 23, a second-stage combustion chamber 24, an air-water heat exchanger 25, and raw meal preheating 26, gas heat exchanger 27 (air or gas), flash evaporator 28, saturated water circulation pump 29, etc., the specific structure is as follows:

[0051] The first-stage combustion chamber 23 and the second-stage combustion chamber 24 are respectively located outside the first-stage kiln 21 and the second-stage kiln 22, and indirectly heat the materials in the kiln (first-stage kiln 21, second-stage kiln 22), and the combustion flue gas (one-stage combustion chamber flue gas, second-stage combustion chamber flue gas) are respectively connected to the gas-water heat exchanger 25 through pipelines, and the gas-water heat exchanger 25 divides a branch pipeline and i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com