Algae and calcium containing inorganic ecological coating and preparation method thereof

An inorganic and ecological technology, applied in coatings and other directions, can solve problems such as VOC volatile pollution, and achieve the effect of increasing the gloss of the coating film, improving the rheological properties, and excellent water resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

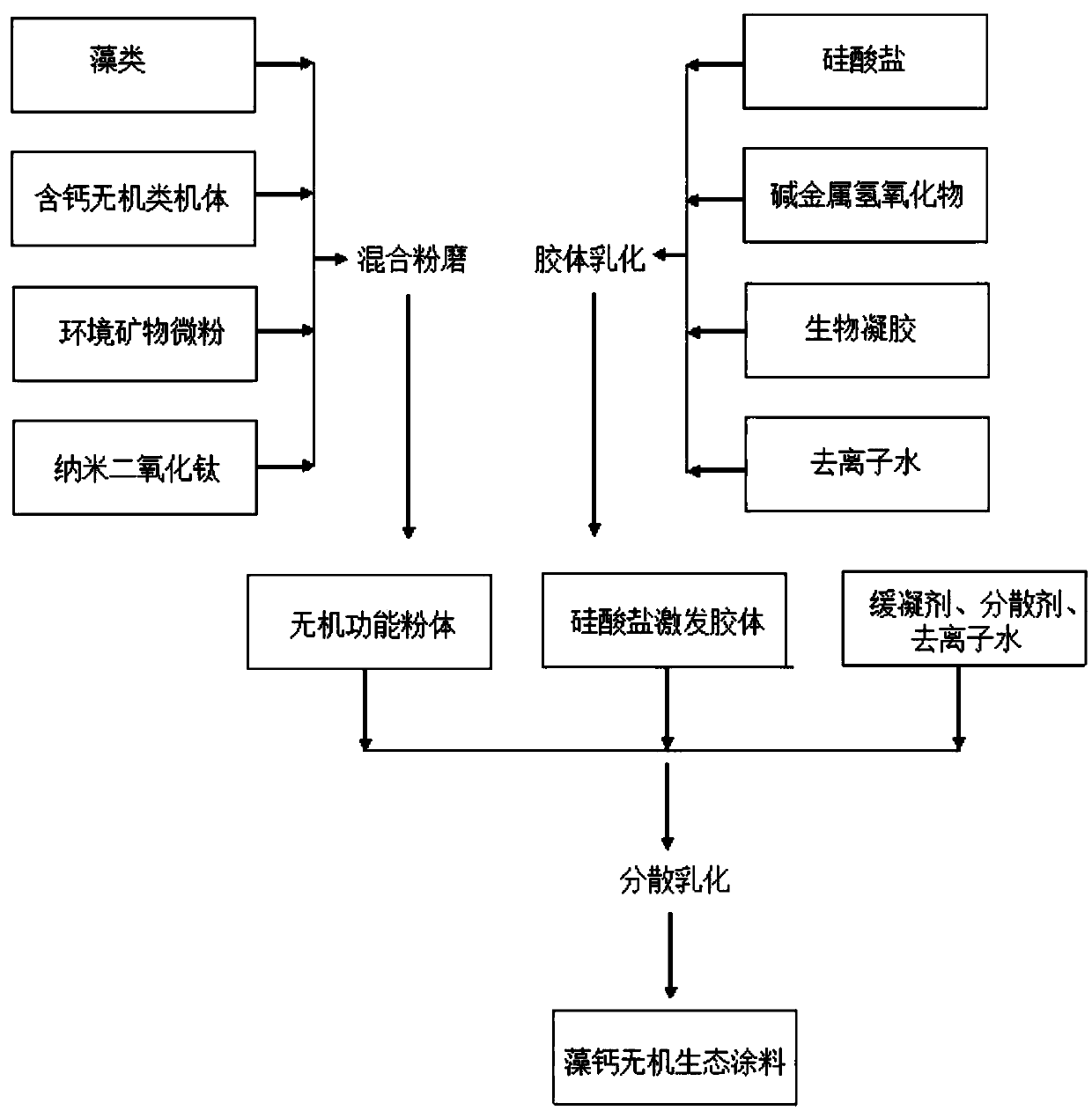

Method used

Image

Examples

Embodiment 1

[0040] 1, a kind of raw material component of calcium algae inorganic ecological paint (substance measurement unit is all by weight percentage):

[0041] (1) Algae: 5.5% of white diatomite, which is loaded with titanium dioxide or bleached, and its particle size is 600 mesh;

[0042] (2) Calcium-containing inorganic matrix: calcium sulfate hemihydrate 18%, shell calcium carbonate 22%, the whiteness of the calcium-containing inorganic matrix is > 85, the calcium oxide content > 40%, and its particle size is 400 mesh;

[0043] (3) Environmental mineral micropowder: 2.4% of negative ion powder, the environmental mineral micropowder is the environmental mineral micropowder after coating and loading treatment with doping elements or transition elements, its whiteness > 78, and particle size is 600 mesh;

[0044] (4) Nano titanium dioxide: 1.5%;

[0045] (5) Silicate stimulating colloid: 10.3%, the preparation method of this silicate stimulating colloid: first mix 34% potassium s...

Embodiment 2

[0058] 1, a kind of raw material component of calcium algae inorganic ecological paint (substance measurement unit is all by weight percentage):

[0059] (1) Algae: 8.0% of white diatomite, which is loaded with titanium dioxide or bleached, and its particle size is 400 mesh;

[0060] (2) Calcium-containing inorganic matrix: 20% of shell calcium carbonate, 20% of shell calcium oxide, the whiteness of the calcium-containing inorganic matrix is >85, the calcium oxide content is >40%, and its particle size is 600 mesh;

[0061] (3) Environmental mineral micropowder: negative ion powder 1.8%, sepiolite 2.4%, the environmental mineral micropowder is the environmental mineral micropowder treated by doping element or transition element coating load, its whiteness > 78, particle size is 400 mesh ;

[0062] (4) Nano titanium dioxide: 1.5%;

[0063] (5) Silicate stimulating colloid: 10.3%, the preparation method of this silicate stimulating colloid: first mix 34% potassium silicate (...

Embodiment 3

[0076] 1, a kind of raw material component of calcium algae inorganic ecological paint (substance measurement unit is all by weight percentage):

[0077](1) Algae: 3.0% of white diatomite, which is loaded with titanium dioxide or bleached, and its particle size is 500 mesh;

[0078] (2) Calcium-containing inorganic matrix: calcium sulfate hemihydrate 6%, shell calcium carbonate 20%, heavy calcium powder 6%, light calcium powder 6%, the whiteness of the calcium-containing inorganic matrix is > 85, and the calcium oxide content > 40%, the particle size is 500 mesh;

[0079] (3) Environmental mineral micropowder: negative ion powder 1.0%, seagullite micropowder 1.0%, attapulgite 1.0%, sepiolite 1.0%, the environmental mineral micropowder is an environmental mineral coated with doping elements or transition elements Micropowder, the whiteness of which is >78, and the particle size is 500 mesh;

[0080] (4) Nano titanium dioxide: 2.0%;

[0081] (5) Silicate stimulating colloid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com