Water-absorption desalination composite material for soil relic desalination, and applications thereof

A technology of composite materials and soil relics, applied in the field of water absorption and desalination composite materials, to achieve the effects of good desalination adaptability, convenient use, and improved desalination capacity and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

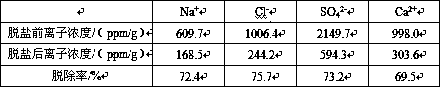

Embodiment 1

[0018] (1) Preparation of water-absorbing desalination materials

[0019] Soak 5.0g of starch in 25mL of deionized water and stir continuously for 30min to disperse the starch evenly in the solvent, heat to 80~85℃ for 50min under the protection of nitrogen, the system is in the form of translucent colloid, then cool down to 60℃, Add 25 mL of an aqueous solution of 0.36 g of potassium persulfate and 0.018 g of sodium sulfite, initiate the reaction at 60°C for 15 minutes, then add 200 mL of an aqueous solution of 20 g of acrylamide and 0.042 g of cross-linking agent N,N'-methylenebisacrylamide, and The graft polymerization reaction was carried out at 65° C. under protection, and the nitrogen flow was stopped after 2 hours of reaction. The obtained product is a gel-like polymer, which is taken out from the reactor after cooling, pulverized after being sufficiently dried, and passed through a 100-mesh sieve. Weigh 16.4595g of the above product, add 1.56g of kaolin, after uniform ...

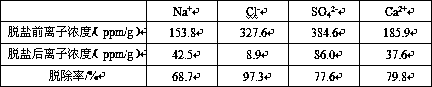

Embodiment 2

[0028] (1) Preparation of water-absorbing desalination materials

[0029] Soak 5.0g of starch in 25mL of deionized water and stir continuously for 30min to disperse the starch evenly in the solvent, heat it to 80~85℃ for 50min under the protection of nitrogen, the system is in the form of transparent colloid, then cool down to 60℃, add 25mL aqueous solution of 0.65g ammonium persulfate and 0.05g sodium sulfite was initiated at 65°C for 15min, then 200mL aqueous solution of 20g acrylamide and 0.042g cross-linking agent N,N'-methylenebisacrylamide was added, under nitrogen protection The graft polymerization reaction was carried out at 65°C, and the nitrogen flow was stopped after 2 hours of reaction. The obtained product is a gel-like polymer, which is taken out from the reactor after cooling, pulverized after being sufficiently dried, and passed through a 100-mesh sieve. Weigh 10.7254g of the above product, add 0.536g of silica gel, and after uniform dispersion, take 2g of th...

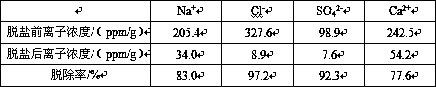

Embodiment 3

[0038] (1) Preparation of water-absorbing desalination materials

[0039] The preparation of the starch-acrylamide polymer is the same as above. After the preparation is completed, weigh 16.4595g of the product, add 2g of alumina, and after uniform dispersion, take 2g of the mixture and add 400ml of deionized water to form a uniformly dispersed viscous fluid. Apply it evenly on the carrier KC-X60 non-woven fabric, let it stand for 2 hours, dry it at 80°C for 6 hours, take it out, and cut it into a suitable shape for use after cooling.

[0040] (2) Desalination experiment

[0041] This experiment was carried out at room temperature, around 25 degrees Celsius.

[0042] Cut the sticking material into small pieces of 4*2cm for later use. Before the experiment, scrape an appropriate amount of salt content of 2%NaCl, 2%Na 2 SO 4 The surface soil of the test piece weighs about 100-200 mg, and is fixed in a 50ml solution. After the solution is dissolved and balanced, the supernata...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com