Waste-residue and magnesium-phosphate cement self-leveling mortar

A technology of magnesium phosphate cement and self-leveling mortar, applied in the field of construction, can solve the problems of loss of fluidity, high price, fast hydration and coagulation, etc., to achieve good wear resistance and acid and alkali corrosion resistance, increase the cost of use, production Processing simple effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

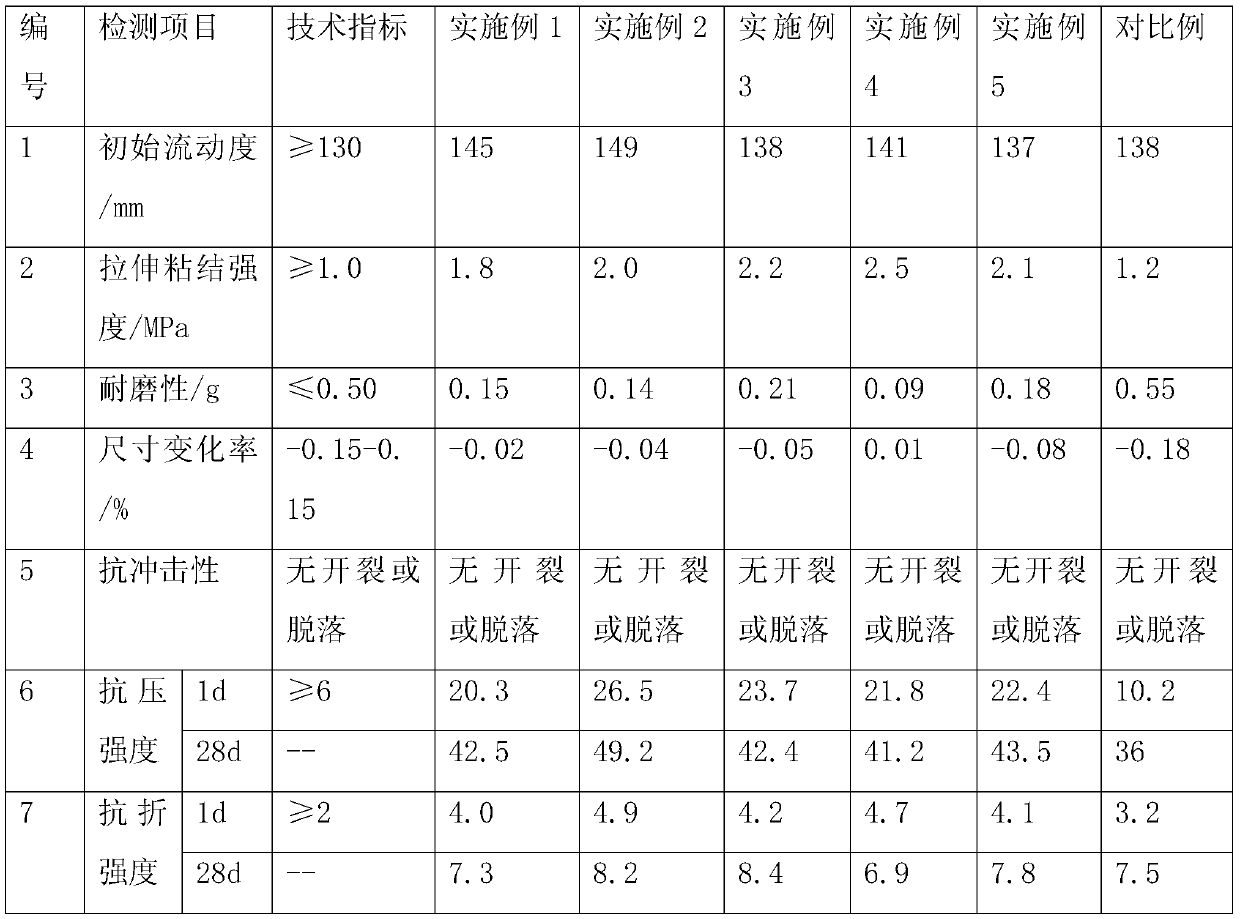

Examples

Embodiment 1

[0029] Example 1: Preparation of waste residue magnesium phosphate cement self-leveling mortar

[0030] Unit: parts by mass.

[0031] (1) Magnesium phosphate cement 33, including magnesium oxide 18.7, potassium dihydrogen phosphate 14.3;

[0032] (2) ceramic waste slag 30;

[0033] (3) fine aggregate 34;

[0034] (4) Boric acid retarder 0.7, special retarder water reducer 2.3;

[0035] Preparation method and preparation before use:

[0036] First mix the above (1)-(3) with boric acid retarder evenly, and then add special retarder water reducer before use.

[0037] Specifically, pour water into the mixing tank, then add the special retarding water reducer (liquid) into the water, then pour the mixture of the above (1)-(3) and boric acid retarder into the bucket, and use planetary The mortar mixer can be stirred for 1.5-2 minutes, and the water consumption is 0.18-0.20:1 of the weight of waste residue magnesium phosphate cement self-leveling mortar.

Embodiment 2

[0038] Example 2: Preparation of waste residue magnesium phosphate cement self-leveling mortar

[0039] Unit: parts by mass.

[0040] (1) Magnesium phosphate cement 38, including magnesium oxide 21.8, potassium dihydrogen phosphate 16.2

[0041] (2) Ceramic waste 27

[0042] (3) Fine aggregate 31

[0043] (4) Boric acid retarder 0.8, special retarder water reducer 3.2

[0044] The preparation method and the preparation before use are the same as in Example 1.

Embodiment 3

[0045] Example 3: Preparation of waste residue magnesium phosphate cement self-leveling mortar

[0046] Unit: parts by mass.

[0047] (1) Magnesium phosphate cement 35, of which magnesium oxide 17.6, potassium dihydrogen phosphate 13.4

[0048] (2) Ceramic waste 28

[0049] (3) Fine aggregate 33.4

[0050] (4) Boric acid retarder 0.5, special retarder water reducer 3.1

[0051] The preparation method and the preparation before use are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com