Preparation and treatment process of Mg-Gd-Y-Zr alloy

A treatment process and alloy technology, which is applied in the field of Mg-Gd-Y-Zr alloy preparation and its treatment process, to achieve the effect of obvious changes in mechanical properties such as hardness and strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

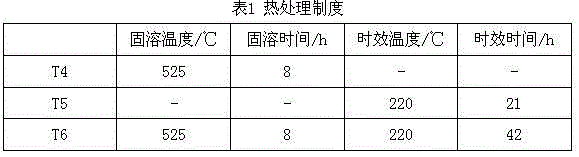

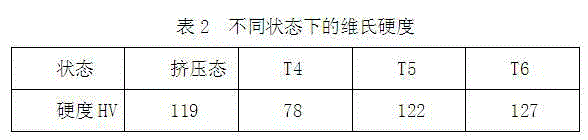

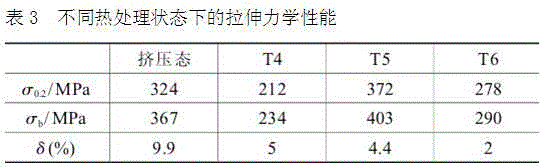

[0008] Mg-12Gd-3Y-0.6Zr (mass fraction, the same below) alloy was prepared by ingot metallurgy. The experimental materials are industrial pure magnesium, magnesium-gadolinium (30.47%Gd) master alloy, magnesium-yttrium (31.72%Y) master alloy and magnesium-zirconium (30.16%Zr) master alloy. Melting at 730-750°C, protected by CO2+SF6 mixed gas. Cast into a round ingot of quasi-180mm, after homogenized annealing at 530°C for 24 hours, then extrude at 450°C with an extrusion ratio of 16:1. The extruded alloy rods are subjected to three heat treatments: solid solution (T4), aging (T5) and solid solution + aging (T6). The determination of the heat treatment system refers to the magnesium alloy phase diagram, see Table 1 for details. During solid solution treatment, warm water at 70-80°C is used for cooling. HVS-1000 digital display microhardness tester is used to measure the hardness of alloy samples in various states, the load is 4.9N, and the load is 15s. The hardness test value ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com