Nickel base 625 welding wire of single-surface welding and double-surface molding argon arc backing welding without argon filling on back surface

A technology of single-sided welding, double-sided welding, and bottoming welding, which is applied to welding media, welding equipment, welding/cutting media/materials, etc. The welding seam is beautiful and the welding process is excellent.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

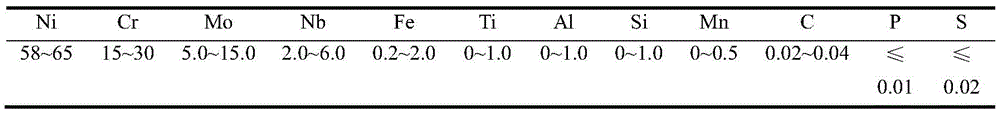

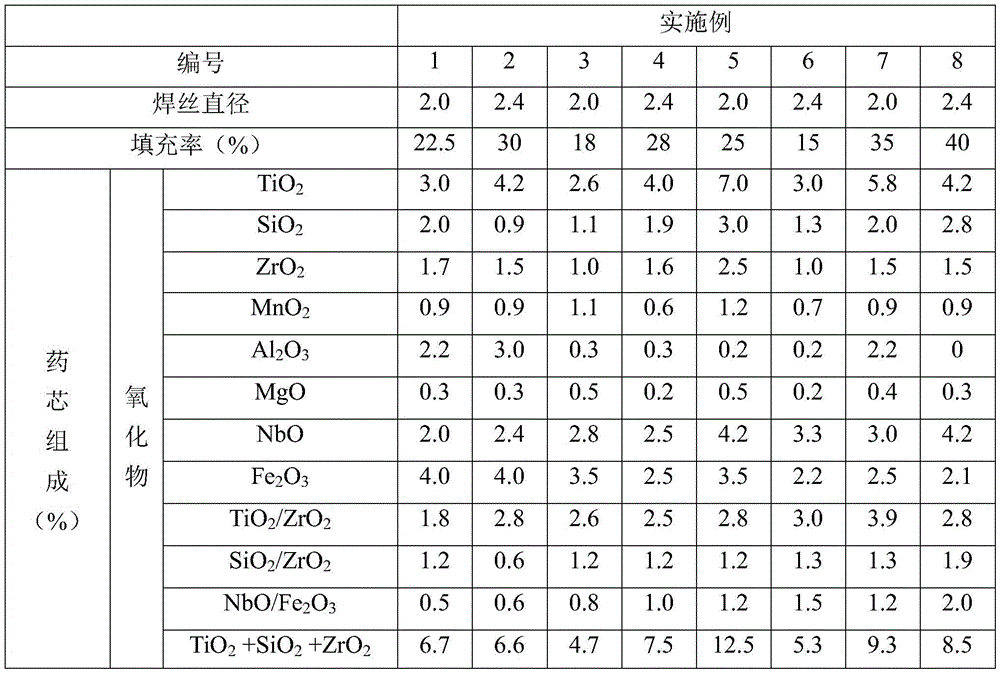

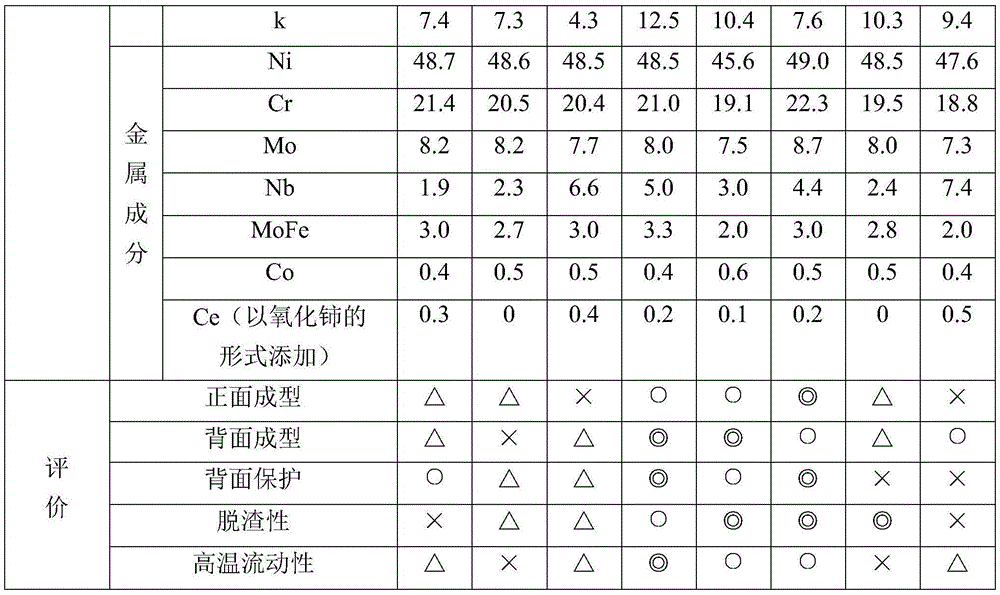

[0037] The ENiCrMo3T nickel-based 625 welding wire used for welding nickel-based alloy pipes uses 10×0.4mm nickel strip 625 as the outer skin (the composition is shown in Table 1), the filling rate is 22.5%, and the wire diameter is 2.0mm. The chemical composition (weight %) of drug core is: TiO 2 : 3.0%, SiO 2 : 2.0%, ZrO 2 : 1.7%, MnO 2 : 0.9%, Al 2 o 3 : 2.2%, MgO: 0.3%, NbO: 2.0%; Fe2 o 3 : 4.0%, Cr: 21.4%, Mo: 8.2%, Nb: 1.9%, MoFe: 3.0%, Co: 0.4%, Ce: 0.3%, and the balance is nickel powder. The front uses pure Ar as the shielding gas, the gas flow rate is 15-20L / min, the DC reverse connection method is adopted, and the welding current is 90-110A.

Embodiment 2

[0039] The ENiCrMo3T nickel-based 625 welding wire used for welding nickel-based alloy pipes uses 12×0.5mm nickel strip 625 as the outer skin (the composition is shown in Table 1), the filling rate is 30%, and the welding wire diameter is 2.4mm. The chemical composition (weight %) of drug core is: TiO 2 : 4.2%, SiO 2 : 0.9%, ZrO 2 : 1.5%, MnO 2 : 0.9%, Al 2 o 3 : 3.0%, MgO: 0.3%, NbO: 2.4%; Fe 2 o 3 : 4.0%, Cr: 20.5%, Mo: 8.2%, Nb: 2.3%, MoFe: 2.7%, Co: 0.5%, and the balance is nickel powder. The front uses pure Ar as the shielding gas, the gas flow rate is 15-20L / min, the DC reverse connection method is adopted, and the welding current is 120-150A.

Embodiment 3

[0041] The ENiCrMo3T nickel-based 625 welding wire used for welding nickel-based alloy pipes uses 8×0.3mm nickel strip 625 as the sheath (the composition is shown in Table 1), the filling rate is 18%, and the wire diameter is 2.0mm. The chemical composition (weight %) of drug core is: TiO 2 : 2.6%, SiO 2 : 1.1%, ZrO 2 : 1.0%, MnO 2 : 1.1%, Al 2 o 3 : 0.3%, MgO: 0.5%, NbO: 2.8%; Fe 2 o 3 : 3.5%, Cr: 20.4%, Mo: 7.7%, Nb: 6.6%, MoFe: 3.0%, Co: 0.5%, Ce: 0.4%, and the balance is nickel powder. The front uses pure Ar as the shielding gas, the gas flow rate is 15-20L / min, the DC reverse connection method is adopted, and the welding current is 90-110A.

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com