Large structure dynamic optimization design method based on structural decomposition

A large-scale component, dynamic optimization technology, applied in the direction of constraint-based CAD, design optimization/simulation, calculation, etc., can solve problems such as unsatisfactory control effect, structural deformation, equipment structure damage, etc., to achieve the effect of reliable technical support

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

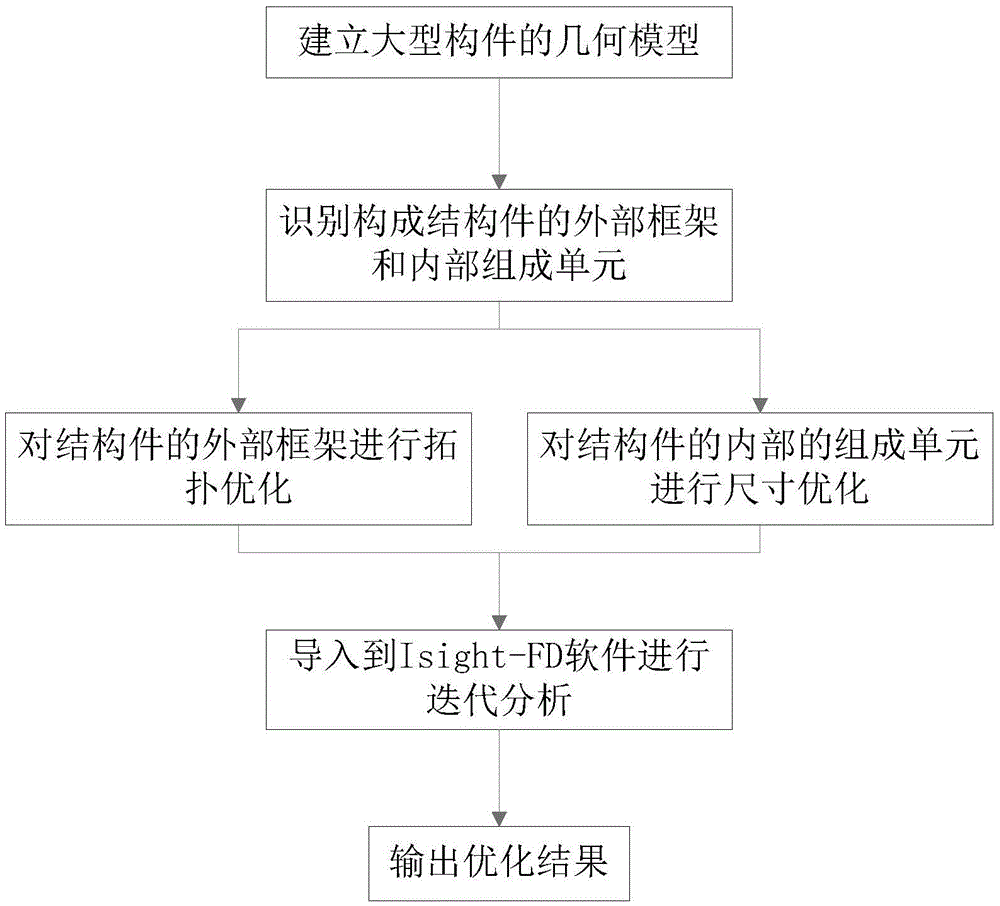

[0044] Such as figure 1 Shown is the flow chart of the method of the present invention.

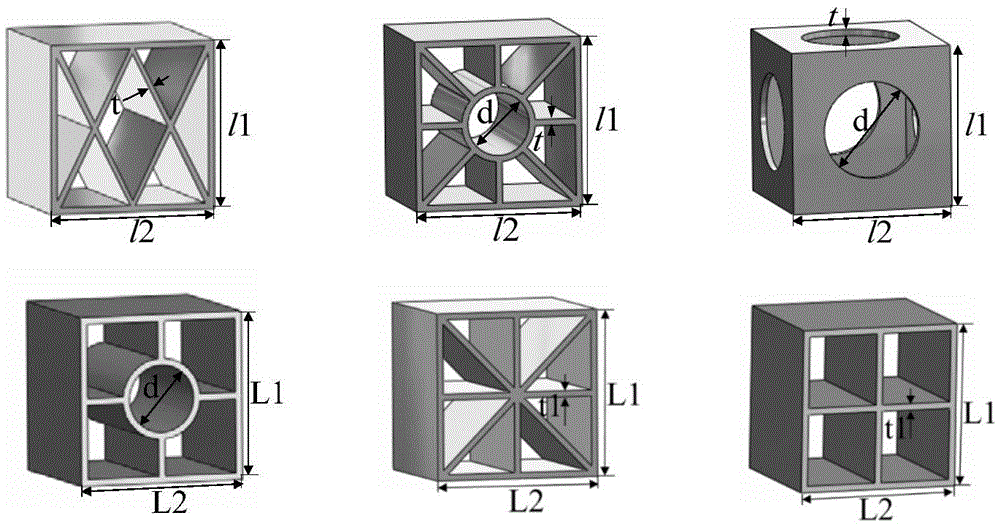

[0045] Step 1. Firstly, use 3D modeling software to establish the geometric model of complex parts; identify the main frame size variables that make up the structural parts and the basic style and size variables that make up the internal units. The specific identification method is: define the external outline size of the structural member as frame size variables, such as length, width, height and cross-sectional area. Fill the structures that make up the interior of large parts with ribs (basic units) of different styles, for example: cross bars, rice bars, oblique bars, and sun bars, etc., see figure 1 . In addition, variables are defined for the dimensions of different parts of each rib, such as wall thickness, diameter, and rib size. The style and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com