An oil-based drilling fluid fracture-type leakage plugging formula

An oil-based drilling fluid and leakage technology, applied in the direction of drilling compositions, chemical instruments and methods, etc., can solve the problems that have not been well solved, easy to agglomerate, poor dispersion effect, poor fracture plugging and pressure bearing effect, etc. , to achieve the effect of improving the success rate of plugging, high compressive strength and avoiding agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

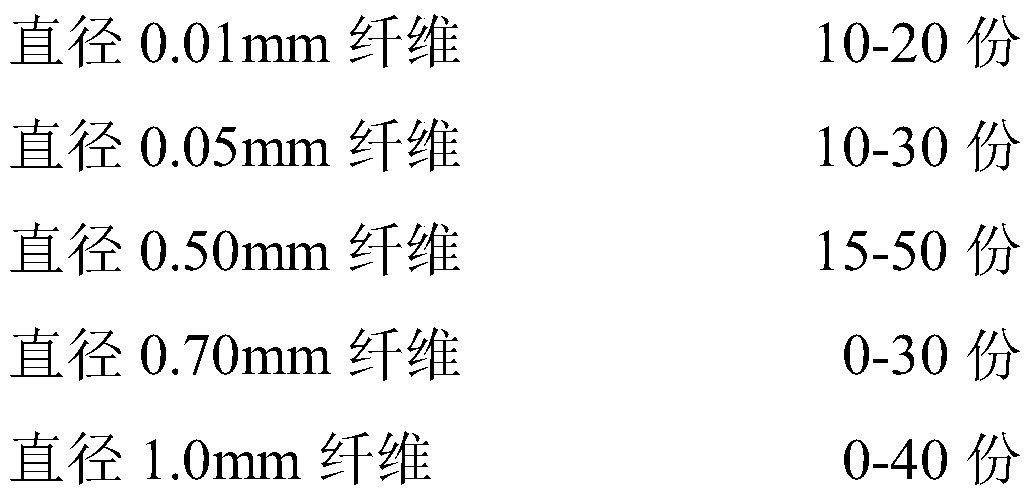

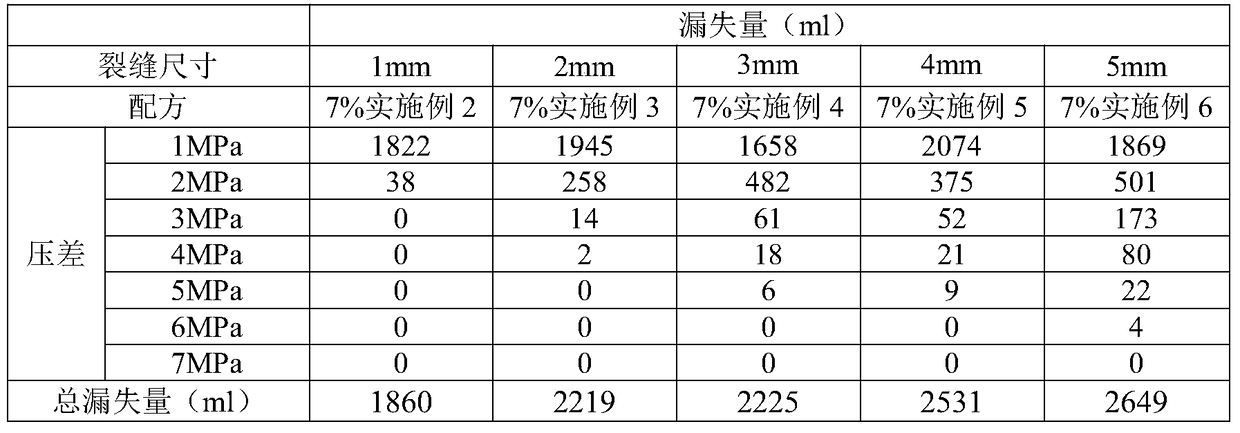

[0021] This embodiment provides a drilling fluid fracture-type leakage plugging formula, including A component and B component, the A component is composed of fiber materials with a diameter of 0.01 mm to 1.00 mm and a length of 0.50 cm to 10.00 cm. The B component is composed of different lipophilic rigid particle materials.

[0022] The plugging principle of the oil-based drilling fluid fracture type leakage plugging formula of the present invention is to use a series of fiber materials (component A) for oil-based drilling fluid plugging to form a rapid water loss sealing layer in the oil-based drilling fluid leakage fracture channel, and then The lipophilic rigid granular material (component B) enters the plugging layer to block and restrict penetration. The two components of A and B act synergistically to achieve the effect of plugging and controlling leakage. The oil-based drilling fluid fracture-type leakage plugging formula can significantly improve the success rate of ...

Embodiment 2

[0024] On the basis of Example 1, put 20 parts of fibers with a diameter of 0.01 mm, 30 parts of fibers with a diameter of 0.05 mm, and 50 parts of fibers with a diameter of 0.50 mm, and put them in a mixing device for uniform mixing to obtain the oil-based drilling fluid fracture-type leakage plugging Formulation A component.

[0025] The fiber material used in this embodiment is one or more of modified wood fibers, polypropylene fibers, multi-block polyurethane elastic fibers, and polybutylene terephthalate fibers.

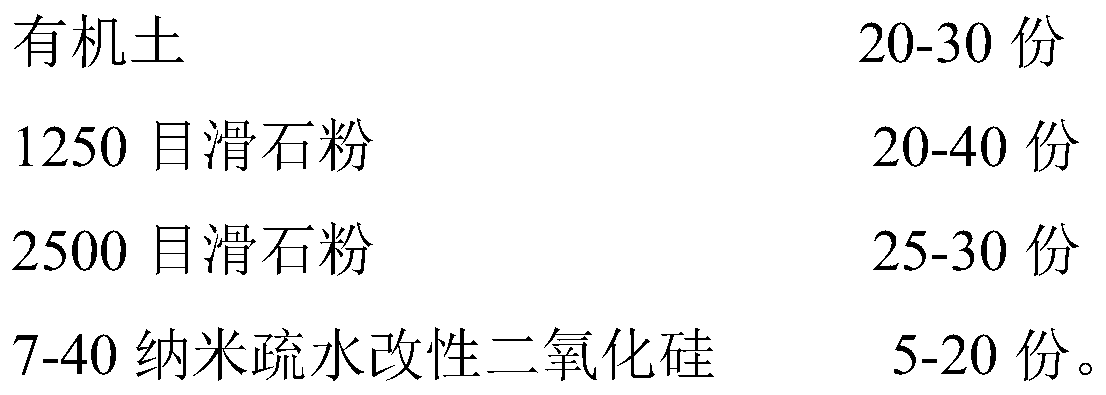

[0026] Put 30 parts of organic soil, 20 parts of 1250 mesh talc powder, 30 parts of 2500 mesh talc powder, 20 parts of 7-40 nanometer hydrophobic modified silica, and mix them uniformly in the mixing equipment to get the oil-based drilling fluid fracture type Leakage plugging formula component B.

Embodiment 3

[0028] Put 15 parts of fibers with a diameter of 0.01mm, 20 parts of fibers with a diameter of 0.05mm, 35 parts of fibers with a diameter of 0.50mm, and 30 parts of fibers with a diameter of 0.70mm, and put them in a mixing device for uniform mixing to obtain the oil-based drilling fluid fracture-type leakage plugging formula A component. The fiber used is one or more of modified wood fiber, polypropylene fiber, multi-block polyurethane elastic fiber and polybutylene terephthalate fiber.

[0029] Put 30 parts of organic soil, 20 parts of 1250 mesh talc powder, 30 parts of 2500 mesh talc powder, 20 parts of 7-40 nanometer hydrophobic modified silica, and mix them uniformly in the mixing equipment to get the oil-based drilling fluid fracture type Leakage plugging formula component B.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com