Epoxy-modified waterborne alkyd resin and preparation method thereof

A water-based alkyd resin and epoxy modification technology, which is applied in the chemical industry, can solve the problems of cumbersome process and complicated preparation method of water-based alkyd resin, and achieve the effects of simple synthesis process, shortened hard-drying time, and improved stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

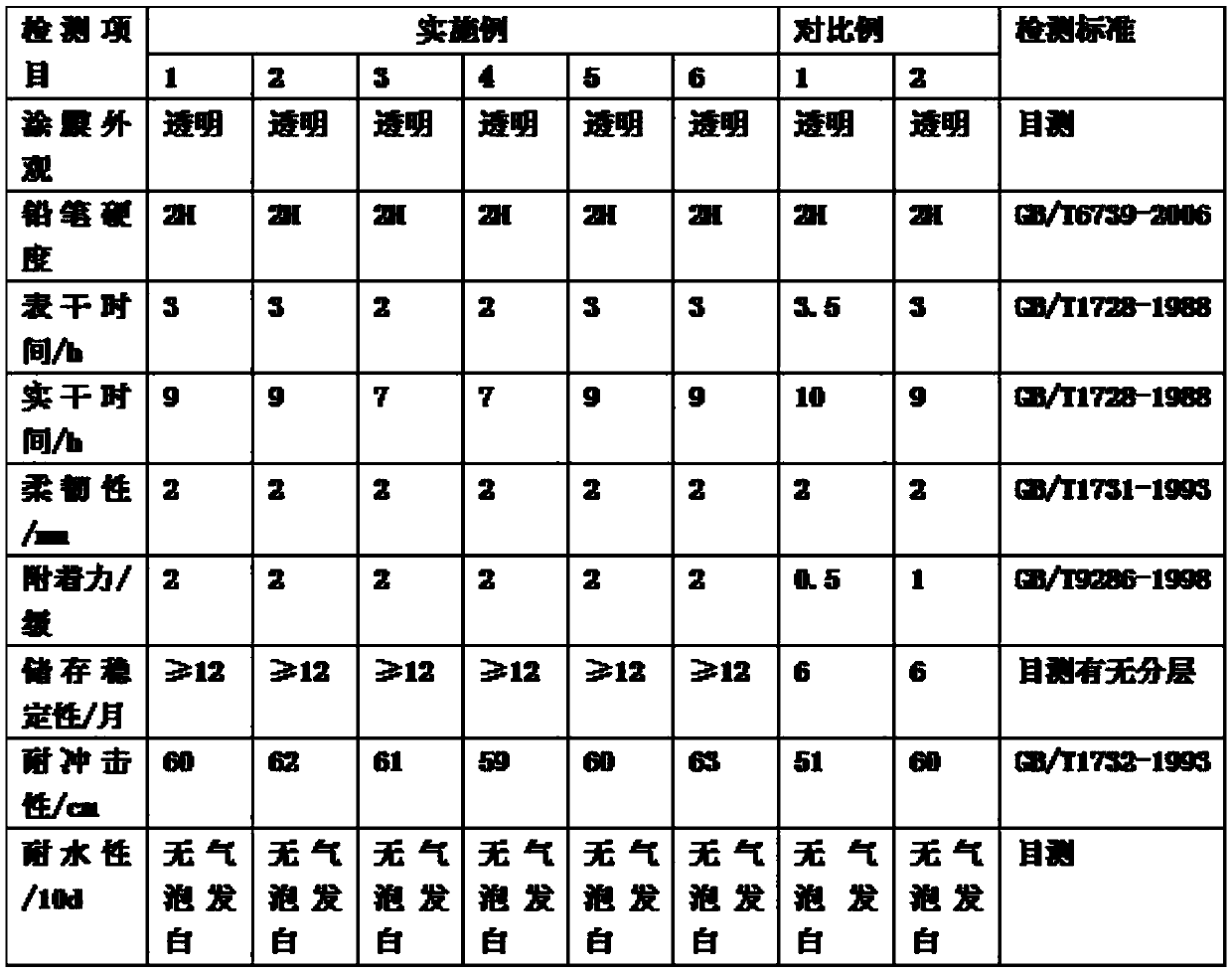

Examples

Embodiment 1

[0029] (1) Add tall oil acid 20g, abietic acid 4g, e20 epoxy resin 6g, neopentyl glycol 4g, trimethylolpropane 8g, pentaerythritol 5g, polyether N2102g, phthalic anhydride 10g in the reaction kettle , maleic anhydride 2g, xylene 5g, the temperature rises to 70-80°C and starts to stir. When the temperature rises to 140°C, slowly raise the temperature and keep rising 10°C per hour. When the temperature rises to 210°C, keep it warm for 2 hours. , start to measure the acid value of the reaction solution, take a sample every 1h to measure the acid value, when the acid value is below 13, take a sample every 0.5h to measure the acid value, and immediately cool down when the acid value is 10-11mgKOH / g;

[0030] (2) Cool down to 170-180°C, add 6g of trimellitic anhydride, pass in nitrogen, raise the temperature to 170±2°C, quickly cool down when the acid value reaches 43-48mgKOH / g, cool down to below 160°C, add ethylene glycol monobutyl ether 9g; below 120°C, add 9g of n-butanol; below...

Embodiment 2

[0032] (1) Add tall oil acid 22g, abietic acid 4g, e20 epoxy resin 6g, neopentyl glycol 4g, trimethylolpropane 8g, pentaerythritol 5g, polyether N2102g, phthalic anhydride 10g in the reaction kettle , maleic anhydride 2g, xylene 5g, the temperature rises to 70-80°C and starts to stir. When the temperature rises to 140°C, slowly raise the temperature and keep rising 10°C per hour. When the temperature rises to 210°C, keep it warm for 2 hours. , start to measure the acid value of the reaction solution, take a sample every 1h to measure the acid value, when the acid value is below 13, take a sample every 0.5h to measure the acid value, and immediately cool down when the acid value is 10-11mgKOH / g;

[0033] (2) Cool down to 170-180°C, add 6g of trimellitic anhydride, pass in nitrogen, raise the temperature to 170±2°C, quickly cool down when the acid value reaches 43-48mgKOH / g, cool down to below 160°C, add ethylene glycol monobutyl ether 9g; below 120°C, add 9g of n-butanol; below...

Embodiment 3

[0035] (1) Add tall oil acid 23g, abietic acid 4g, e20 epoxy resin 6g, neopentyl glycol 4g, trimethylolpropane 8g, pentaerythritol 5g, polyether N2102g, phthalic anhydride 10g in the reaction kettle , maleic anhydride 2g, xylene 5g, the temperature rises to 70-80°C and starts to stir. When the temperature rises to 140°C, slowly raise the temperature and keep rising 10°C per hour. When the temperature rises to 210°C, keep it warm for 2 hours. , start to measure the acid value of the reaction solution, take a sample every 1h to measure the acid value, when the acid value is below 13, take a sample every 0.5h to measure the acid value, and immediately cool down when the acid value is 10-11mgKOH / g;

[0036] (2) Cool down to 170-180°C, add 6g of trimellitic anhydride, pass in nitrogen, raise the temperature to 170±2°C, quickly cool down when the acid value reaches 43-48mgKOH / g, cool down to below 160°C, add ethylene glycol monobutyl ether 9g; below 120°C, add 9g of n-butanol; below...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com