Oil base drilling fluid fracture leakage stoppage formula

An oil-based drilling fluid and leakage technology, applied in the directions of drilling compositions, chemical instruments and methods, etc., can solve the problems of poor crack plugging and pressure-bearing effect, not well solved, easy agglomeration and poor dispersion effect, etc. , to achieve the effect of improving the success rate of plugging, high compressive strength and good dispersion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

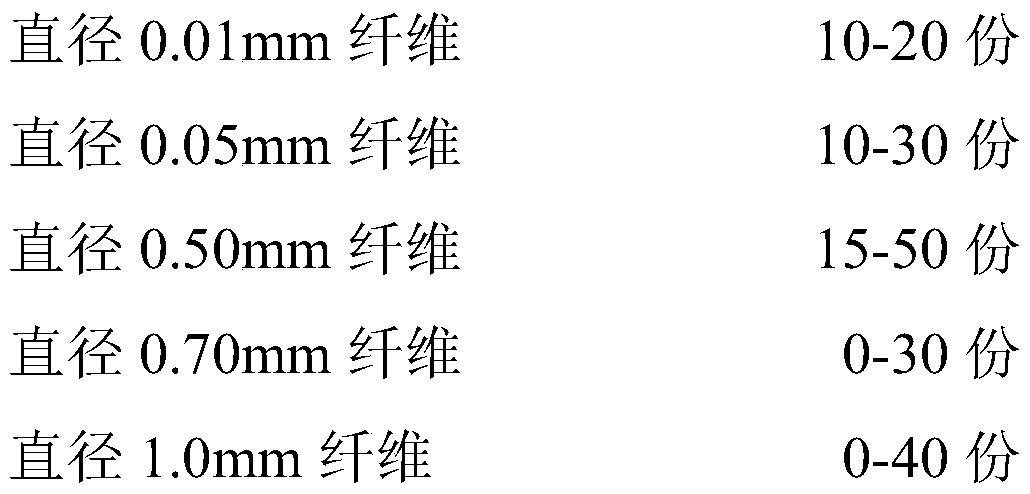

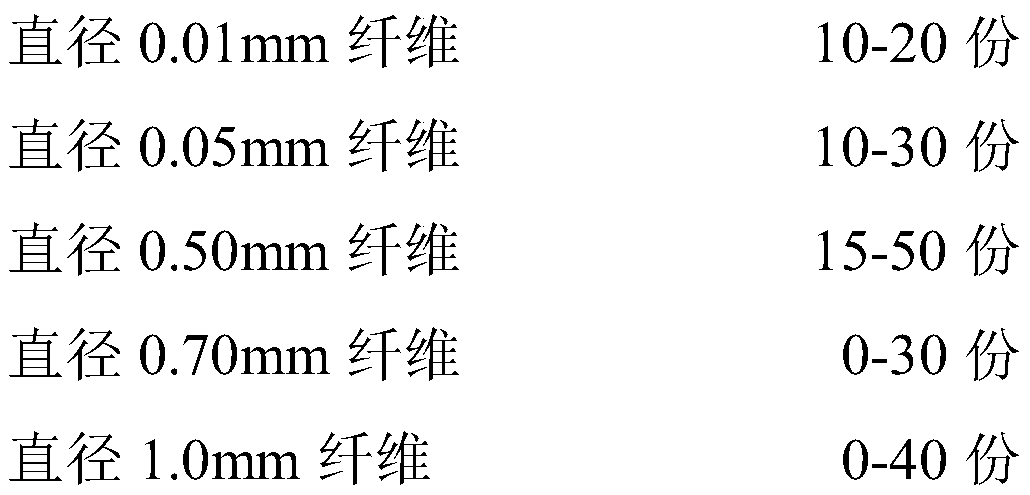

[0021] This embodiment provides a drilling fluid fracture-type leakage plugging formula, including A component and B component, the A component is composed of fiber materials with a diameter of 0.01 mm to 1.00 mm and a length of 0.50 cm to 10.00 cm. The B component is composed of different lipophilic rigid particle materials.

[0022] The plugging principle of the oil-based drilling fluid fracture type leakage plugging formula of the present invention is to use a series of fiber materials (component A) for oil-based drilling fluid plugging to form a rapid water loss sealing layer in the oil-based drilling fluid leakage fracture channel, and then The lipophilic rigid granular material (component B) enters the plugging layer to block and restrict penetration. The two components of A and B act synergistically to achieve the effect of plugging and controlling leakage. The oil-based drilling fluid fracture-type leakage plugging formula can significantly improve the success rate of ...

Embodiment 2

[0024] On the basis of Example 1, put 20 parts of fibers with a diameter of 0.01 mm, 30 parts of fibers with a diameter of 0.05 mm, and 50 parts of fibers with a diameter of 0.50 mm, and put them in a mixing device for uniform mixing to obtain the oil-based drilling fluid fracture-type leakage plugging Formulation A component.

[0025] The fiber material used in this embodiment is one or more of modified wood fibers, polypropylene fibers, multi-block polyurethane elastic fibers, and polybutylene terephthalate fibers.

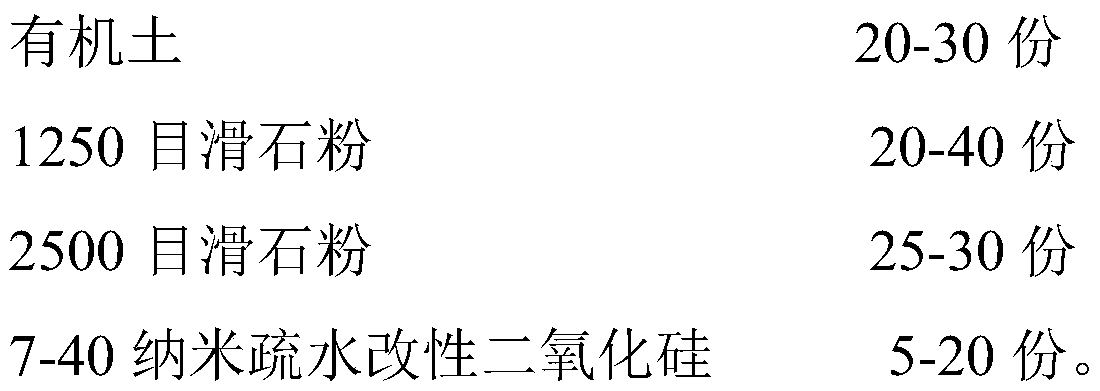

[0026] Put 30 parts of organic soil, 20 parts of 1250 mesh talc powder, 30 parts of 2500 mesh talc powder, 20 parts of 7-40 nanometer hydrophobic modified silica, and mix them uniformly in the mixing equipment to get the oil-based drilling fluid fracture type Leakage plugging formula component B.

Embodiment 3

[0028] Put 15 parts of fibers with a diameter of 0.01mm, 20 parts of fibers with a diameter of 0.05mm, 35 parts of fibers with a diameter of 0.50mm, and 30 parts of fibers with a diameter of 0.70mm, and put them in a mixing device for uniform mixing to obtain the oil-based drilling fluid fracture-type leakage plugging formula A component. The fiber used is one or more of modified wood fiber, polypropylene fiber, multi-block polyurethane elastic fiber and polybutylene terephthalate fiber.

[0029] Put 30 parts of organic soil, 20 parts of 1250 mesh talc powder, 30 parts of 2500 mesh talc powder, 20 parts of 7-40 nanometer hydrophobic modified silica, and mix them uniformly in the mixing equipment to get the oil-based drilling fluid fracture type Leakage plugging formula component B.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com