A method for reclaiming phosphoric acid from an electrolytic mixed acid solution

A technology of mixing acid solution and phosphoric acid, which is applied in the direction of electrolysis components, electrolysis process, chemical instruments and methods, etc., can solve the problems of high energy consumption and difficult control of the process, and achieve simple process flow, simple steps and low energy consumption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

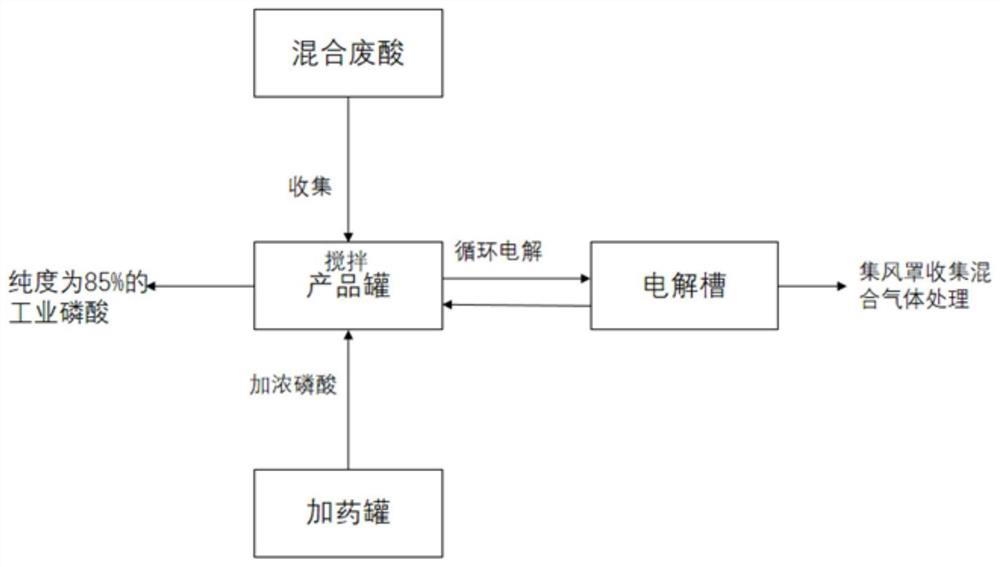

[0029] A method for reclaiming phosphoric acid from an electrolytic mixed acid solution, characterized in that it comprises the following steps:

[0030] Step A: collecting mixed waste acid, which contains phosphoric acid, nitric acid and acetic acid, the mass concentration of phosphoric acid is 40%, the mass concentration of acetic acid is 15%, and the mass concentration of nitric acid is 2%. Stored in product tanks, agitated;

[0031] Step B: The mixed acid stored in the product tank in step A enters the electrolytic tank for circulating electrolysis, and the waste liquid is circulated between the electrolytic tank and the product tank at a speed of 130L / h, and the impurities per ton of water are electrolyzed The time is 24 hours; nitric acid is reduced at the cathode of the electrolytic cell, acetic acid is oxidized at the anode of the electrolytic cell, and different electrolytic reactions occur on the surface of the cathode and anode respectively. Mainly carry out the ox...

Embodiment 2

[0037] A method for reclaiming phosphoric acid from an electrolytic mixed acid solution, characterized in that it comprises the following steps:

[0038]Step A: collecting mixed waste acid, which contains phosphoric acid, nitric acid and acetic acid, the mass concentration of phosphoric acid is 60%, the mass concentration of acetic acid is 25%, and the mass concentration of nitric acid is 1%. Stored in product tanks, agitated;

[0039] Step B: The mixed acid stored in the product tank in step A enters the electrolytic tank for circulating electrolysis, and the waste liquid is circulated between the electrolytic tank and the product tank at a speed of 120L / h, and the impurities are removed by electrolysis per ton of water. The time is 24 hours; nitric acid is reduced at the cathode of the electrolytic cell, acetic acid is oxidized at the anode of the electrolytic cell, and different electrolytic reactions occur on the surface of the cathode and anode respectively. Mainly carry...

Embodiment 3

[0046] A method for reclaiming phosphoric acid from an electrolytic mixed acid solution, characterized in that it comprises the following steps:

[0047] Step A: collecting mixed waste acid, which contains phosphoric acid, nitric acid and acetic acid, the mass concentration of phosphoric acid is 70%, the mass concentration of acetic acid is 35%, and the mass concentration of nitric acid is 2%. Stored in product tanks, agitated;

[0048] Step B: The mixed acid stored in the product tank in step A enters the electrolytic tank for circulating electrolysis, and the waste liquid is circulated between the electrolytic tank and the product tank at a speed of 110L / h, and the impurities per ton of water are electrolyzed The time is 24 hours; nitric acid is reduced at the cathode of the electrolytic cell, acetic acid is oxidized at the anode of the electrolytic cell, and different electrolytic reactions occur on the surface of the cathode and anode respectively. Mainly carry out the ox...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com