Preparation method for lubricating oil pour point depressing type viscosity index improver

A technology of viscosity index and lubricating oil, which is applied in the direction of lubricating compositions and the petroleum industry, can solve problems such as difficulties, low product quality, and different process conditions, and achieve good high-temperature oxidation stability, good low-temperature fluidity, and obvious drop coagulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

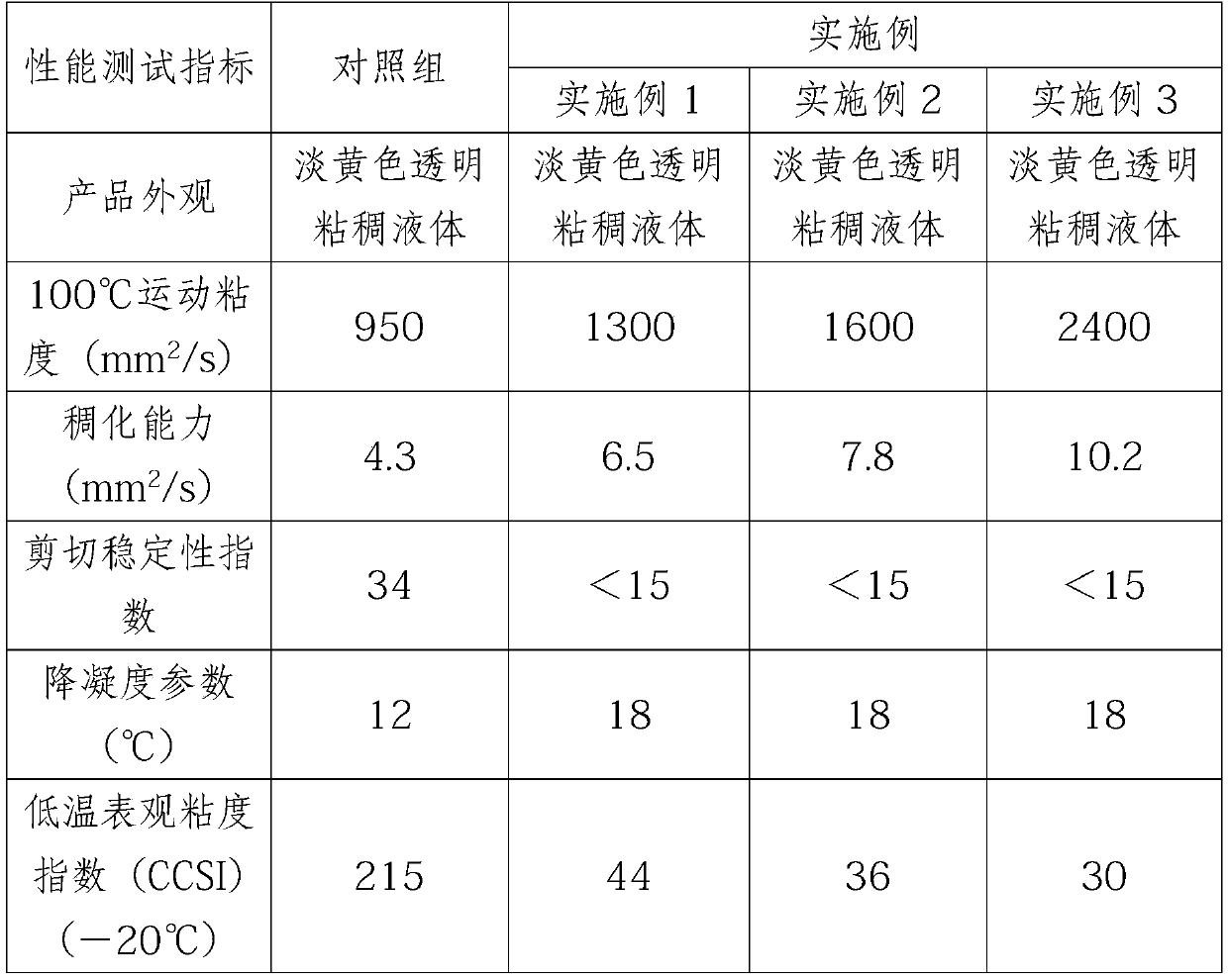

Examples

preparation example Construction

[0044] In the preparation method of the present invention, after the grafting process, the product is exhausted and the viscosity is adjusted. Due to the two processes of vacuum exhaust and hydrogenated base oil viscosity adjustment, the color, fluidity and oxidation stability of the product are improved. more excellent.

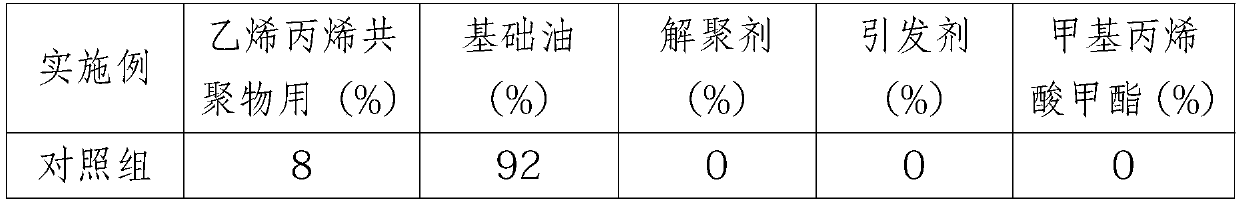

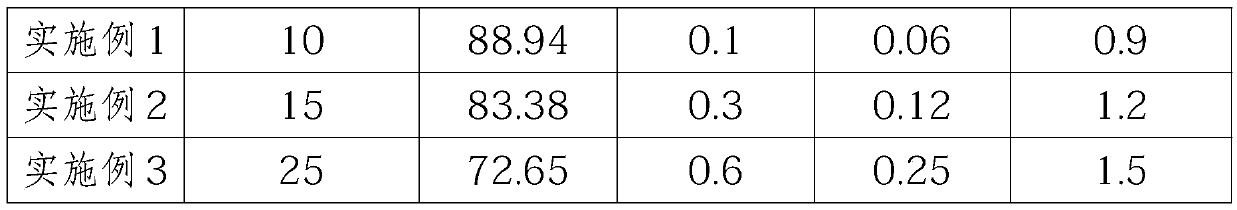

[0045] Table 1 shows the amount of raw materials used in the control group and Examples 1 to 3 of the present invention.

[0046] The raw material consumption table of table 1 embodiment 1~embodiment 3

[0047]

[0048]

[0049] control group

[0050] The lubricating oil viscosity index improver prepared according to the preparation method of the prior art and according to the raw material ratio in the above Table 1 was used as a control product.

Embodiment 1

[0052] Adopt the preparation method provided by the present invention and the method for preparing lubricating oil depressing type viscosity index improver according to the raw material ratio in above-mentioned table 1 is:

[0053] (1) Soaking: Add 44.47% hydrogenated base oil into the reaction kettle, and start stirring. At the same time, cut the 10% ethylene propylene copolymer solid dry glue into pieces of about 5 cm. Put the block-shaped ethylene-propylene copolymer into the reactor, and soak the ethylene-propylene copolymer in the hydrogenated base oil for 0.5-1 hour.

[0054] (2) Dissolving: After soaking, nitrogen gas is passed into the reaction kettle, and the pressure of nitrogen gas is 0.2-0.4 MPa. Heating to 130°C. Keep the reaction system at 130°C for 2-3 hours to dissolve the ethylene-propylene copolymer.

[0055] (3) Depolymerization: After the dissolution process is finished, add 0.1% benzoyl peroxide or lauroyl peroxide depolymerization agent into the reacti...

Embodiment 2

[0059] Adopt the preparation method provided by the present invention and the method for preparing lubricating oil depressing type viscosity index improver according to the raw material ratio in above-mentioned table 1 is:

[0060] (1) Soaking: Add 41.69% hydrogenated base oil into the reaction kettle, and start stirring. Simultaneously, cut the 15% ethylene propylene copolymer solid dry glue into pieces of about 5 cm. Put the block-shaped ethylene-propylene copolymer into the reactor, and soak the ethylene-propylene copolymer in the hydrogenated base oil for 0.5-1 hour.

[0061] (2) Dissolving: After soaking, nitrogen gas is passed into the reaction kettle, and the pressure of nitrogen gas is 0.2-0.4 MPa. Heating to 130°C. Keep the reaction system at 130°C for 2-3 hours to dissolve the ethylene-propylene copolymer.

[0062] (3) Depolymerization: After the dissolution process is finished, add 0.3% benzoyl peroxide or lauroyl peroxide depolymerization agent into the reaction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com