A kind of preparation method of rubber-plastic composition

A composition and rubber-plastic technology, which is applied in the field of rubber-plastic composition preparation, can solve the problems of low inflation and poor mechanical properties of thermoplastic films, and achieve the effects of good elasticity, uniform appearance, and improved inflation ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

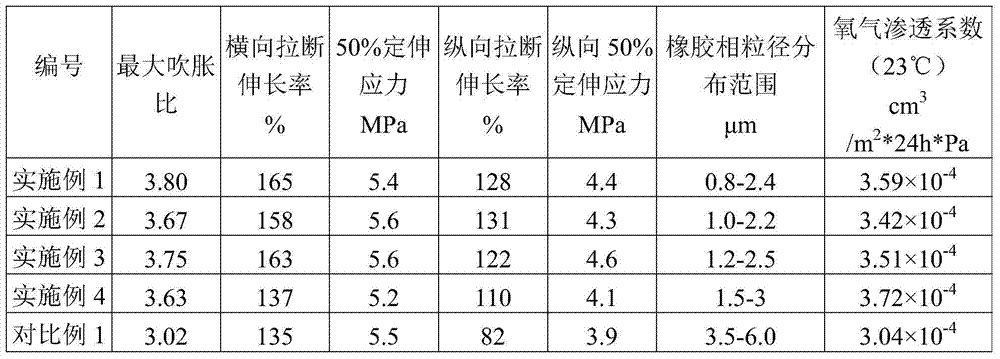

Examples

preparation example Construction

[0016] The invention provides a method for preparing a rubber-plastic composition, the method comprising:

[0017] (1) Carry out banburying and granulation with halogenated butyl rubber, low molecular weight nylon and activator to obtain modified rubber;

[0018] (2) The modified rubber obtained in step (1), copolymerized nylon, long carbon chain nylon, low-density polyethylene, vulcanizing agent and vulcanization accelerator are blended, heated and melted and extruded to granulate,

[0019] Wherein, the weight average molecular weight of the low-molecular-weight nylon is 5000-25000 Daltons, the melt mass flow rate of the low-density polyethylene measured according to GB / T3682-2000 is 0.1-10g / 10min, and the low-density polyethylene The density of ethylene is 0.915-0.925g / cm 3 .

[0020] In the present invention, dynamic vulcanization refers to the blending of non-crosslinked rubber and thermoplastic polymers (such as resins) that cannot be vulcanized under the action of high...

preparation example 1

[0076] This preparation example is used for the rubber and plastic composition provided by the present invention and its preparation method.

[0077] (1) 100 parts by weight of bromobutyl rubber, 8 parts by weight of low molecular weight nylon, 1 part by weight of stearic acid, 6 parts by weight of epoxy soybean oil, 3 parts by weight of tackifier HY-203 (Shanxi Chemical Industry Research Institute), 3 parts by weight of leveling agent 40MS (Germany S.S company) were put into the internal mixer for initial mixing, the speed of the rotor was 60rpm, and banburying was carried out at 80°C, the banburying pressure was 0.3MPa, and the banburying The time is 3.5min, and then the banbury film obtained is granulated in a rubber granulator to obtain modified rubber particles;

[0078] (2) The modified rubber particles obtained in step (1), 2 parts by weight of zinc oxide, 0.8 parts by weight of insoluble sulfur, 2 parts by weight of accelerator DM (Tianjin Labo Auxiliary Co., Ltd.), 30...

preparation example 2

[0080] This preparation example is used for the rubber and plastic composition provided by the present invention and its preparation method.

[0081] (1) 100 parts by weight of bromobutyl rubber, 10 parts by weight of low molecular weight nylon, 2 parts by weight of stearic acid, 7.5 parts by weight of epoxy soybean oil, 3.5 parts by weight of tackifier HY-203 (Shanxi Chemical Industry Research Institute), 3.5 parts by weight of leveling agent 40MS (German S.S company) were put into the internal mixer for initial mixing, the speed of the rotor was 40rpm, and banburying was carried out at 100°C, the banburying pressure was 0.2MPa, and banburying The time is 4min, then the banbury rubber sheet obtained is granulated in a rubber granulator to obtain modified rubber particles;

[0082] (2) The modified rubber particle that step (1) obtains, the zinc oxide of 3 parts by weight, the insoluble sulfur of 0.5 part by weight, the accelerator DM (Tianjin Labo Auxiliary Co., Ltd.) of 1.0 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com