Preparing method of cube platinum ruthenium core-shell nanocrystalline and product of preparing method

A technology of cubes and nanocrystals, applied in the field of nanomaterials, can solve the problems of complex preparation methods, uneven size and morphology of products, etc., and achieve the effects of simple reagents, low cost and good dispersibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] (1) Weigh 9.84mg chloroplatinic acid (H 2 PtCl 6 ), 14.34mg ruthenium acetylacetonate (Ru(acac) 3 ), 110mg tri-n-octylphosphine oxide (TOPO), add 4mL N, N-dimethylformamide (DMF) and 4mL oleylamine (OAm) simultaneously; / L, 0.0045mol / L and 0.0356mol / L;

[0025] (2) Stir the mixed solution prepared in (1) for more than 30 minutes to fully dissolve;

[0026] (3) Place the mixed solution obtained in (2) in a heater, heat to 220°C while stirring, and react for 180 minutes;

[0027] (4) Centrifuge the product obtained in (3) at a speed of 3,000 to 5,000 rpm for 5 minutes, discard the supernatant, remove excess OAm and TOPO, and centrifuge for 3 to 5 times;

[0028] (5) ultrasonically disperse the precipitate obtained in (4) in cyclohexane, and store at room temperature.

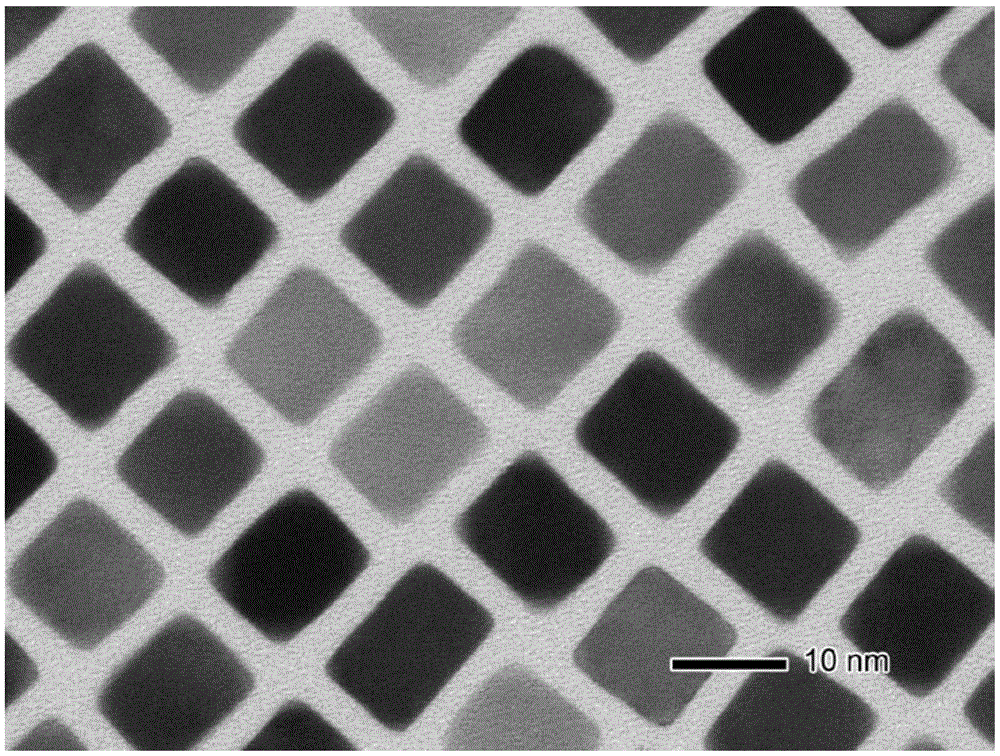

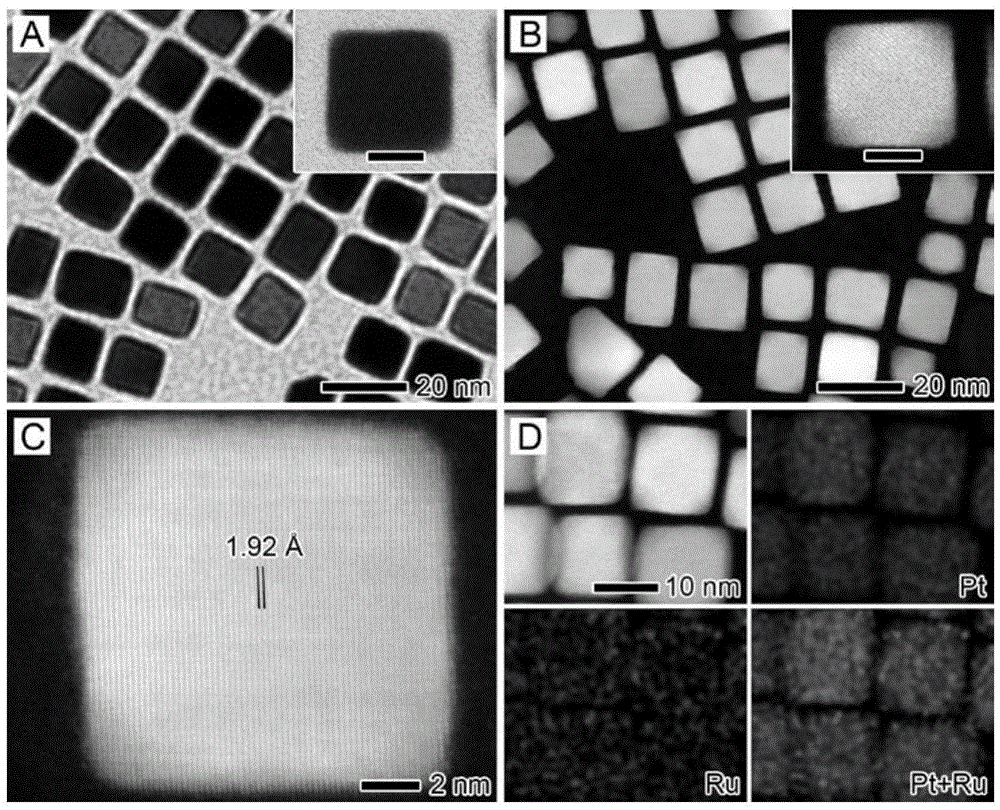

[0029] figure 1 It is a transmission electron microscope (TEM) image at 180,000 magnifications; figure 2 Part A is a transmission electron microscope image at 100,000 magnification; part B is a scan...

Embodiment 2

[0031] (1) Weigh 4.92mg chloroplatinic acid (H2PtCl6), 19.12mg ruthenium acetylacetonate (Ru(acac) 3 ), 110mg tri-n-octylphosphine oxide (TOPO), add 4mL N, N-dimethylformamide (DMF) and 4mL oleylamine (OAm) simultaneously; / L, 0.006mol / L and 0.0356mol / L;

[0032] (2) Stir the mixed solution prepared in (1) for more than 30 minutes to fully dissolve;

[0033] (3) Place the mixed solution obtained in (2) in a heater, heat to 220°C while stirring, and react for 180 minutes;

[0034] (4) Centrifuge the product obtained in (3) at a speed of 3,000 to 5,000 rpm for 5 minutes, discard the supernatant, remove excess OAm and TOPO, and centrifuge for 3 to 5 times;

[0035] (5) ultrasonically disperse the precipitate obtained in (4) in cyclohexane, and store at room temperature. The result obtained is similar to Example 1.

Embodiment 3

[0037] (1) Weigh 14.76mg of chloroplatinic acid (H 2 PtCl 6 ), 9.56mg ruthenium acetylacetonate (Ru(acac) 3), 110mg tri-n-octylphosphine oxide (TOPO), add 4mL N, N-dimethylformamide (DMF) and 4mL oleylamine (OAm) simultaneously; / L, 0.003mol / L and 0.0356mol / L;

[0038] (2) Stir the mixed solution prepared in (1) for more than 30 minutes to fully dissolve;

[0039] (3) Place the mixed solution obtained in (2) in a heater, heat to 220°C while stirring, and react for 180 minutes;

[0040] (4) Centrifuge the product obtained in (3) at a speed of 3,000 to 5,000 rpm for 5 minutes, discard the supernatant, remove excess OAm and TOPO, and centrifuge for 3 to 5 times;

[0041] (5) ultrasonically disperse the precipitate obtained in (4) in cyclohexane, and store at room temperature. The result obtained is similar to Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com