Regeneration technology of marine vanadium-titanium catalyst for SCR denitrification

A catalyst and denitration technology, applied in the direction of catalyst regeneration/reactivation, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problems of inappropriate cleaning and regeneration technology of denitration catalysts in power stations, loss of active substances, catalyst pollution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

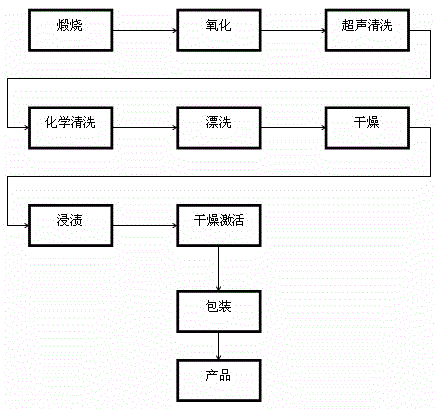

[0036] The present invention will be further explained below in conjunction with the drawings in the specification:

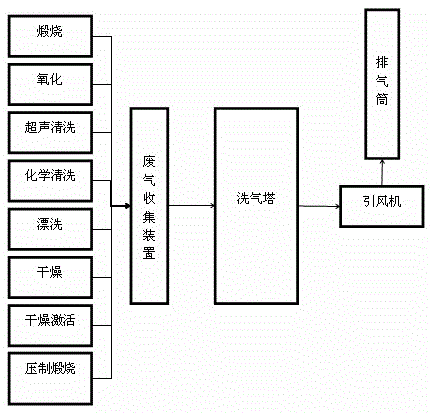

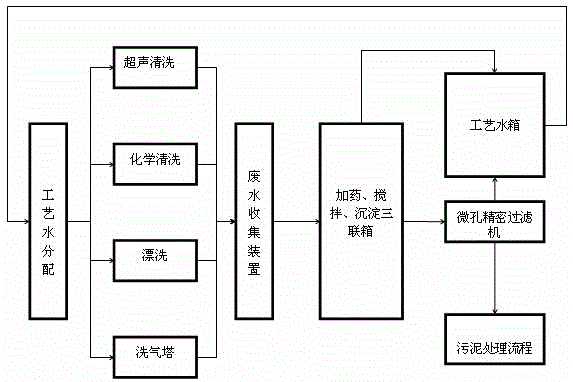

[0037] A vanadium-titanium catalyst regeneration process for marine SCR denitrification includes main process flow, exhaust gas treatment process, waste water treatment process and sludge treatment process. The main process flow process steps are as follows:

[0038] a. Use a calciner to calcinate the deactivated catalyst (catalyst that has lost its activity). The temperature is controlled at 300-600°C, the time is controlled at 10-30 minutes, and the heating rate is 2-10°C / min to carbonize grease pollutants;

[0039] b. The calcined catalyst enters the oxidation furnace for oxidation treatment. The ozone-air mixed gas with a concentration of 20-300mg / l is passed into the oxidation furnace. The temperature of the ozone-air mixed gas is controlled at 50-300℃, and the oxidation time of the oxidation furnace Control within 10-120min, and control the ozone-air mixed gas f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com