A method for recovering and utilizing exhaust tail gas synthesized from organosilicon crude monomer

A technology of organosilicon and tail gas, which is applied in the direction of organic chemistry, chemical instruments and methods, and compounds of group 4/14 elements of the periodic table, can solve the problems of increased cooling and recovery of methyl chloride towers, environmental pollution, etc., to reduce consumption, The effect of reducing environmental pollution and saving production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

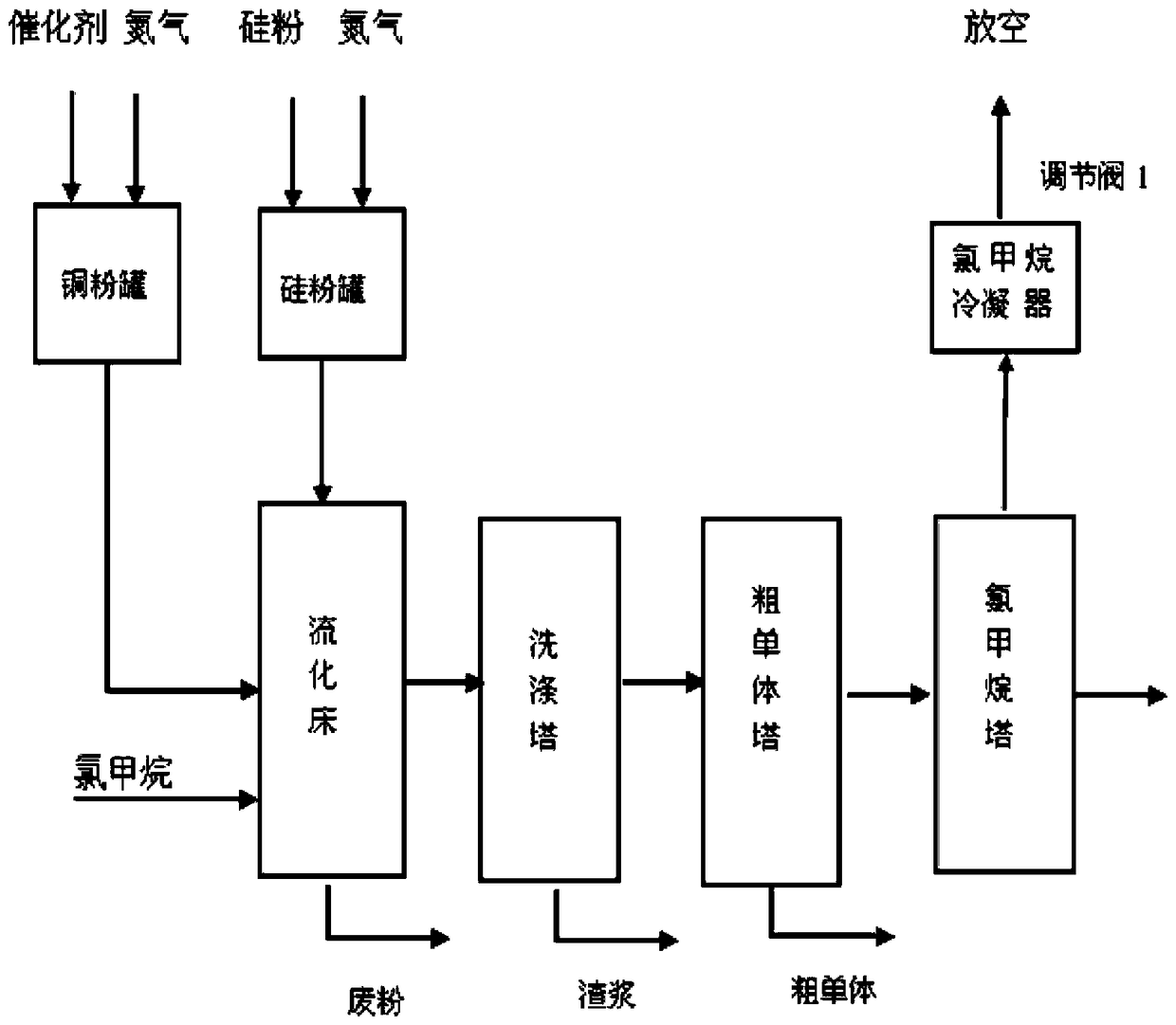

Problems solved by technology

Method used

Image

Examples

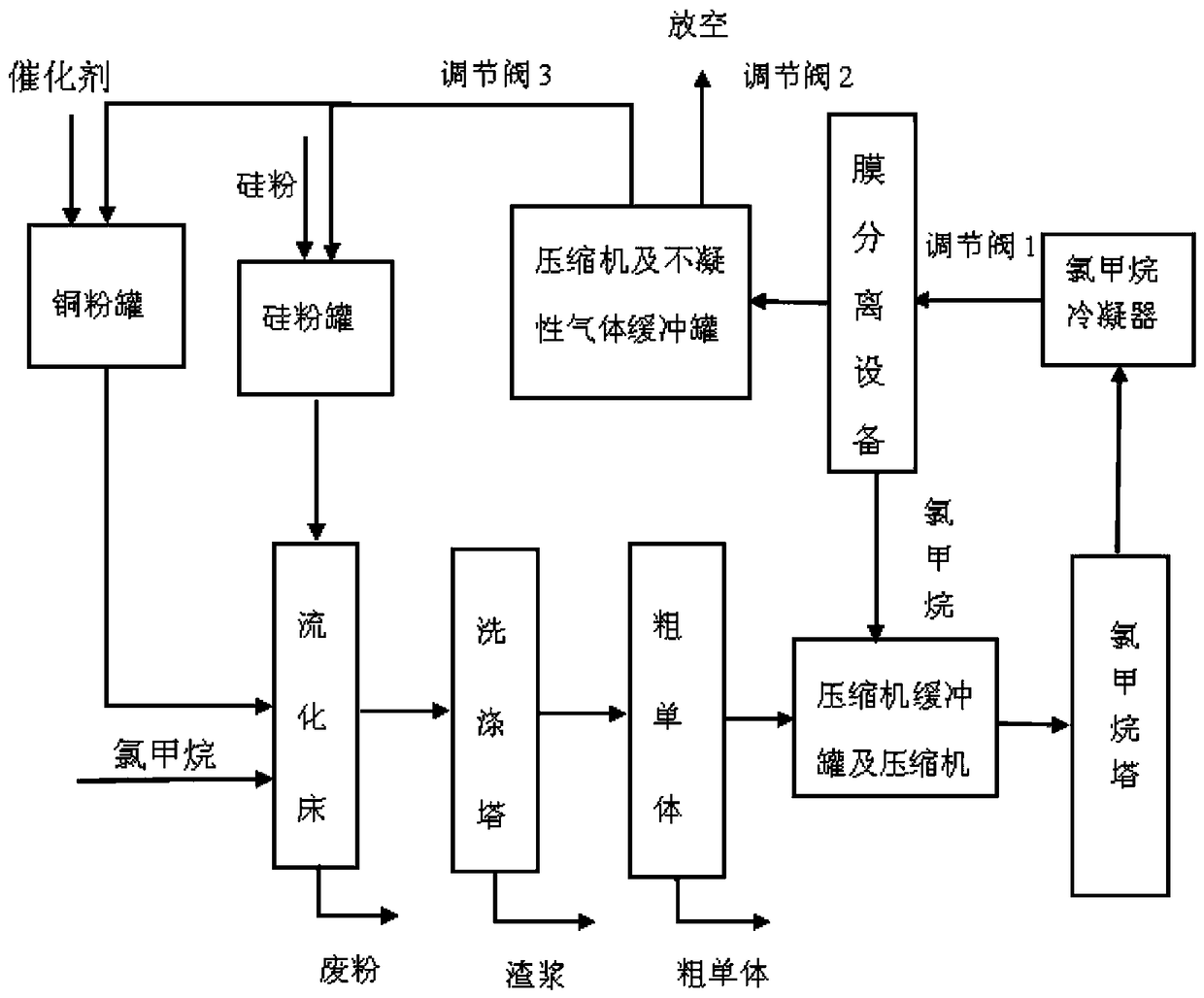

Embodiment 1

[0014] Embodiment 1: The first automatic regulating valve of the methyl chloride condenser is set to automatically regulate the pressure to be 0.9Mpa. If it is higher than this value, the regulating valve is opened, and the exhaust tail gas is discharged to the membrane separation equipment; the noncondensable gas buffer tank is vented to the second automatic regulation The valve is set to automatically adjust the pressure to 0.9Mpa. If it is higher than this value, the regulating valve will be opened to open the air; the third automatic regulating valve will be controlled on and off according to whether the material is pressed or not; the compressor will continue to work for the recovery of methyl chloride. When boosting is not performed, the pressure of the methyl chloride condenser is stable at about 0.9Mpa, the pressure of the tail gas buffer tank is stable at about 0.9Mpa, the non-condensable gas buffer tank is stably emptied, and the compressor continues to work normally t...

Embodiment 2

[0015] Embodiment 2: The first automatic regulating valve of the methyl chloride condenser is set to automatically adjust the pressure to be 0.95Mpa. If it is higher than the changed value, the regulating valve is opened, and the exhaust tail gas is discharged to the membrane separation equipment; the non-condensable gas buffer tank is vented to the second automatic regulation The valve is set to automatically adjust the pressure to 0.85Mpa. If it is higher than this value, the regulating valve will be opened to open the air; the third automatic regulating valve will be controlled on and off according to whether the material is pressed or not; the compressor will continue to work for the recovery of methyl chloride. When boosting is not performed, the pressure of the methyl chloride condenser is stable at about 0.95Mpa, the pressure of the tail gas buffer tank is stable at about 0.85Mpa, the tail gas buffer tank is stably emptied, and the compressor continues to work normally to...

Embodiment 3

[0016] Embodiment 3: the first automatic regulating valve of the methyl chloride condenser is set to automatically adjust the pressure to be 0.9Mpa, if it is higher than the changed value, the regulating valve is opened, and the vented tail gas is discharged to the membrane separation equipment; the non-condensable gas buffer tank is vented to the second automatic regulation The valve is set to automatically adjust the pressure to 0.8Mpa. If it is higher than this value, the regulating valve will be opened to open the air; the third automatic regulating valve will be controlled on and off according to whether the material is pressed or not; the compressor will continue to work for the recovery of methyl chloride. When boosting is not performed, the pressure of the methyl chloride condenser is stable at about 0.9Mpa, the pressure of the tail gas buffer tank is stable at about 0.8Mpa, the tail gas buffer tank is stably emptied, and the compressor continues to work normally to reco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com