Chip frame with high bonding wire quality and manufacturing method thereof

A manufacturing method and framework technology, applied in semiconductor/solid-state device manufacturing, electrical components, electric solid-state devices, etc., can solve the problems of unfavorable chip lead pin welding, slow welding speed, poor welding quality, etc., and achieve improved welding performance and welding High quality, fast welding speed and high quality welding wire

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

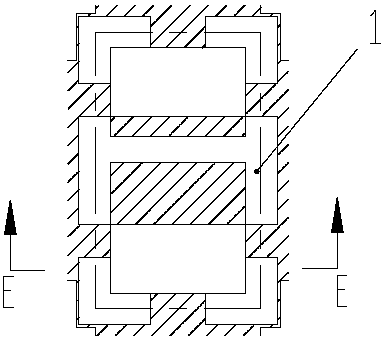

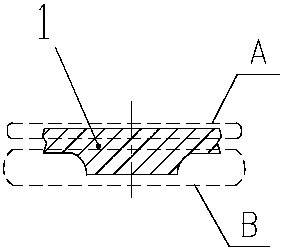

[0033] In this embodiment, the chip frame is used for the chip frame of the SOD882 type, such as Figure 1-Figure 4 As shown, the chip frame with high wire bonding quality in this embodiment includes a frame body 1, the frame body is divided into a frame front for packaging chips and a frame back corresponding to the frame front, and the frame front is coated with palladium A silver-gold-nickel protective layer 2, the back of the frame is coated with a nickel-palladium-gold protective layer 3.

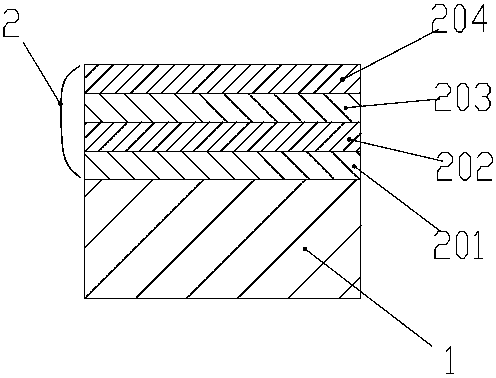

[0034] In this embodiment, the palladium-silver-gold-nickel protective layer 2 coated on the front side of the frame is a multilayer structure from the inside to the outside, and from the inside to the outside are the front Ni layer 201, the front Pd layer 202, and the front Ag layer 203. and the front Au layer 204, wherein Ni is nickel, Pd is palladium, Ag is silver, and Au is gold. A small amount of nickel can improve the thermal stability of the alloy in hydrogen, while palladium a...

Embodiment 2

[0050] In this embodiment, the chip frame is used for the chip frame of DFN3030 type, such as Figure 1-Figure 4 As shown, the chip frame with high wire bonding quality in this embodiment includes a frame body 1, the frame body is divided into a frame front for packaging chips and a frame back corresponding to the frame front, and the frame front is coated with palladium A silver-gold-nickel protective layer 2, the back of the frame is coated with a nickel-palladium-gold protective layer 3.

[0051] In this embodiment, the palladium-silver-gold-nickel protective layer 2 coated on the front side of the frame is a multilayer structure from the inside to the outside, and from the inside to the outside are the front Ni layer 201, the front Pd layer 202, and the front Ag layer 203. and the front Au layer 204, wherein Ni is nickel, Pd is palladium, Ag is silver, and Au is gold. A small amount of nickel can improve the thermal stability of the alloy in hydrogen, while palladium and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com