A kind of water-based pressure-sensitive adhesive and preparation method thereof

A pressure-sensitive adhesive, water-based technology, applied in the direction of adhesive types, adhesive additives, non-polymer adhesive additives, etc. problem, to achieve the effect of increasing the cross-linking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

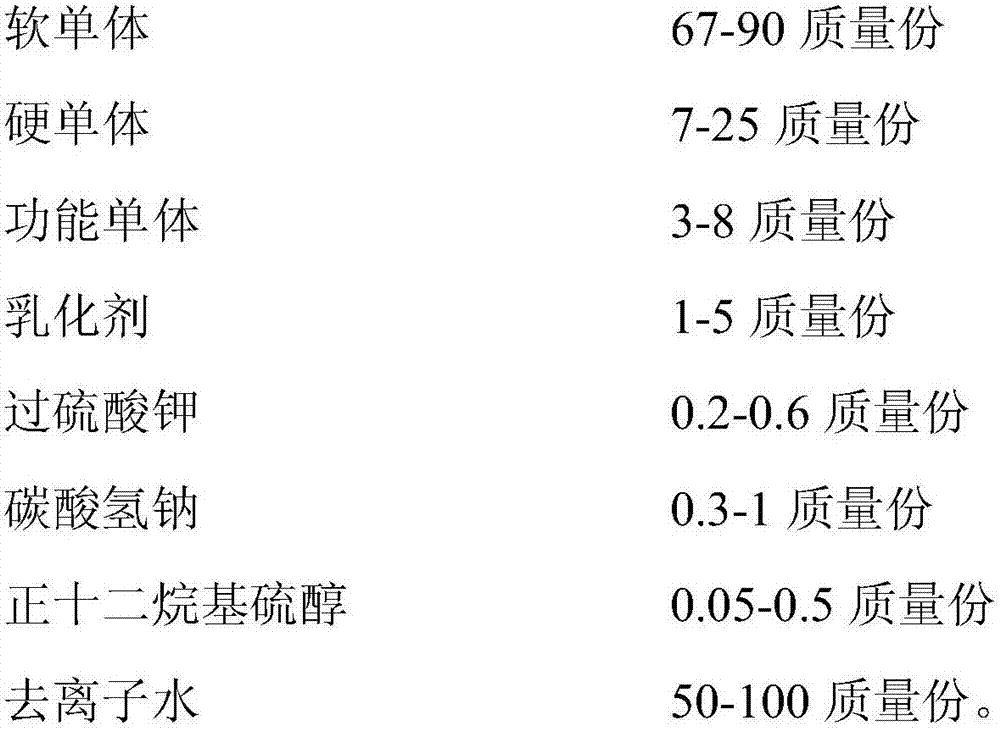

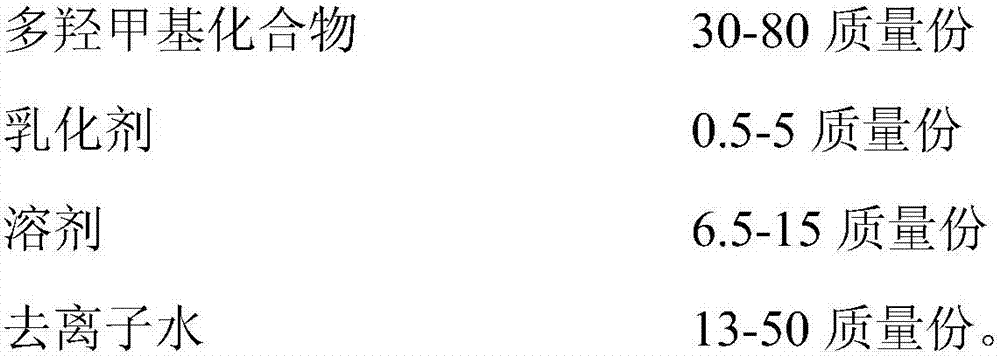

[0037] A water-based pressure-sensitive adhesive, which is composed of a polymer emulsion and a polymethylol compound emulsion, and the parts of each component are as follows:

[0038] 97 parts by mass of polymer emulsion

[0039] 3 parts by mass of polymethylol compound emulsion.

[0040] The preparation steps of the above-mentioned water-based pressure-sensitive adhesive are:

[0041] (1) In the first reactor, add 87 parts by mass of butyl acrylate, 8 parts by mass of methyl methacrylate, 2 parts by mass of acrylic acid, 2 parts by mass of methylol acrylamide, 1 part by mass of acrylamide, 2 parts by mass of Parts of octylphenol polyoxyethylene ether, 1 mass part of sodium lauryl sulfate, 0.4 mass part of potassium persulfate, 0.1 mass part of n-dodecyl mercaptan and 40 mass parts of deionized water, at room temperature, at 3000 rpm Stir 30min under the rotating speed of / minute, obtain pre-emulsion; Then pre-emulsion is divided into two parts, wherein, the first part of ...

Embodiment 2

[0046] A water-based pressure-sensitive adhesive, which is composed of a polymer emulsion and a polymethylol compound emulsion, and the parts of each component are as follows:

[0047] 99 parts by mass of polymer emulsion

[0048] 1 part by mass of polymethylol compound emulsion.

[0049] The preparation steps of the above-mentioned water-based pressure-sensitive adhesive are:

[0050] (1) In the first reactor, add 32 parts by mass of butyl acrylate, 35 parts by mass of isooctyl acrylate, 15 parts by mass of methyl methacrylate, 10 parts by mass of methyl acrylate, 2 parts by mass of acrylic acid, 5 parts by mass of Parts of methylol acrylamide, 1 part by mass of acrylamide, 1 part by mass of nonylphenol polyoxyethylene ether ammonium sulfate, 0.38 parts by mass of potassium persulfate, 0.5 parts by mass of n-dodecyl mercaptan and 25 parts by mass of deionized water , at room temperature, stirring at a speed of 1000 rpm for 30 minutes to obtain a pre-emulsion; then divide th...

Embodiment 3

[0055] A water-based pressure-sensitive adhesive, which is composed of a polymer emulsion and a polymethylol compound emulsion, and the parts of each component are as follows:

[0056] 80 parts by mass of polymer emulsion

[0057] 20 parts by mass of polymethylol compound emulsion.

[0058] The preparation steps of the above-mentioned water-based pressure-sensitive adhesive are:

[0059] (1) In the first reactor, add 30 parts by mass of butyl acrylate, 60 parts by mass of isooctyl acrylate, 7 parts by mass of methyl methacrylate, 2 parts by mass of acrylic acid, 1 part by mass of methylol acrylamide, 3 parts by mass of nonylphenol polyoxyethylene ether ammonium sulfate, 2 parts by mass of sodium lauryl sulfate, 0.1 parts by mass of potassium persulfate, 0.05 parts by mass of n-dodecyl mercaptan and 50 parts by mass of deionized water, at room temperature Stirring at 2500 rev / min for 30min to obtain a pre-emulsion; then divide the pre-emulsion into two parts, wherein the firs...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com