A kind of flower-shaped manganese cobaltate and preparation method thereof

A manganese cobaltate and flower-like technology, which is applied in the field of inorganic transition metal composite oxide material synthesis, can solve the problems of complicated and complicated preparation methods of flower-like manganese cobaltate, achieve easy implementation of control conditions and means, and improve electrochemical energy storage. The effect of performance, process method short answer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

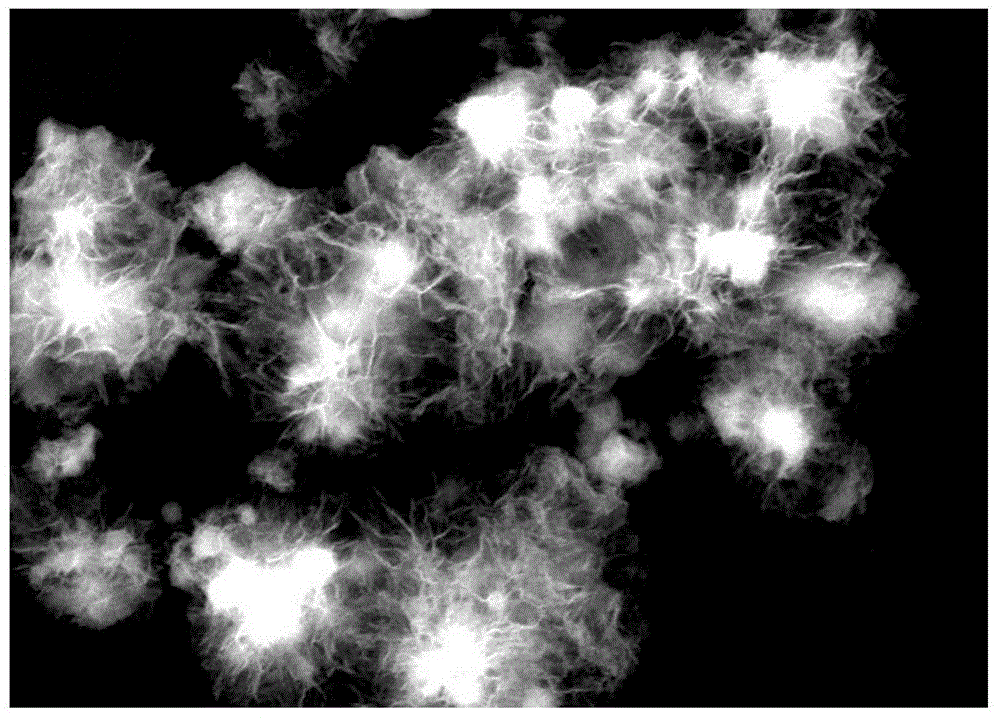

[0029] The flower-like structure of the flower-like manganese cobaltate provided in the examples is formed by assembling nanosheets and solid cores. The nanosheets are arranged on the surface of the solid core and intertwined with each other. The average thickness of the nanosheets in this embodiment is 5nm to 60nm. For example, the average thickness of the nanosheets is 5nm, 10nm, 15nm, 30nm, 60nm, etc. The specific thickness can be prepared according to specific needs; the solid core in this embodiment The average size of the solid core is 0.1 μm to 1.0 μm, and the specific average size of the solid core body can be 0.1 μm, 0.3 μm, 0.5 μm, 0.7 μm, 1.0 μm and so on.

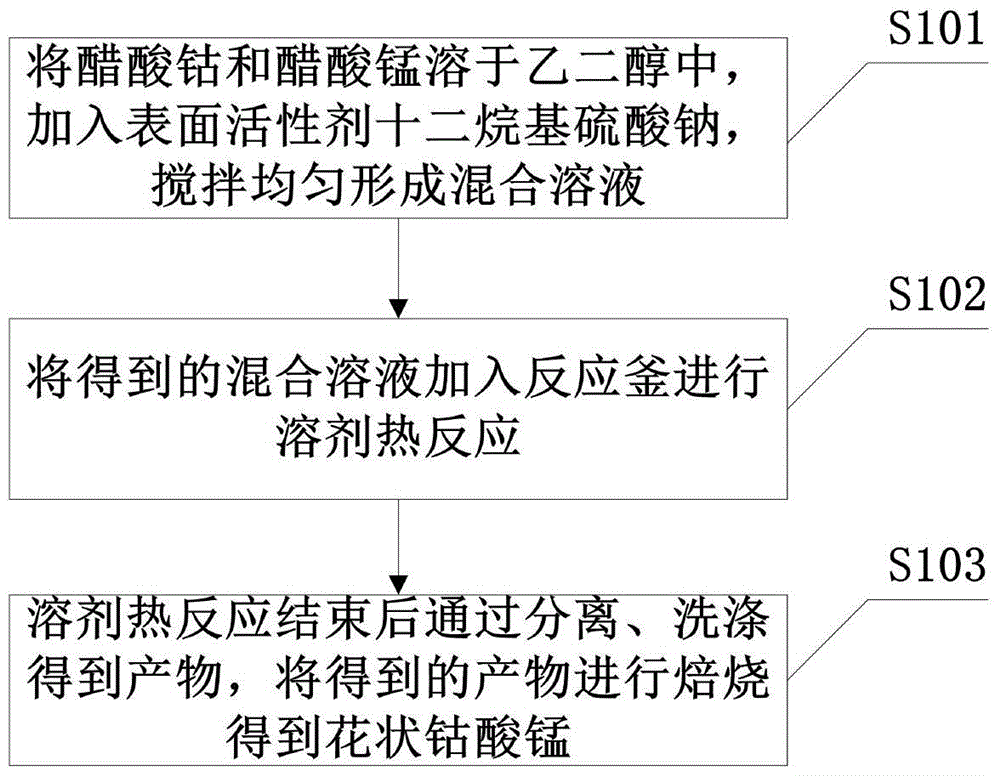

[0030] This embodiment also provides a method for preparing the flower-shaped manganese cobaltate as described above, please refer to figure 1 shown, including:

[0031] Step 101: dissolving cobalt acetate and manganese acetate in ethylene glycol, adding surfactant sodium lauryl sulfate, stirring evenly to for...

Embodiment 2

[0040] In order to better understand the present invention, the present invention will be further described below in conjunction with a specific preparation example.

[0041] Weigh 0.37g cobalt acetate (Co(Ac) 2 4H 2 O) and 0.18g manganese acetate (Mn(Ac) 2 4H 2 O) dissolved in 30ml ethylene glycol (Co 2+Concentration is 50mmol / l), then add 0.29g sodium dodecyl sulfate (SDS, Co 2+ : and SDS molar ratio is 1.5), after stirring evenly, the solution is transferred to a 50ml stainless steel hydrothermal kettle, heated to 160°C and kept for 15h, after the reaction, the product is separated, washed, dried, and then roasted at 350°C for 2h to obtain a black powder product .

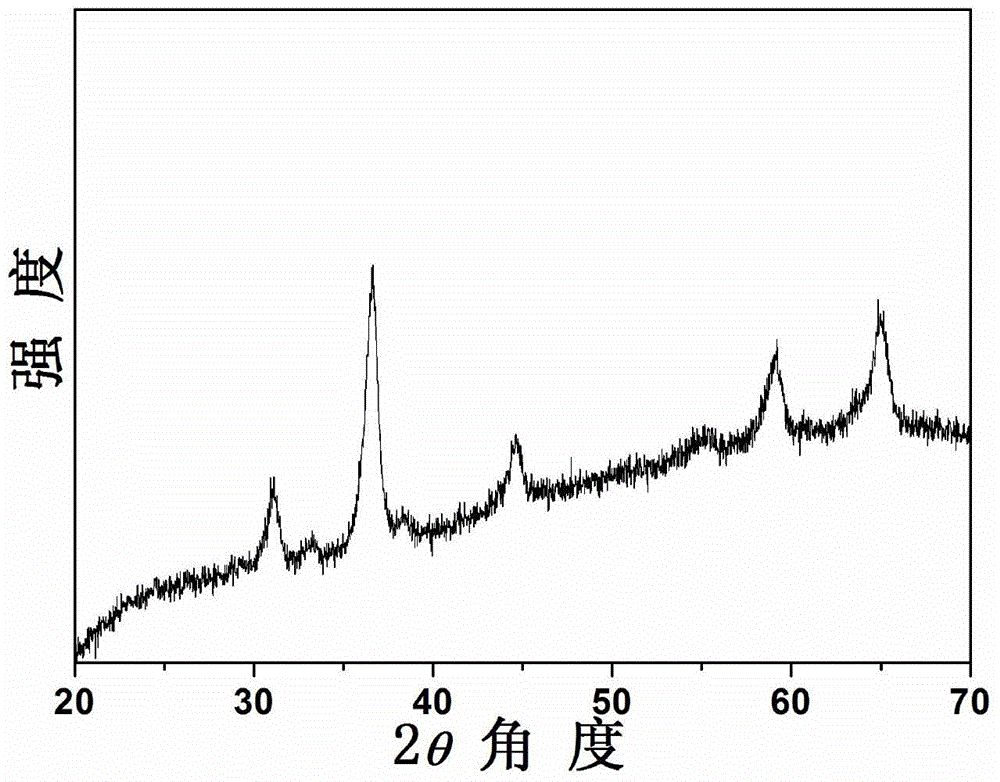

[0042] The black powder product prepared above was subjected to an XRD test on an X'Pert PROMPD multifunctional X-ray diffractometer produced by Panalytical Company of the Netherlands (Panalytical). figure 2 It is the XRD spectrum of the black powder product obtained in this example, and the diffraction p...

Embodiment 3

[0050] In order to better understand the present invention, the present invention will be further described below in conjunction with a specific preparation example.

[0051] Weigh 0.67g cobalt acetate (Co(Ac) 2 4H 2 O) and 0.33g manganese acetate (Mn(Ac) 2 4H 2 O) dissolved in 30ml ethylene glycol (Co 2+ Concentration is 90mmol / l), then add 0.78g sodium dodecyl sulfate (SDS, Co 2+ : and SDS molar ratio is 1.0), after stirring evenly, the solution is transferred to a 50ml stainless steel hydrothermal kettle, heated to 190°C and kept for 6h, after the reaction, the product is separated, washed, dried, and then roasted at 350°C for 2h to obtain a black powder product . XRD spectrum analysis product is manganese cobaltate with spinel structure. SEM photos show that the product is a flower-like structure, which is formed by the assembly of solid core and outer flexible nanosheets, and its size is 2 μm to 3 μm. The molar ratio of cobalt and manganese elements measured by EDS...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com