Method for extracting high-purity crambe abyssinica seed oil and cream containing crambe abyssinica seed oil

An extraction method and high-purity technology, applied in the field of natural product extraction, can solve the problems of long extraction time, large solvent residue, and large solvent volatilization, and achieve shortening extraction time, improving extraction efficiency, and rapid and uniform temperature rise Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

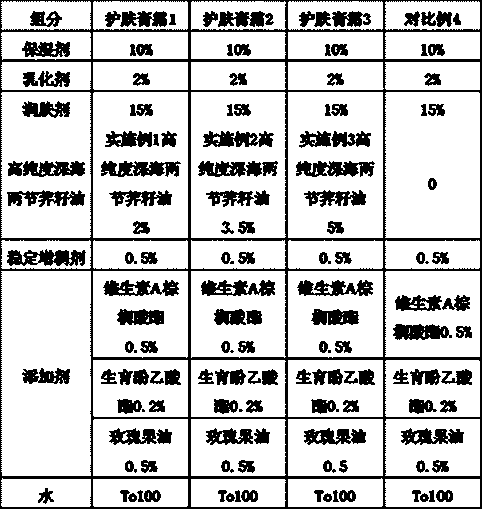

Examples

Embodiment 1

[0027] A method for extracting high-purity deep-sea chestnut seed oil, comprising the steps of:

[0028] (1) Accurately weigh a certain amount of deep-sea chestnut seeds, place them in a configuration container, and add chloroform extractant for extraction. The amount of chloroform used is 10 times the weight of deep-sea chestnut seeds. Microwave frequency 3×10 5 Hz, the microwave power is 600W;

[0029] (2) The obtained mixture is filtered, and the obtained filtrate is subjected to rotary separation on a rotary evaporator, and after removing chloroform, the residue is deep-sea two-sectioned chestnut seed crude oil;

[0030] (3) Put the obtained deep-sea two-sectioned chestnut seed crude oil into a fixed container, add a certain amount of sodium hydroxide when heated to a certain temperature, and continue to heat up to about 110°C. At this time, a large number of bubbles are generated, and keep warm until the bubbles basically disappear. , stop heating, wash with warm water ...

Embodiment 2

[0034] A method for extracting high-purity deep-sea chestnut seed oil, comprising the steps of:

[0035] (1) Accurately weigh a certain amount of deep-sea chestnut seeds, put them in a configuration container, add dichloromethane extractant for extraction, the amount of dichloromethane used is 12 times the weight of deep-sea chestnut seeds, microwave frequency 3×10 6 Hz, the microwave power is 700W;

[0036] (2) The obtained mixture is filtered, and the obtained filtrate is subjected to rotary separation on a rotary evaporator, and the residue after removing dichloromethane is crude oil of deep-sea catharsis oil;

[0037] (3) Put the crude oil of deep-sea two-sectioned chestnut seed oil into a fixed container, add a certain amount of sodium hydroxide when heated to a certain temperature, and continue to heat up to about 110°C. At this time, a large number of bubbles are generated, keep warm until the bubbles disappear, stop heating, wash with warm water until neutral;

[00...

Embodiment 3

[0041] A method for extracting high-purity deep-sea chestnut seed oil, comprising the steps of:

[0042] (1) Accurately weigh a certain amount of deep-sea chestnut seeds, put them in a configuration container, add n-hexane extractant for extraction, the amount of n-hexane used is 14 times the weight of deep-sea chestnut seeds, and the microwave frequency is 3 ×10 6 Hz, the microwave power is 800W;

[0043] (2) The obtained mixture is filtered, and the obtained filtrate is subjected to rotary separation on a rotary evaporator, and after removing n-hexane, the residue is crude oil of deep-sea chestnut seed oil;

[0044] (3) Put the crude oil of deep-sea two-sectioned chestnut seed oil into a fixed container, add a certain amount of sodium hydroxide when heated to a certain temperature, and continue to heat up to about 110°C. At this time, a large number of bubbles are generated, keep warm until the bubbles disappear, stop heating, wash with warm water until neutral;

[0045] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com