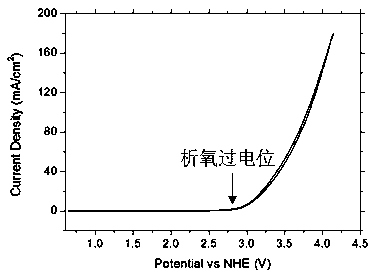

Titanium-based positive electrode with high oxygen evolution overpotential and preparing method thereof

An oxygen evolution overpotential and electrode technology, which is applied in the field of anode electrodes, can solve the problems of low oxygen evolution overpotential, etc., and achieve the effects of improving oxygen evolution overpotential and improving physical and chemical properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] This embodiment includes the following steps:

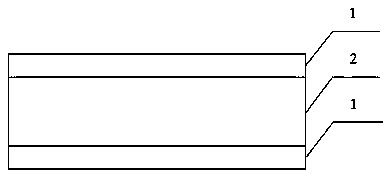

[0025] Step (1), as attached figure 1 As shown, choose a thickness of 0.5mm and an area of 9cm 2 The titanium plate is used as the titanium substrate, and the surface of the titanium plate is processed by sandblasting process, and the size of the sand grains is 300 mesh. Put the sandblasted titanium plate into the alcohol solution for ultrasonic cleaning for 10 minutes, then corrode the cleaned titanium plate with 10% oxalic acid for 30 minutes, then rinse the corroded titanium plate with deionized water, and finally The titanium plate was blown dry with nitrogen gas.

[0026] Step (2), weigh the SnCl of 8.0g 4 ·5H 2 O and put it into 50mL of alcohol, and use a magnetic stirrer to fully stir to obtain a clear and uniform solution.

[0027] Step (3), weigh 0.20g of CuNO 3 And put it into the solution obtained in step 2, and use a magnetic stirrer to fully stir to obtain a clear and uniform solution.

[0028] Step (...

Embodiment 2

[0032] This embodiment includes the following steps:

[0033] Step (1), as attached figure 1 As shown, choose a thickness of 0.5mm and an area of 9cm 2 The titanium mesh is used as the titanium substrate, and the surface of the titanium plate is processed by sandblasting, and the size of the sand particles is 300 mesh. Put the sandblasted titanium plate into the alcohol solution for ultrasonic cleaning for 10 minutes, then corrode the cleaned titanium mesh with 18% hydrochloric acid for 30 minutes, then rinse the corroded titanium mesh with deionized water, and finally use The titanium plate was blown dry with nitrogen gas.

[0034] Step (2), weigh the SnCl of 8.0g 4 ·5H 2 O, and put it into the ethanol of 50mL, utilize magnetic stirrer to carry out thorough stirring to obtain clear and homogeneous solution.

[0035] Step (3), weigh 0.1g of CuNO 3 And put it into the solution obtained in step 2, and use a magnetic stirrer to fully stir to obtain a clear and uniform sol...

Embodiment 3

[0040] This embodiment includes the following steps:

[0041] Step (1), as attached figure 1 As shown, a titanium plate with a thickness of 1 mm and an area of 9 cm2 is selected as the titanium substrate, and the surface of the titanium plate is processed by sandblasting, and the size of the sand grains is 300 mesh. Put the sandblasted titanium plate into the alcohol solution for ultrasonic cleaning for 10 minutes, then corrode the cleaned titanium plate with 10% oxalic acid for 30 minutes, then rinse the corroded titanium plate with deionized water, and finally The titanium plate was blown dry with nitrogen gas.

[0042] Step (2), weigh the SnCl of 7.0g 2 2H 2 O and put it into 50mL of alcohol, and use a magnetic stirrer to fully stir to obtain a clear and uniform solution.

[0043] Step (3), weigh the CuNO of 0.08g 3And put it into the solution obtained in step 2, and use a magnetic stirrer to fully stir to obtain a clear and uniform solution.

[0044] Step (4), pick...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com