A kind of composite flexible nanogenerator and preparation method thereof

A nanogenerator and flexible technology, applied in the manufacture/assembly of piezoelectric/electrostrictive devices, circuits, electrical components, etc., can solve the problems of large space occupation, low energy conversion rate, time limit, etc., and achieve effective area Improvement, simple preparation process, and optimized output performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

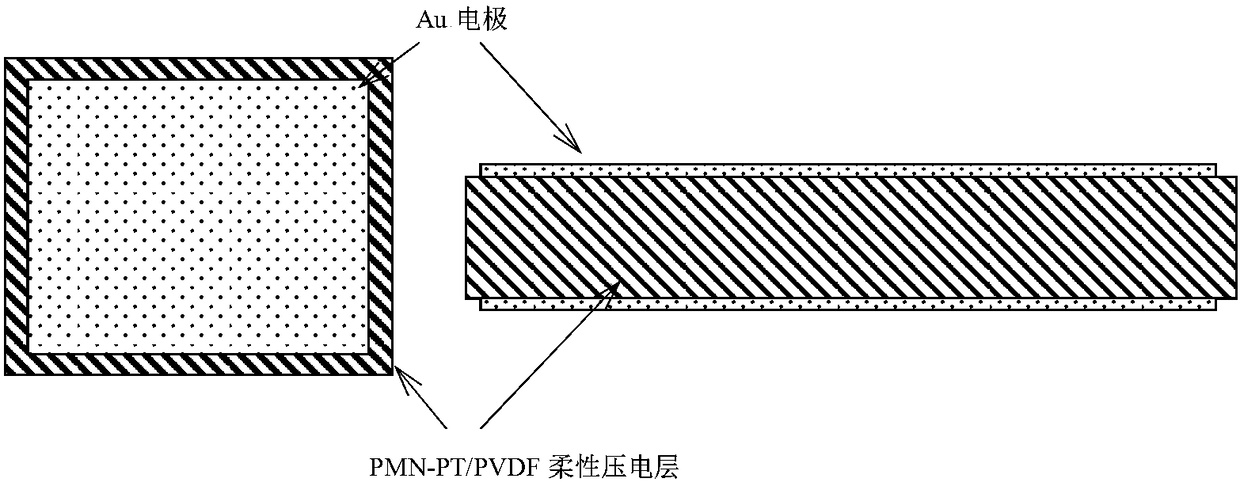

[0024] Weigh PMN-PT single crystal nanowires and PVDF powder according to the ratio of 10PMN-PT / 90PVDF, dissolve the two raw materials in 20ml of DMA, and alternately act on magnetic stirring and ultrasonic dispersion for 4 hours until the solution is evenly mixed; Pour the solution into a petri dish with a diameter of 10 cm and place it horizontally for 10 minutes to spread the solution evenly on the petri dish; keep the solution in a horizontal state and move it into an oven, and dry it at 60°C for 12 hours to completely evaporate the liquid; remove the obtained film from the culture Separate the bottom of the dish and form at 120°C for 2 hours under a pressure of 40N; use electron beam evaporation to prepare electrodes at both ends of the film and cut the film material into a square with a side length of 1 cm; polarize at 710V and a temperature of 110°C for 3 hours to obtain Novel flexible nanogenerators.

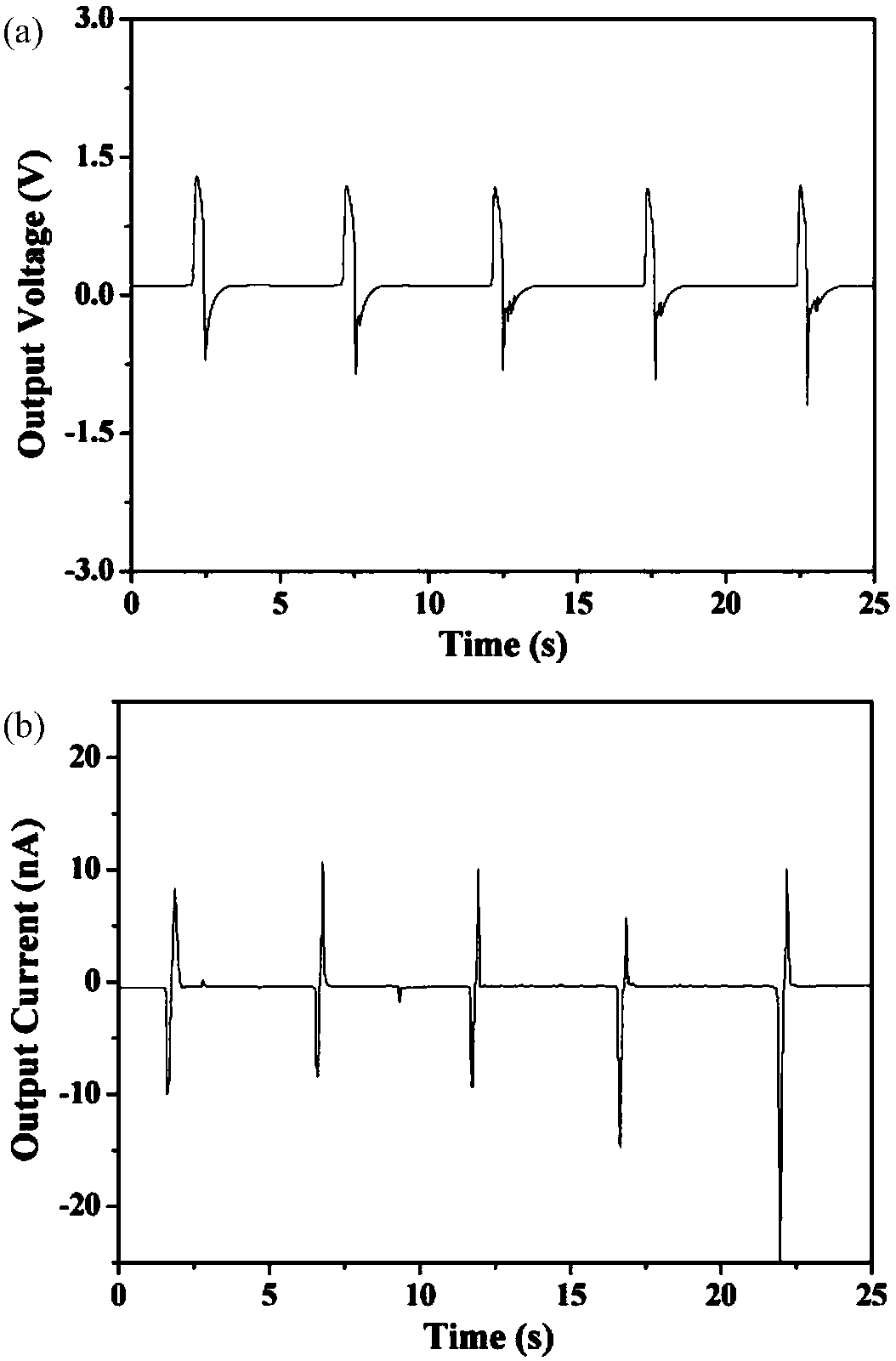

[0025] The new flexible nanogenerator produced in this example is m...

Embodiment 2

[0027] Weigh PMN-PT single crystal nanowires and PVDF powder according to the ratio of 20PMN-PT / 80PVDF, dissolve the two raw materials in 20ml DMA, and alternately act on magnetic stirring and ultrasonic dispersion for 4h until the solution is uniformly mixed; the uniformly mixed Pour the solution into a petri dish with a diameter of 10 cm and place it horizontally for 10 minutes to spread the solution evenly on the petri dish; keep the solution in a horizontal state and move it into an oven, and dry it at 60°C for 12 hours to completely evaporate the liquid; remove the obtained film from the petri dish The bottom is separated and molded at 120°C for 2 hours under a pressure of 40N; Electrodes are prepared at both ends of the film by electron beam evaporation and the film material is cut into a square with a side length of 1cm; Polarized at 710V and 110°C for 3 hours, the new type can be obtained. Flexible nanogenerators.

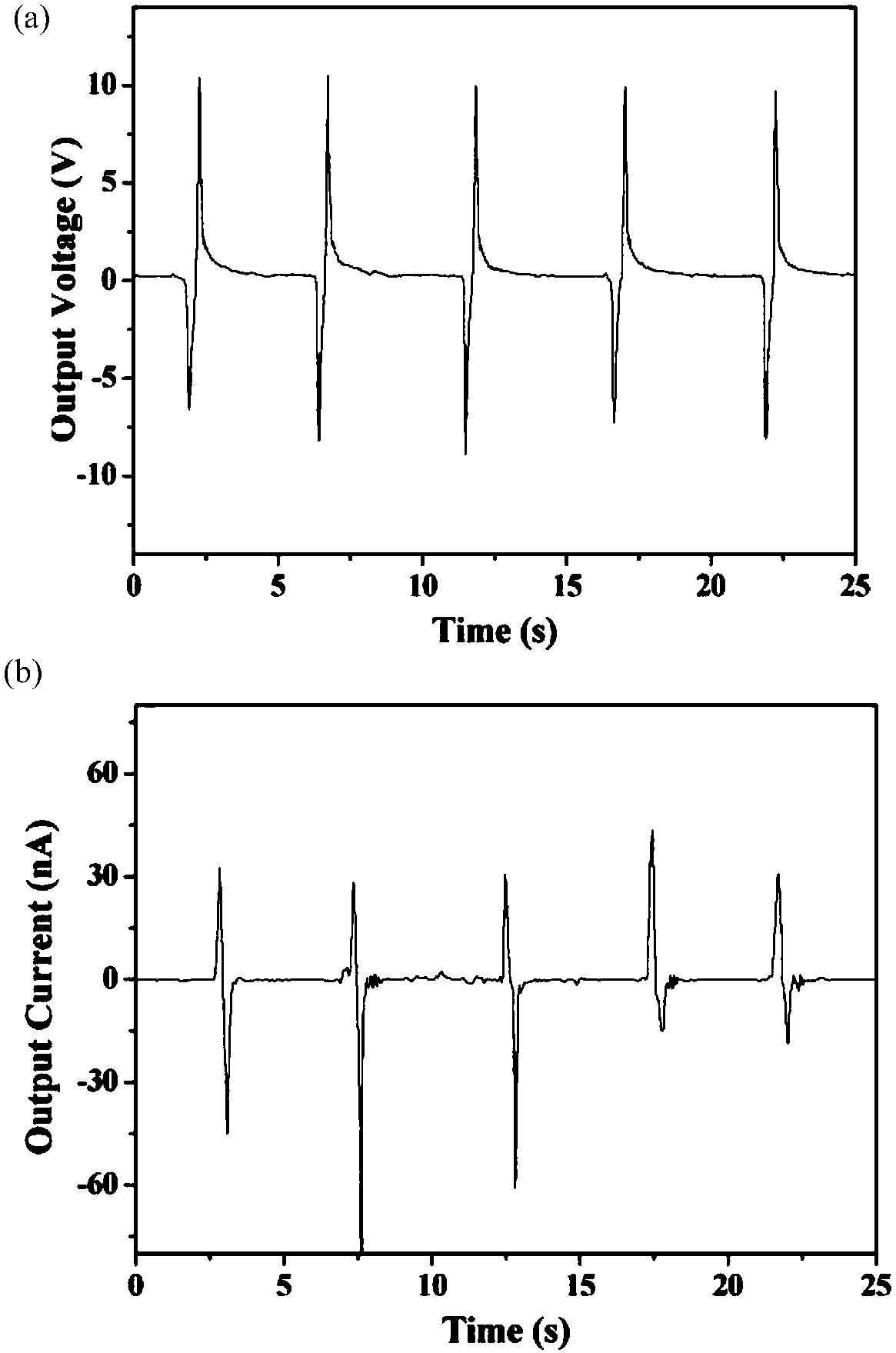

[0028] The new flexible nanogenerator produced in thi...

Embodiment 3

[0030] Weigh PMN-PT single crystal nanowires and PVDF powder according to the ratio of 25PMN-PT / 75PVDF, dissolve the two raw materials in 20ml DMA, and alternately act on magnetic stirring and ultrasonic dispersion for 4h until the solution is uniformly mixed; the uniformly mixed Pour the solution into a petri dish with a diameter of 10 cm and place it horizontally for 10 minutes to spread the solution evenly on the petri dish; keep the solution in a horizontal state and move it into an oven, and dry it at 60°C for 12 hours to completely evaporate the liquid; remove the obtained film from the petri dish The bottom is separated and molded at 120°C for 2 hours under a pressure of 40N; Electrodes are prepared at both ends of the film by electron beam evaporation and the film material is cut into a square with a side length of 1cm; Polarized at 710V and 110°C for 3 hours, the new type can be obtained. Flexible nanogenerators.

[0031] The new flexible nanogenerator produced in thi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com